Method for improving molten CMAS corrosion resistance of thermal barrier coating through laser surface treatment

A technology of laser surface treatment and thermal barrier coating, applied in coating, fusion spraying, metal material coating process, etc., can solve the problem that the corrosion resistance of molten CMAS cannot be explained, and there is no laser modified layer to resist molten CMAS. It is completely resistant to molten salt corrosion and other problems, and achieves the effect of improving the corrosion resistance of CMAS, excellent corrosion resistance of CMAS, and improvement of corrosion resistance of CMAS.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

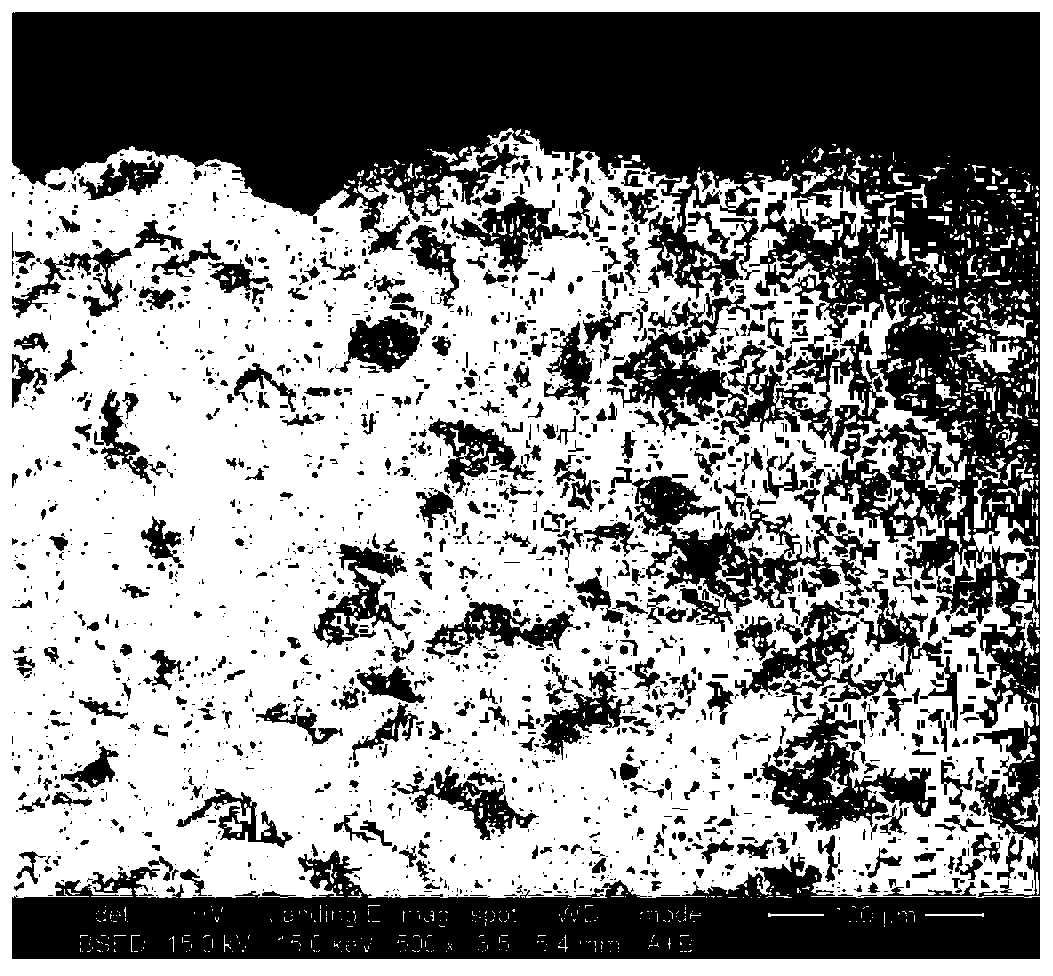

[0028] 1. Prepare a thermal barrier coating on a superalloy substrate, including a bonding layer and a ceramic coating, wherein the bonding layer first prepared on the substrate is MCrAlY (M is Ni and / or Co), prepared by supersonic flame spraying , with a thickness of 50 μm.

[0029] 2. The ceramic layer prepared on the bonding layer is yttria partially stabilized zirconia (YSZ), which is prepared by atmospheric plasma spraying method, with a thickness of 95 μm.

[0030] 3. Ultrasonic cleaning is performed on the prepared thermal barrier coating to remove surface stains and impurities.

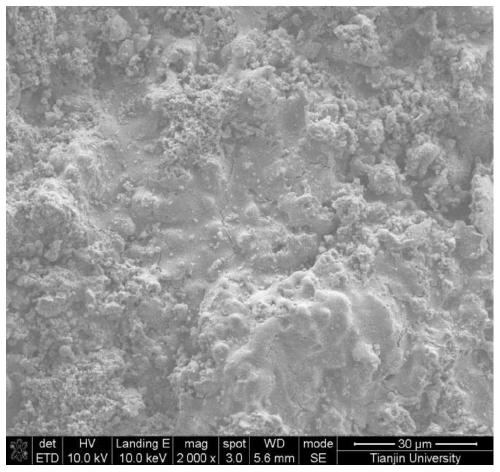

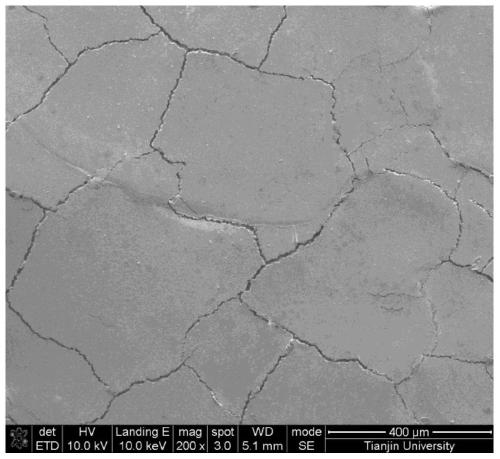

[0031] 4. The surface laser modification of the ceramic layer is carried out by using a Nd:YAG solid-state pulse laser with a rated power of 200W; a total of 16 laser paths are made on the surface of the ceramic layer, and the overlap rate of each path is 33%. The power is 80W, the frequency is 20Hz, the scan rate is 20mm / s, the spot size diameter is 2mm, and the crack density is 0.062mm -1 ...

Embodiment 2

[0038] 1. Prepare a thermal barrier coating on a high-temperature substrate, including a bonding layer and a ceramic coating, wherein the bonding layer first prepared on the substrate is MCrAlY (M is Ni and / or Co), using electron beam-physical vapor deposition method, the thickness is 45 μm.

[0039] 2. Secondly, the ceramic layer prepared on the bonding layer is yttria partially stabilized zirconia (YSZ), which is prepared by electron beam-physical vapor deposition method, with a thickness of 108 μm.

[0040] 3. Ultrasonic cleaning is performed on the prepared thermal barrier coating to remove surface stains and impurities.

[0041] 4. The surface laser modification of the ceramic layer is carried out by using a Nd:YAG solid-state pulse laser with a rated power of 200W; a total of 6 laser paths are made on the surface of the ceramic layer, the overlap rate of each path is 0, and the power in the laser parameters is 160W, frequency 40Hz, scan rate 6mm / s, spot size diameter 1mm,...

Embodiment 3

[0044] 1. Prepare a thermal barrier coating on a high-temperature substrate, including a bonding layer and a ceramic coating, wherein the bonding layer first prepared on the substrate is MCrAlY (M is Ni and / or Co), using plasma spraying-physical vapor deposition method, the thickness is 63 μm.

[0045] 2. Secondly, the ceramic layer prepared on the bonding layer is yttria partially stabilized zirconia (YSZ), prepared by atmospheric plasma spraying method, with a thickness of 114 μm.

[0046] 3. Ultrasonic cleaning is performed on the prepared thermal barrier coating to remove surface stains and impurities.

[0047] 4. The surface laser modification of the ceramic layer is carried out by using a Nd:YAG solid-state pulse laser with a rated power of 200W; a total of 10 laser paths are made on the surface of the ceramic layer, and the overlap rate of each path is 20%, and the power in the laser parameters is 80W , the frequency is 20Hz, the scan rate is 20mm / s, and the spot size ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com