Oil-gas well shaft corrosion simulation evaluation system

A technology for simulation evaluation and wellbore, which is applied in wellbore/well components, measurement, earthmoving, etc., can solve problems such as poor authenticity, and achieve the effect of easy assembly, simple simulation process, and data collection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

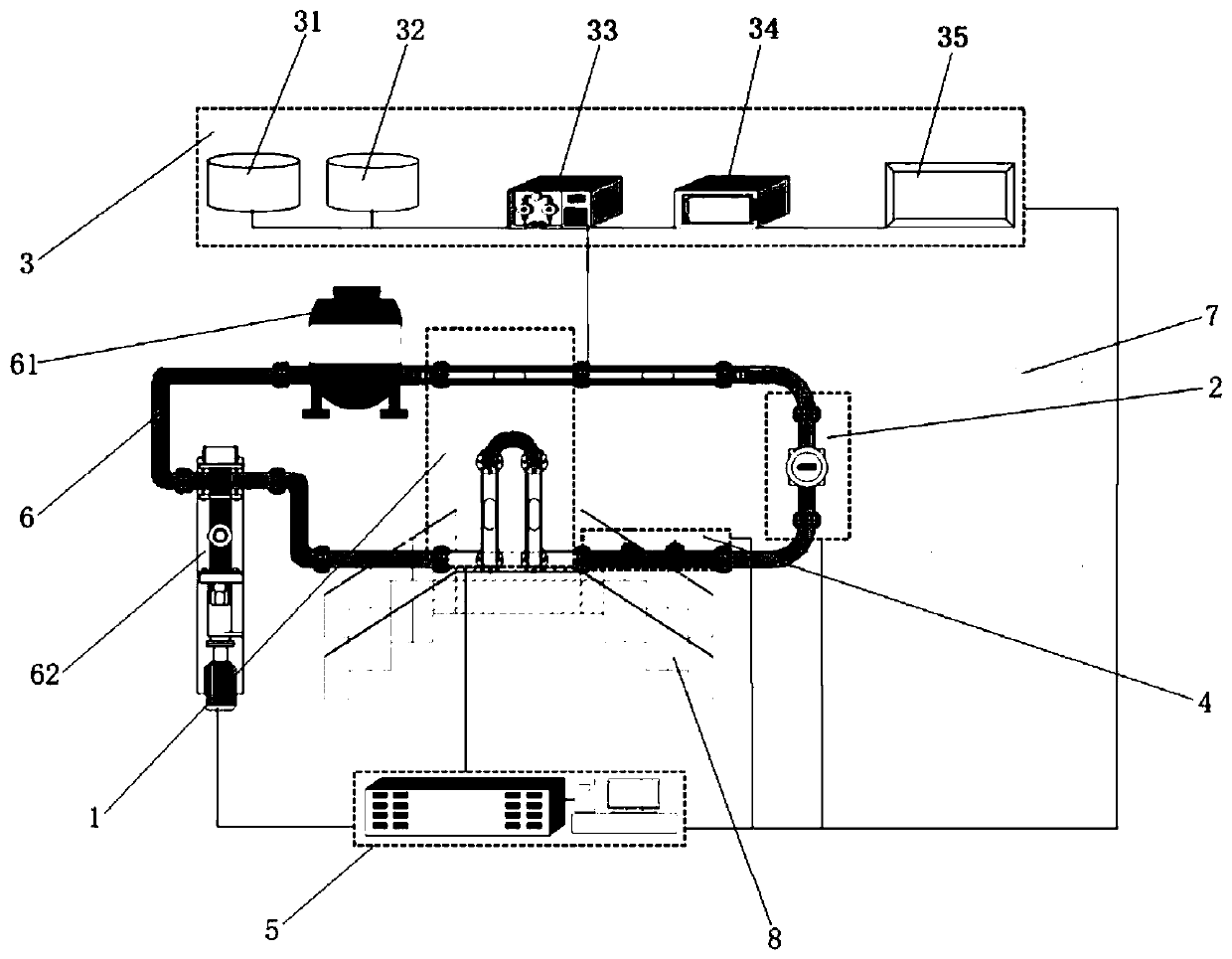

[0044] Dynamic corrosion inhibitor screening and evaluation test: store the field water sample in the liquid storage tank 61 during work, pump the liquid into the inner oil pipe until the pipe is full, and open the pipe cycle. The heating jacket is heated to the formation 55℃, constant temperature, pressure 3MPa, flow rate 0.1m / s, real-time monitoring of dynamic corrosion rate through electrochemical corrosion probe module 4, take out corrosion coupons every 3 days, weigh the difference in this time period For the uniform corrosion rate of the corrosion inhibitor, MH46 and YJH-10 corrosion inhibitors are used in this embodiment, wherein the slow-release rate of the corrosion inhibitor MH46 is 0.03 mm / a, and the slow-release rate of the corrosion inhibitor YJH-10 is 0.15 mm / a. MH46 was selected as the corrosion inhibitor suitable for oilfield water samples.

Embodiment 2

[0046] Dynamic corrosion inhibitor screening and evaluation test: store the field water sample in the liquid storage tank 61 during work, pump the liquid into the inner oil pipe until the pipe is full, and open the pipe cycle. The heating jacket is heated to 63°C, constant temperature, pressure 5MPa, and flow rate 0.2m / s. The dynamic corrosion rate is monitored in real time through the electrochemical corrosion probe module 4. In this example, KEW-227 and RX-201 corrosion inhibitors are used. The slow-release rate of corrosion inhibitor KEW-227 is 0.02mm / a, and the slow-release rate of corrosion inhibitor RX-201 is 0.11mm / a. KEW-227 was selected as the corrosion inhibitor suitable for oilfield water samples.

Embodiment 3

[0048] Dynamic scale inhibitor screening and evaluation test: store the field water sample in the liquid storage tank 61 during work, pump the liquid into the inner oil pipe until the pipe is full, and open the pipe cycle. The heating jacket is heated to the formation 46℃, constant temperature, pressure 5MPa, flow rate 0.1m / s, real-time monitoring of the dynamic scaling rate through the scaling evaluation module 3, taking out the scaling coupon every 2 days, weighing the difference in this time period The uniform scale inhibition rate of the scale inhibitor. In this example, ZG-108 and ZG-558 scale inhibitors are used. Among them, the scale inhibition rate of the scale inhibitor ZG-108 is 75.6%, and the scale inhibition rate of the scale inhibitor ZG-558 is 87.6%. . ZG-558 was selected as the scale inhibitor suitable for oilfield water samples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com