A kind of medical composite material and its manufacturing process

A composite material and medical technology, applied in the field of medical materials, can solve the problems of inability to provide medical staff and patients with safety protection, high cost of use, low moisture permeability, etc., achieve good moisture permeability, reduce single Cost of use and effect of avoiding surgical risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

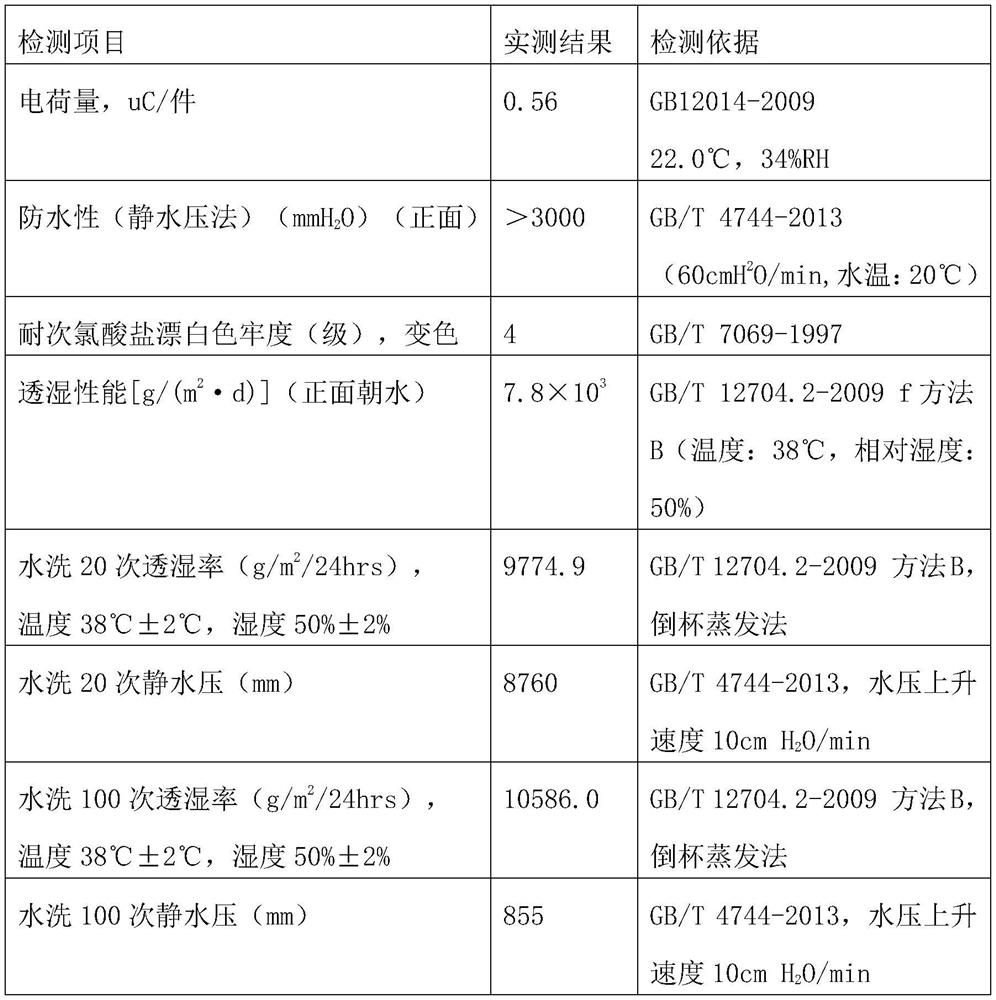

Examples

example 1

[0027] Example 1: A medical composite material and its manufacturing process

[0028] The medical composite material consists of the following parts by weight:

[0029] 60 parts of polyethylene terephthalate fiber, 10 parts of carbon ion filament fiber, 20 parts of polyurethane film and 10 parts of auxiliary material; the auxiliary material is polyurethane glue.

[0030] The manufacturing process of the above-mentioned medical composite material, the specific steps are as follows:

[0031] (1) Manufacture polyester filament fiber, make preliminary improvement to polyester filament fiber, use air deformation process to make polyester filament fiber surface reduce texture hard, smooth degree; Described polyester filament fiber is poly Ethylene phthalate (PET) filament fiber;

[0032] (2) Manufacture of conductive silk fibers

[0033] Use polyester filament fibers with round fiber cross-sections to fully infiltrate carbon ions into polyester filament fibers; then use a coating...

example 2

[0039] Example 2: A medical composite material and its manufacturing process

[0040] The medical composite material consists of the following parts by weight:

[0041] 63 parts of polyethylene terephthalate fiber, 12 parts of carbon ion filament fiber, 22 parts of polyurethane film and 13 parts of auxiliary material; the auxiliary material is polyurethane glue.

[0042] The manufacturing process of the above-mentioned medical composite material, the specific steps are as follows:

[0043] (1) Manufacture polyester filament fiber, make preliminary improvement to polyester filament fiber, use air deformation process to make polyester filament fiber surface reduce texture hard, smooth degree; Described polyester filament fiber is poly Ethylene phthalate (PET) filament fiber;

[0044] (2) Manufacture of conductive silk fibers

[0045] Use polyester filament fibers with round fiber cross-sections to fully infiltrate carbon ions into polyester filament fibers; then use a coating...

example 3

[0051] Example 3: A medical composite material and its manufacturing process

[0052] The medical composite material consists of the following parts by weight:

[0053] 56 parts of polyethylene terephthalate fiber, 9 parts of carbon ion filament fiber, 18 parts of polyurethane film and 8 parts of auxiliary material; the auxiliary material is polyurethane glue.

[0054] The manufacturing process of the above-mentioned medical composite material, the specific steps are as follows:

[0055] (1) Manufacture polyester filament fiber, make preliminary improvement to polyester filament fiber, use air deformation process to make polyester filament fiber surface reduce texture hard, smooth degree; Described polyester filament fiber is poly Ethylene phthalate (PET) filament fiber;

[0056] (2) Manufacture of conductive silk fibers

[0057] Use polyester filament fibers with round fiber cross-sections to fully infiltrate carbon ions into polyester filament fibers; then use a coating p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com