Method for preparing thermal barrier coating CMAS-alienated surface by utilizing picosecond laser

A technology of thermal barrier coating and picosecond laser, which is applied in coating, metal material coating process, etc., can solve the problems of accelerated phase change failure of coating materials, lack of resistance to CMAS, and decreased service life of thermal barrier coatings. Achieve the effect of reducing surface contact area, improving CMAS corrosion resistance, and high practical application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments will be described in detail below in conjunction with specific drawings of the present invention.

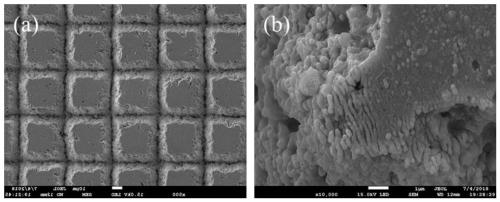

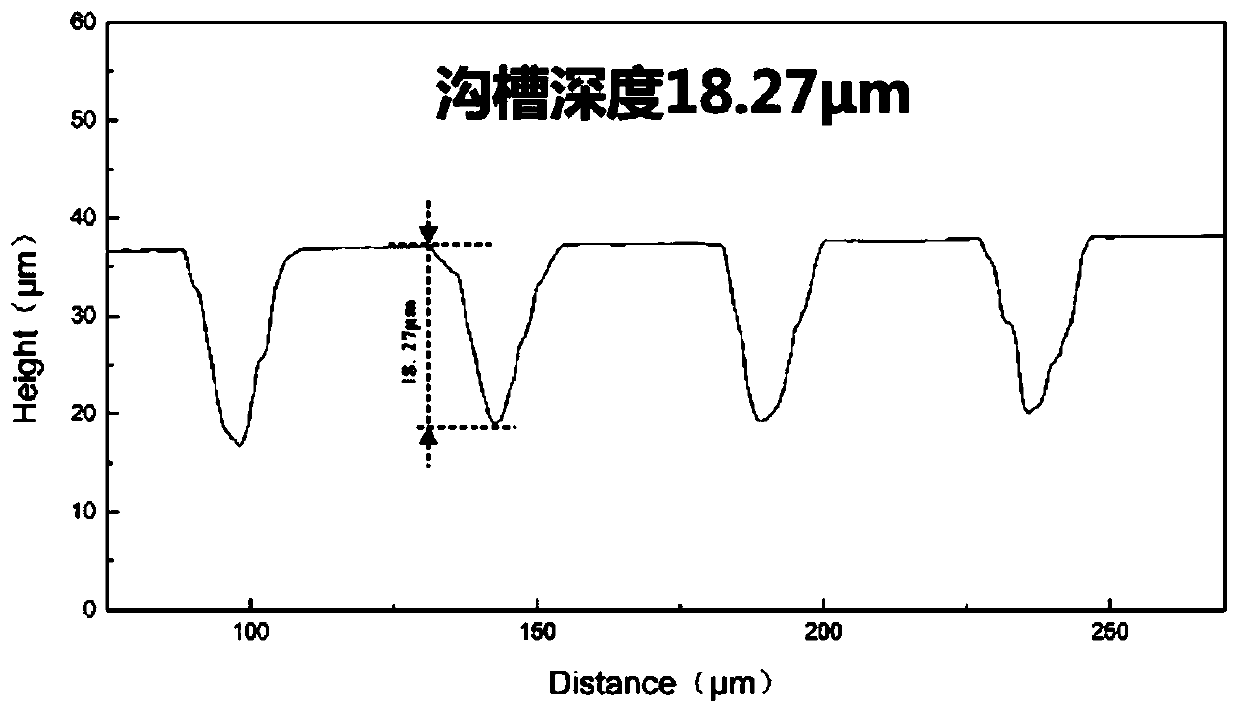

[0020] A method of preparing a thermal barrier coating away from the CMAS surface using a picosecond laser in this embodiment, the preparation method includes the following steps:

[0021] The first step: mix 8wt.%Y 2 o 3 , 92wt.% ZrO 2 The powder (99.5%, particle size about 0.5 μm) was placed in a zirconia ball milling tank, and alcohol was used as the ball milling medium, and ball milled on a planetary ball mill for 24 hours, and then the powder was taken out and dried in a drying oven at 80°C for 12 hours. The powder was pressed into discs under a pressure of 20 MPa by dry pressing method, and then the discs were placed in a high-temperature sintering furnace at 1450°C for 4 hours, and sintered to obtain 8YSZ thermal barrier coating.

[0022] Step 2: First, rough grind the 8YSZ thermal barrier coating with silicon carbide sandpaper, and then use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com