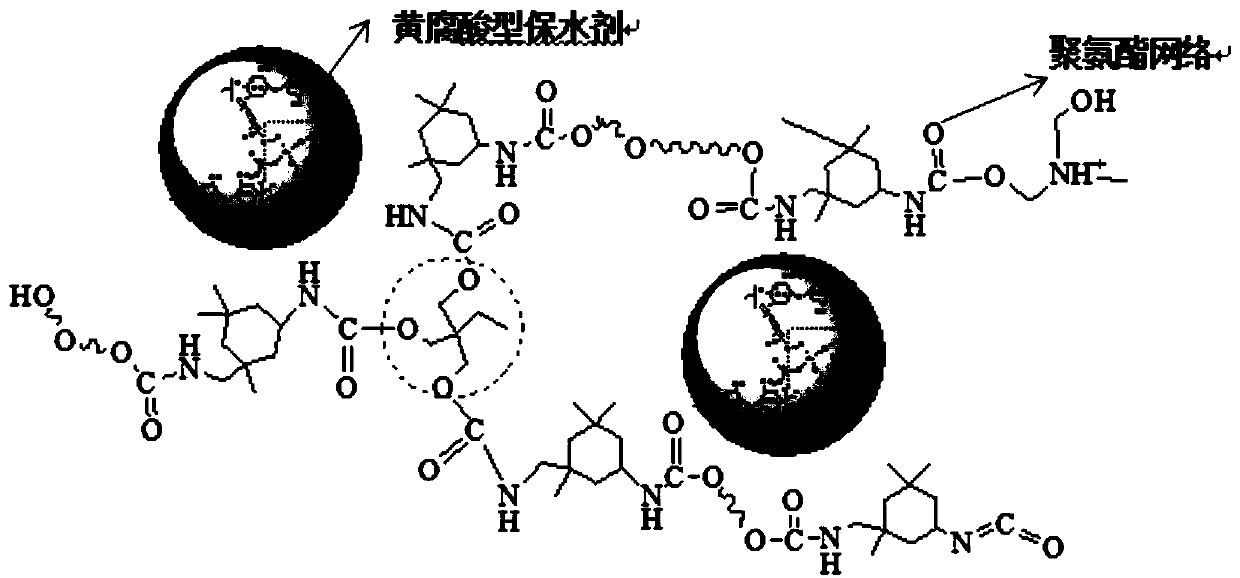

Composite fulvic acid antibacterial sponge matrix and preparation method and application thereof

A fulvic acid and composite technology, which is applied to the composite fulvic acid antibacterial sponge matrix and the field of preparation thereof, can solve the problems of decreased greening rate, rotten roots of plants, increased production cost, etc. The effect of promoting crop growth and improving stress resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Weigh 3 parts of 10% fulvic acid solution, 6 parts of acrylic acid with a neutralization degree of 50%, and 2 parts of antibacterial natural macromolecular chitosan solution, add them to a three-necked flask with a water bath temperature of 50°C, stir to fully dissolve, Continue to stir at a speed of 300r / min and raise the temperature to 70°C at a speed of 2°C / min. At the same time, dropwise add 7 parts of an aqueous solution containing 0.5 parts of potassium persulfate and 0.2 parts of KH550 dissolved in advance at a speed of 1 drop / s. After reacting for 2 hours, it was dried and crushed into fulvic acid water-retaining agent particles with a particle size of less than 1mm. In addition, 5 parts of polytetrahydrofuran and 15 parts of N-methylpyrrolidone were weighed and mixed, and then 0.3 part of dibutyltin dilaurate, 0.5 part of trimethylolpropane, and 0.5 part of N-methyldiethanolamine were added to a dry three-necked flask. Heat and stir in a water bath at 65°C for ...

Embodiment 2

[0035] Take by weighing 4 parts of 12% fulvic acid solution, 7 parts of acrylic acid with a neutralization degree of 50%, 2 parts of chitosan as a natural antibacterial macromolecule, add to a three-necked flask with a water bath temperature of 50 ° C, and continue to use 300 r / Stir at a speed of 1 min and heat up to 70 °C at a speed of 2 °C / min. At the same time, dropwise add 8 parts of an aqueous solution containing 0.6 parts of potassium persulfate and 0.2 parts of KH550 dissolved in advance at a speed of 1 drop / s, and react for 1.5 hours. Fulvic acid water-retaining agent particles that are crushed into particles with a particle size of less than 1 mm are dried. Weigh 6 parts of polytetrahydrofuran, 15 parts of N-methylpyrrolidone, 0.3 parts of dibutyltin dilaurate, 0.5 parts of trimethylolpropane, and 0.6 parts of chain extender into a dry three-necked flask, and heat it in a water bath at 65°C Stir for 10 minutes to fully dissolve, start the stirring device to stir at ...

Embodiment 3

[0037] Weigh 6 parts of 15% fulvic acid solution, 10 parts of acrylic acid with a neutralization degree of 40%, 4 parts of chitosan, peanut shell extract, and coconut shell extract concentrate antibacterial in a mass ratio of 2:1:1 Add the natural macromolecules into a three-necked flask with a water bath temperature of 55°C, stir to fully dissolve, continue to stir at a speed of 400r / min and raise the temperature to 75°C at a speed of 2°C / min, and drop at a speed of 1 drop / s Add 8 parts of pre-dissolved aqueous solution containing 0.5 parts of potassium persulfate and 0.3 parts of KH550, react for 1.5 hours, dry and pulverize into fulvic acid water retaining agent particles with a particle size of less than 1 mm. In addition, 6 parts of polytetrahydrofuran and 18 parts of N-methylpyrrolidone were weighed and mixed, and then 0.5 part of dibutyltin dilaurate, 0.6 part of trimethylolpropane, and 0.8 part of N-methyldiethanolamine were added to a dry three-necked flask. Heat and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com