Soluble magnesium-based alloy and its preparation method

A magnesium-based alloy, soluble technology, applied in earthwork drilling, wellbore/well components, mining fluids, etc., can solve problems such as difficult flowback, fracturing balls cannot dissolve by themselves, reduce segregation, improve electricity Chemical performance, effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

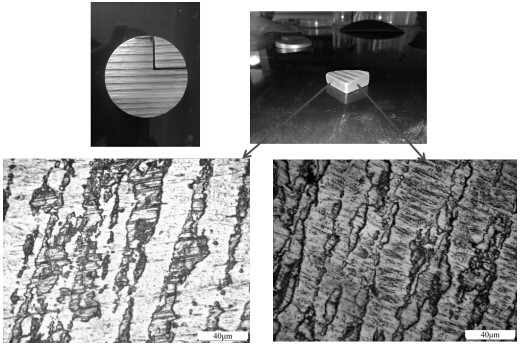

Embodiment approach 1

[0033] This embodiment provides a soluble magnesium-based alloy for preparing fracturing balls for oil and gas development, including the following components in weight percentages: Mn: 0.2%, Ca: 1%, Nb: 1%, Ge: 2%, Si: 0.2%, Hg: 1.6%, Ga: 1.0%, Dy: 0.4%, Mg: 92.6%, and the Ga / Hg ratio is 0.63.

[0034] The preparation method of the above-mentioned soluble magnesium-based alloy is as follows:

[0035] First, take the pure metals of Mg, Mn, Nb as raw materials according to the ratio, and Mg-Ca, Mg-Si, Mg-Hg, Mg--Dy, Mg-Ge, Mg with powder particles of 20~200 μm prepared by powder metallurgy. -Ga master alloy, and dry treatment of all raw materials.

[0036] S1: Smelting: in CO 2 with SF 6 In a mixed gas atmosphere with a ratio of 300:1, first melt pure magnesium, then add pure metals of Mn and Nb with a purity of ≥99.9% at 690ºC, stir evenly and keep warm for 30 minutes, then add Mg-Ca and Mg with a purity of ≥99.9% -Si, Mg-Hg, Mg-Dy, Mg-Ge, Mg-Ga master alloys, stir well, k...

Embodiment approach 2

[0044] This embodiment is roughly the same as Embodiment 1, the difference is only that (1) during S3 homogenization heat treatment, the heat treatment temperature is 380°C, and the treatment time is 30 hours; (2) the extrusion ratio during S4 extrusion is 5 ; (3) Among the components of the soluble magnesium-based alloy, Ga is 1.5%, Mg: 92.1%; among them, the ratio of Ga / Hg is 0.94.

[0045] Apart from this, this embodiment is completely the same as Embodiment 1, and details are not repeated here.

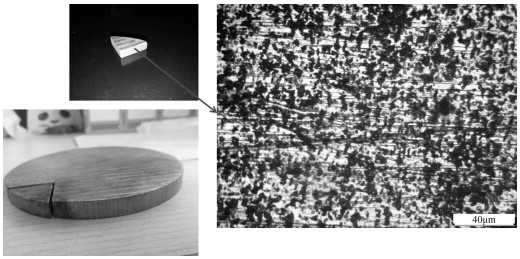

Embodiment approach 3

[0047] This embodiment is roughly the same as Embodiment 1, the difference is only that (1) during S3 homogenization heat treatment, the heat treatment temperature is 420°C, and the treatment time is 20 hours; (2) the extrusion ratio during S4 extrusion is 15 ; (3) Among the components of the soluble magnesium-based alloy, Hg is 1.5%; Ga is 1.5%, and Mg: 92.2%; among them, the Ga / Hg ratio is 1.1.

[0048] Apart from this, this embodiment is completely the same as Embodiment 1, and details are not repeated here.

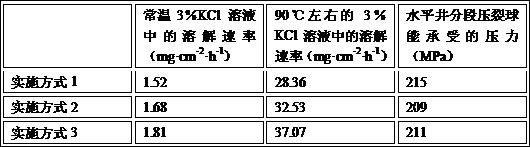

[0049] The dissolution rate of the soluble magnesium-based alloy prepared in the above-mentioned embodiments 1 to 3 in 3% KCl solution at room temperature, the dissolution rate in 3% KCl solution at about 90°C, and the pressure parameters that the staged fracturing ball of a horizontal well can withstand are as follows Table 1.

[0050] Table 1

[0051]

[0052] It can be seen from Table 1 that the dissolution rate in 3% KCl solution at room temperature and 90°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com