Heat-dissipation powder coating and preparation method thereof

A technology of powder coatings and heat-dissipating fillers, which is applied in the direction of powder coatings, anti-corrosion coatings, fire-resistant coatings, etc., can solve the problems of inability to solve the problem of filler accumulation, poor heat dissipation effect of a single heat-dissipating material, and no specific solution proposed, so as to promote Heat dissipation effect, promotion of directional arrangement, promotion of tidy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

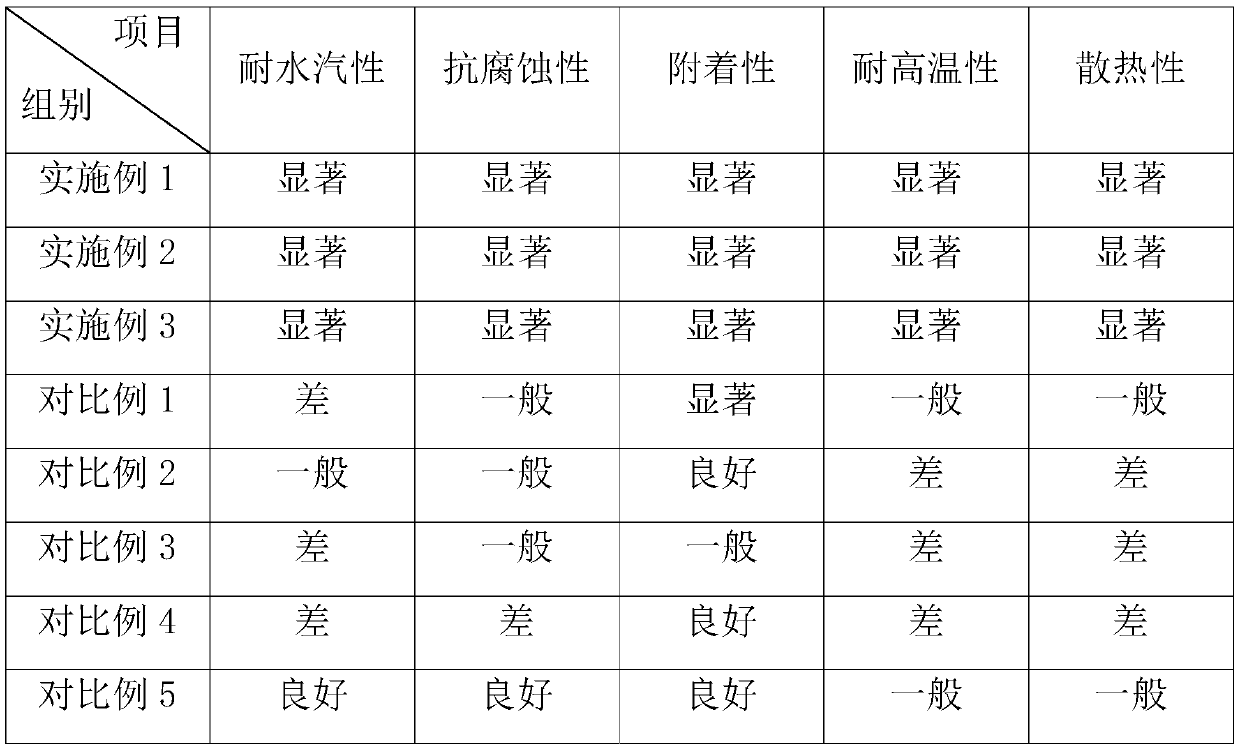

Examples

Embodiment 1

[0033] The invention provides a heat-dissipating powder coating and a preparation method thereof. The heat-dissipating powder coating comprises the following components in mass percentage: 59.3% of a saturated carboxyl-terminated polyester resin, 4.5% of a curing agent, 20.8% of a composite heat-dissipating filler, and 1% of an alignment agent , titanium dioxide 5%, leveling agent 0.5%, magnesium aluminum silicate 1%, brightener 0.5%, benzoin 0.2%, polytetrafluoroethylene 0.2%, antioxidant 0.1%, pigment 1.5%, aluminum pigment 5.4%; The composite heat-dissipating filler is prepared by successively ball milling, mixing and spheroidizing hexagonal boron nitride, aluminum hydroxide and aluminum oxide.

[0034] Wherein, in this embodiment, the saturated carboxyl-terminated polyester resin is a polyester resin with an acid value of 30-40 mgKOH / g, its addition amount is 59.3%, and the corresponding curing agent is TGIC, and the addition of the curing agent TGIC The amount is 4.5%; th...

Embodiment 2

[0044] The invention provides a heat-dissipating powder coating and a preparation method thereof. The heat-dissipating powder coating comprises the following components in mass percentage: 39.7% of saturated carboxyl-terminated polyester resin, 30% of curing agent, 13.2% of composite heat-dissipating filler, and 1% of orientation alignment agent , titanium dioxide 5%, leveling agent 1.0%, magnesium aluminum silicate 1%, brightener 0.3%, benzoin 0.5%, polytetrafluoroethylene 0.2%, antioxidant 0.3%, pigment 1.0%, aluminum pigment 6.8%; The composite heat-dissipating filler is prepared by successively ball milling, mixing and spheroidizing hexagonal boron nitride, aluminum hydroxide and aluminum oxide.

[0045] Wherein, in this embodiment, the saturated carboxyl-terminated polyester resin is a polyester resin with an acid value of 30-75 mgKOH / g, its addition amount is 39.7%, and the corresponding curing agent is an epoxy resin, and the epoxy resin The added amount is 30%; the lev...

Embodiment 3

[0055] The invention provides a heat-dissipating powder coating and a preparation method thereof. The heat-dissipating powder coating comprises the following components in mass percentage: 34.5% of a saturated carboxyl-terminated polyester resin, 18% of a curing agent, 15.5% of a composite heat-dissipating filler, and 2% of an alignment agent , titanium dioxide 5%, leveling agent 0.6%, magnesium aluminum silicate 1%, brightener 0.1%, benzoin 0.3%, polytetrafluoroethylene 0.4%, antioxidant 0.2%, pigment 1.0%, aluminum pigment 10.4%; The composite heat-dissipating filler is prepared by successively ball milling, mixing and spheroidizing hexagonal boron nitride, aluminum hydroxide and aluminum oxide.

[0056] Wherein, in this embodiment, the saturated carboxyl-terminated polyester resin is a polyester resin with an acid value of 30-75 mgKOH / g, its addition amount is 34.5%, and the corresponding curing agent is an epoxy resin, and the epoxy resin The added amount is 18%; the level...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com