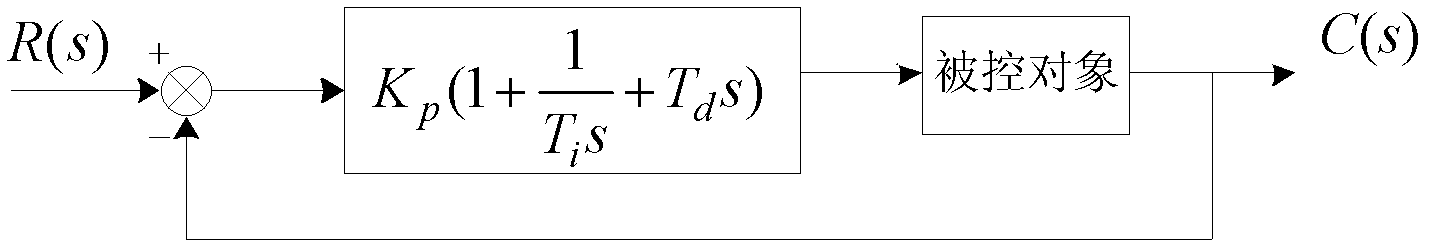

PI (Proportional Integral) parameter mixed setting method

A parameter, AC speed regulation technology, applied in the field of PID control, can solve the problems of large calculation amount and required storage space, difficult to promote and apply, etc., to improve adaptability, improve dynamic performance and steady-state accuracy, improve steady-state accuracy and The effect of speed pulsation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

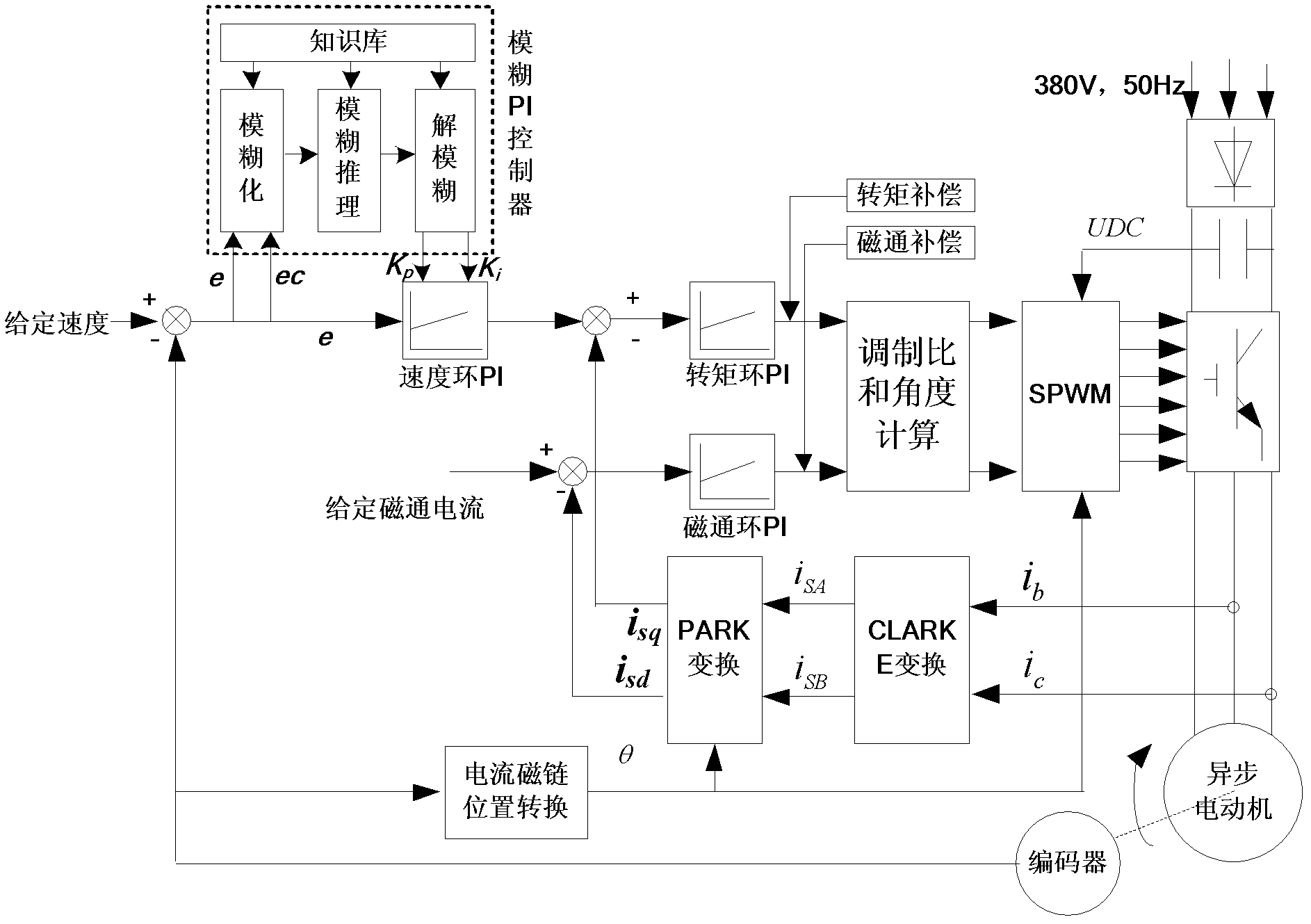

[0064] Embodiment 1: Application of PID parameter hybrid tuning method in closed-loop vector control system

[0065] 1. Closed-loop vector control system and tuning method:

[0066] The mathematical model of the asynchronous motor is a high-order, nonlinear, strongly coupled multivariable system, and the high-performance control of the asynchronous motor can be realized by using vector control.

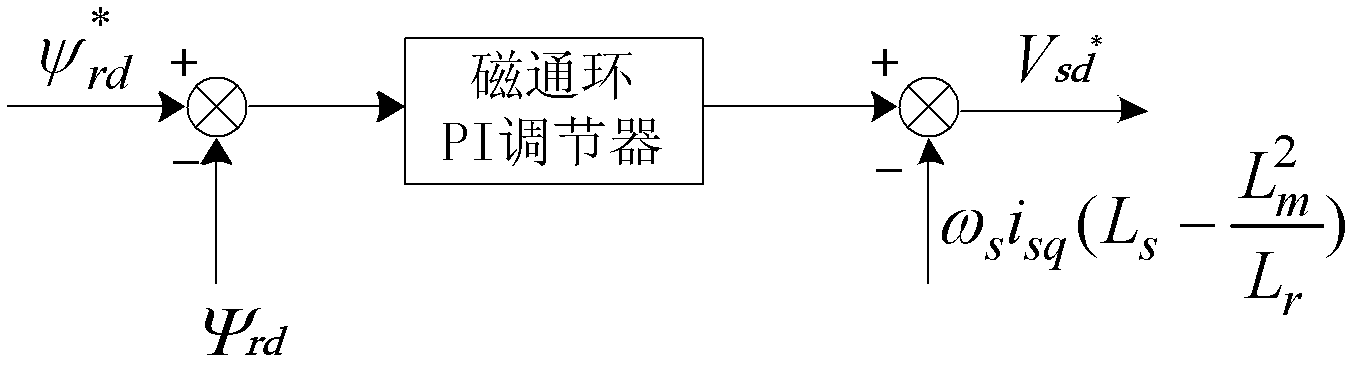

[0067] The closed-loop vector control system adopted in the present invention is as figure 2 As shown, it includes fuzzy PI controller, speed loop PI controller, flux loop PI controller, torque loop PI controller, compensation module (torque loop and flux loop compensation), modulation ratio and angle calculator, SPWM wave generating module, current flux linkage position converter, converter (CLARK change and PARK conversion), sensor (encoder and current sensor) and asynchronous motor, where: the encoder is used to measure the real-time speed of the asynchronous motor, and the curre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com