Soil sample grinding and screening device

A screening device and sample technology, applied in measurement devices, sampling, analysis of materials, etc., can solve problems affecting the accuracy of soil sample detection results, dust pollution of the environment, screening errors, etc., to improve screening stability, reduce Pollution, improve the effect of screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

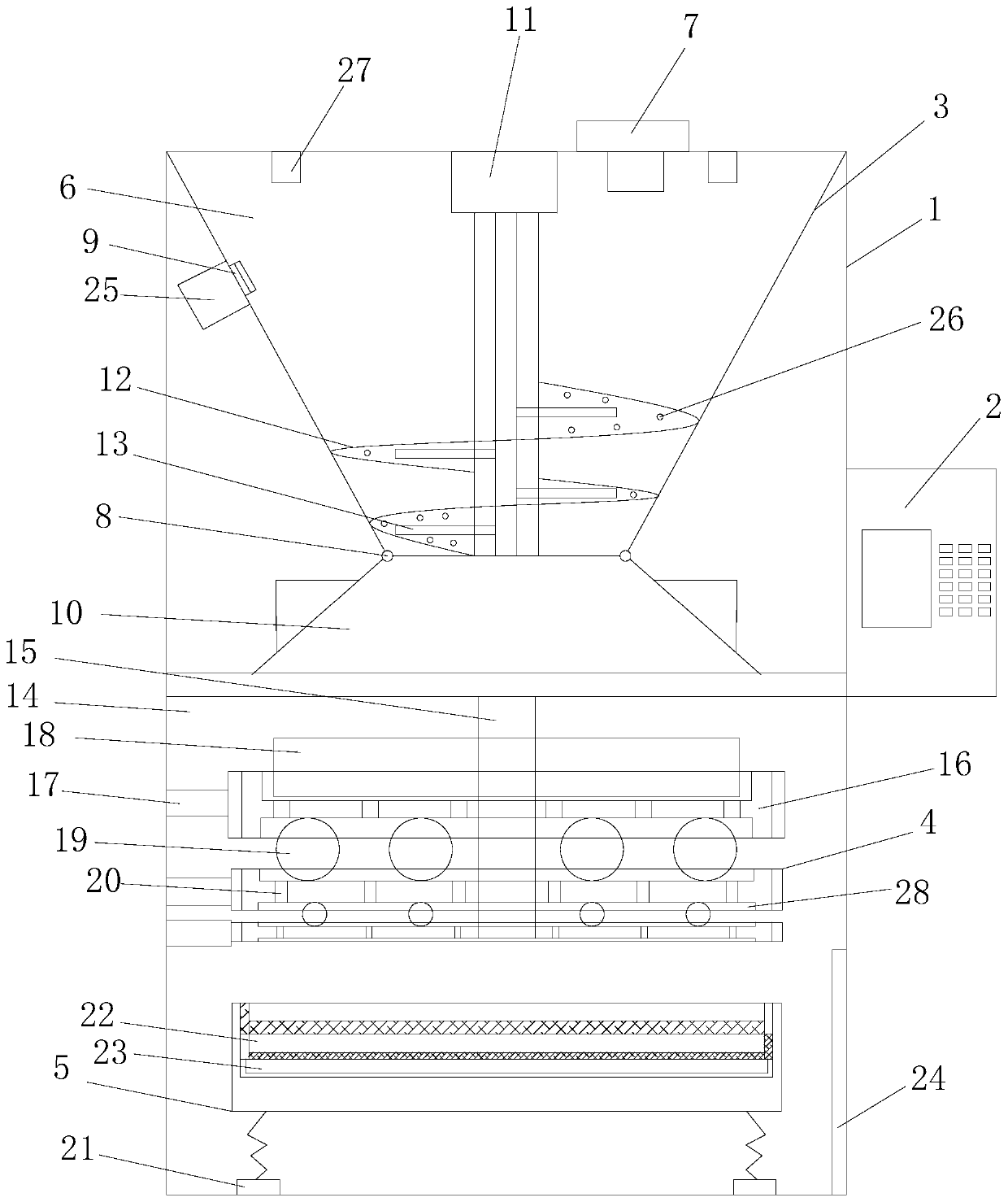

[0017] refer to figure 1 , a soil sample grinding and screening device of the present invention, comprising a frame 1, a control center 2, a drying and crushing mechanism 3, a layered grinding mechanism 4, and a fine sieve discharging mechanism 5, the top of the frame 1 is provided with a drying The crushing mechanism 3, the drying and crushing mechanism 3 includes a sealed container 6, a sealed feed port 7, an electric discharge port 8, a one-way exhaust port 9, a material guide pipe 10, a stirring motor 11, and a stirring and crushing paddle 12 , Inner heating network pipe 13, the top of the sealed material tank 6 is provided with a sealed feed inlet 7, the inside of the sealed material tank is provided with a stirring and crushing paddle 12, and the stirring and crushing paddle 12 is installed on the stirring motor 11 , the stirring and crushing paddle 12 is a heat conduction paddle, a number of internal heating network pipes 13 are interspersed in the stirring and crushing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com