Heating device for food processing

A heating device and food processing technology, which can be used in household heating, heating methods, household heating, etc., can solve the problems of wasting thermal energy, speeding up equipment aging, and scaling affecting heat conduction efficiency, reducing energy consumption and maintaining heat exchange. Efficiency, avoid premature aging damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

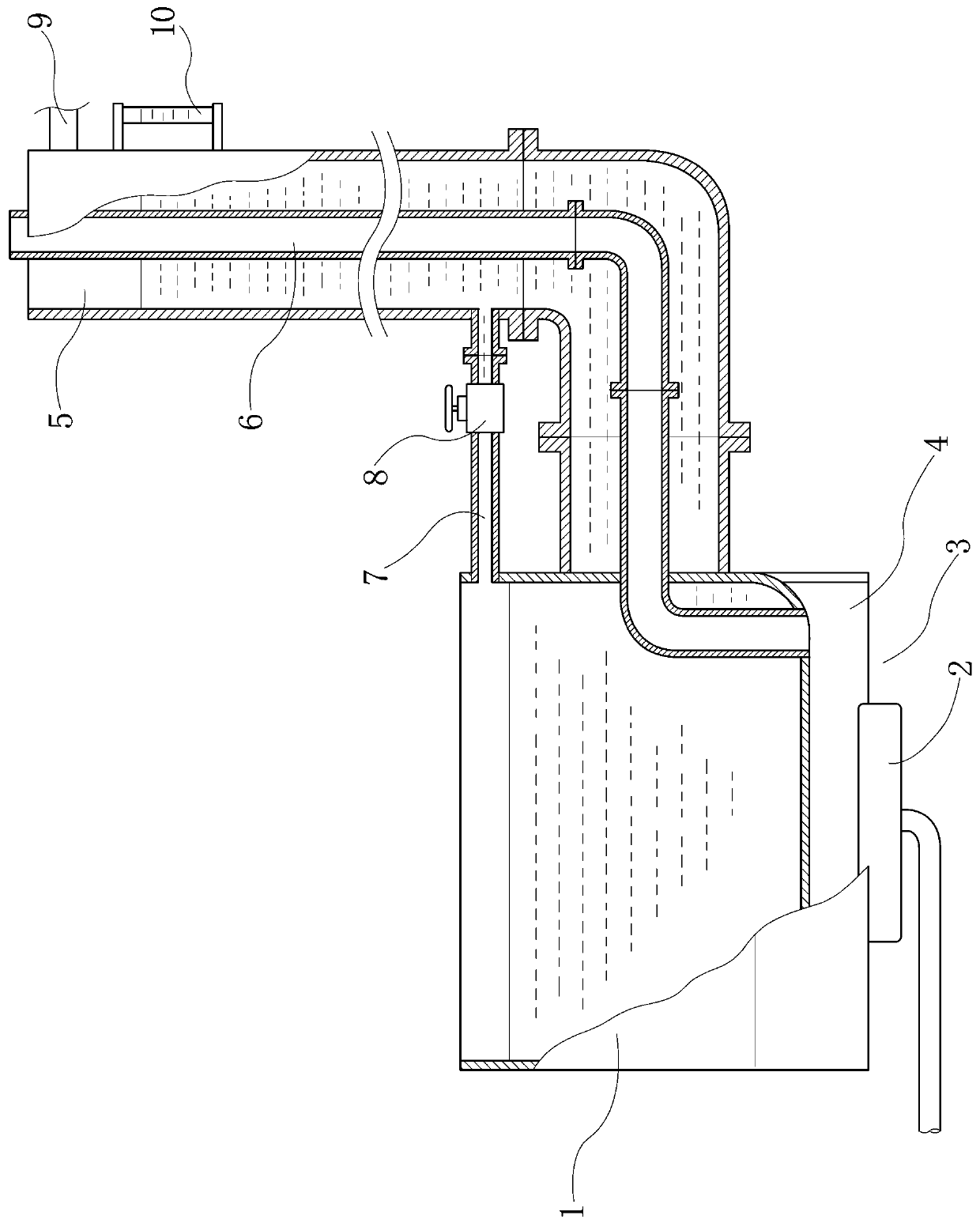

[0031] from figure 1 It can be seen that the technical solution of the present invention includes a burner, a main water tank 1 , a preheating water tank 5 , a water supply pipe 7 , and at least one smoke exhaust pipe 6 .

[0032] The top of the main water tank 1 is open, the bottom of the main water tank 1 is a combustion part, and the burner burner 2 is arranged on the combustion part 3; Body, the side wall of the main water tank 1 and the pipe wall junction of the smoke exhaust pipe 6 are fixedly connected by welding; The combustion part 3 is connected, and the rear pipe body of the smoke exhaust pipe located outside the main water tank is assembled into an L shape by a multi-section pipe body through a flange or bayonet detachable connection and extends upward;

[0033] The preheating water tank 5 also adopts a split structure of multi-section boxes, and the boxes of each section are detachably connected into one body through flanges or bayonet joints, and are set in the ...

Embodiment 2

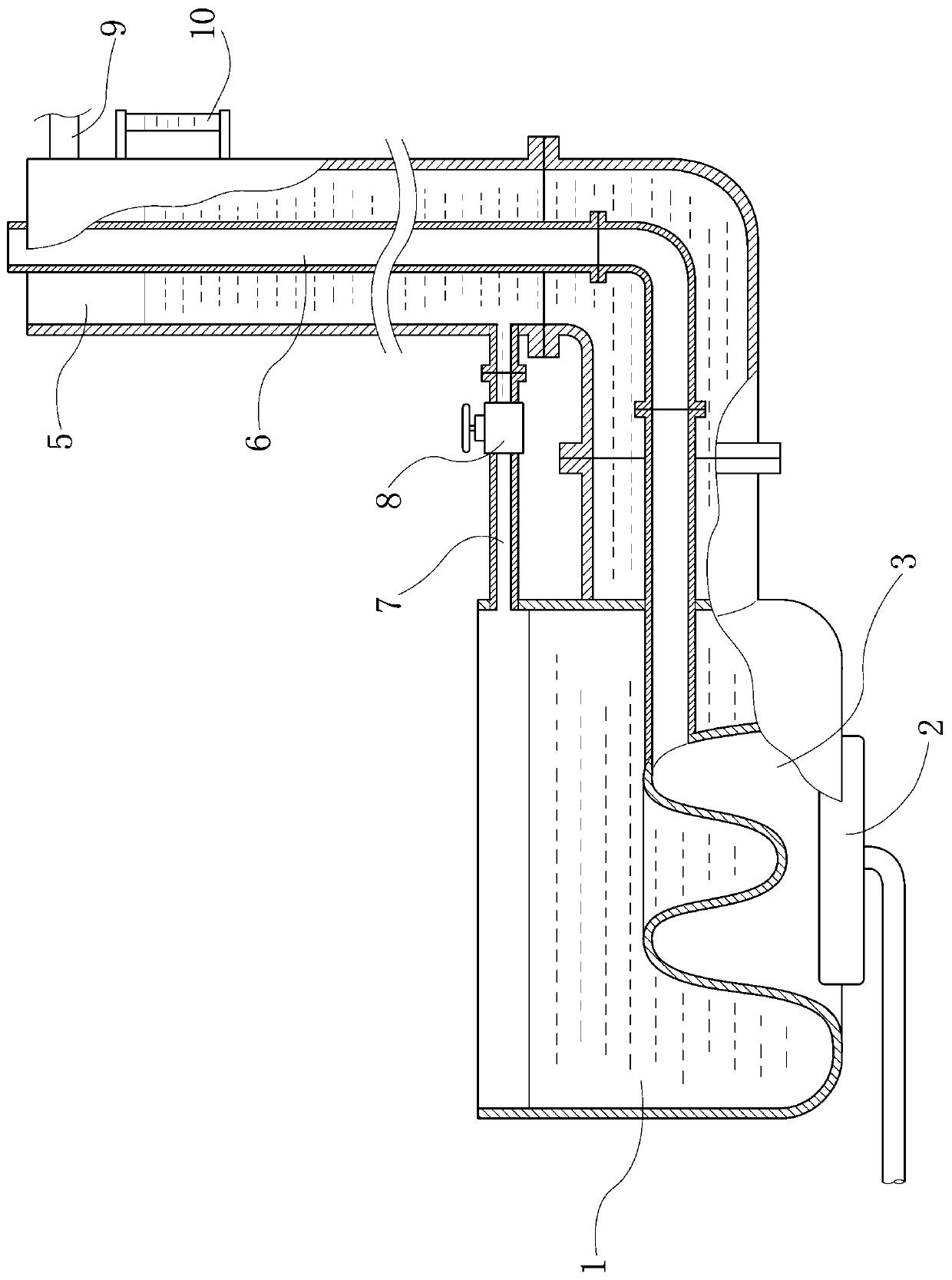

[0040] from figure 2 It can be seen that the difference between this embodiment and Embodiment 1 is that the bottom plate of the main water tank 1 is in a concave shape, which increases the heated area at the bottom of the main water tank, so that the lower part of the main water tank 1 naturally forms a combustion area (i.e. combustion part), in order to achieve the purpose of collecting smoke and avoiding heat loss. In this embodiment, the bottom plate of the main water tank 1 is designed as a plate with a wavy cross-section, which further increases the heated area of the bottom of the tank.

[0041] Other features of this embodiment are the same as Embodiment 1.

Embodiment 3

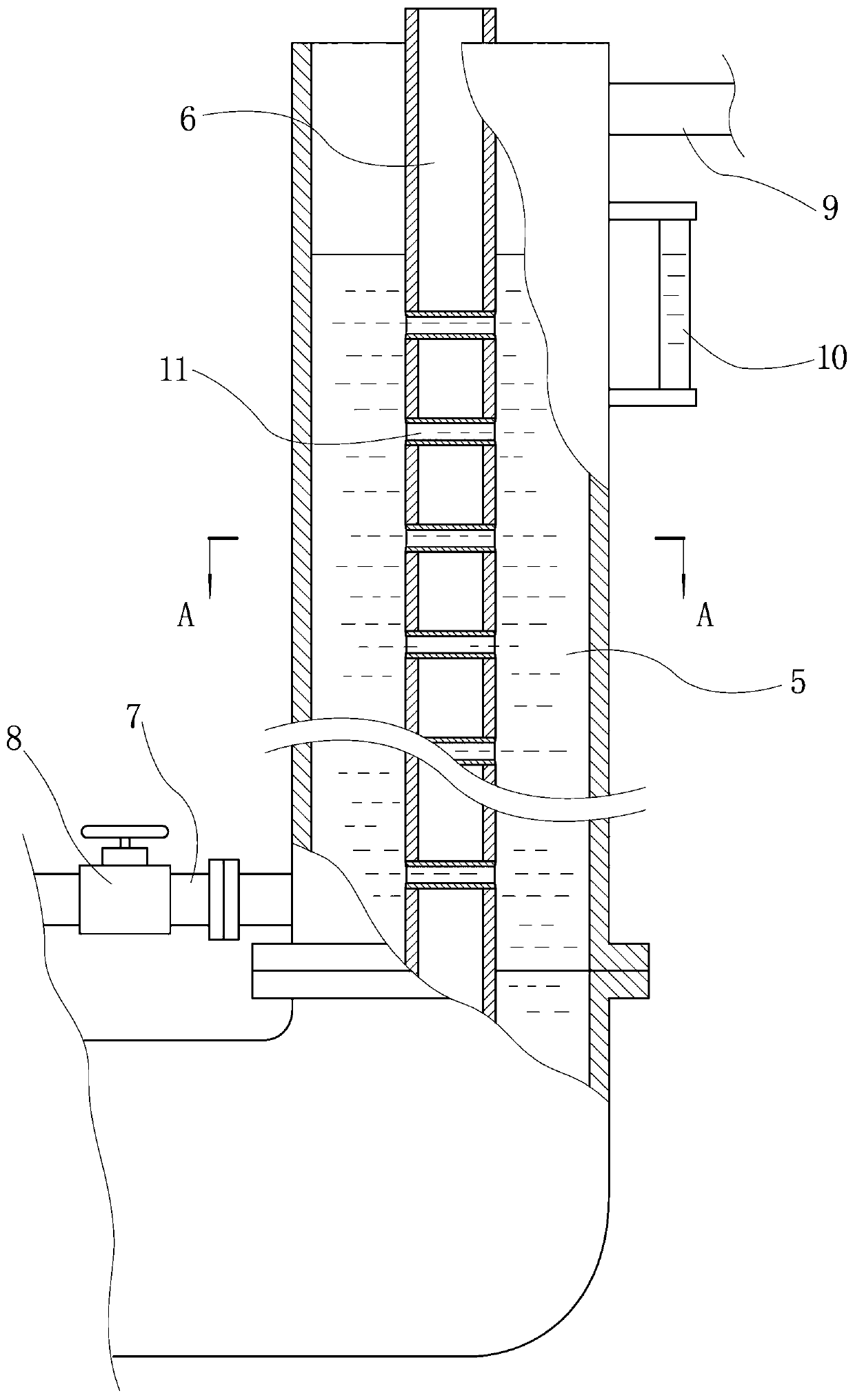

[0043] from Figure 3 ~ Figure 4 It can be seen that the difference between this embodiment and Embodiment 1 is that the outer section of the smoke exhaust pipe 6 is provided with a plurality of water pipes 11 that run through the smoke exhaust pipe transversely, and the two ports of the water pipe 11 are connected with the smoke exhaust pipe 6. The pipe wall is welded and connected so that the two ends of the water pipe are communicated with the preheating water tank 5 to increase the fluidity of the water in the tank and make full use of the waste heat of the exhaust pipe exhaust gas to heat up the spare water in the preheating water tank.

[0044] Another difference between this embodiment and Embodiment 1 is that a fan is installed at the end of the exhaust pipe 6 as a forced air exhaust device, so as to enhance the gas flow of the exhaust pipe and the combustion part and prevent the fuel from burning. full.

[0045] In addition, according to the use of the heating device, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com