Plate cooler and method of use

A plate cooler and protective plate technology, applied in the direction of indirect heat exchangers, heat exchanger types, heat exchanger shells, etc., can solve the problems of negative impact on heating units, affecting heating effect, and poor adaptability, etc., to achieve Keep the wind resistance constant, keep the heat exchange efficiency and thermal energy, and the effect of high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

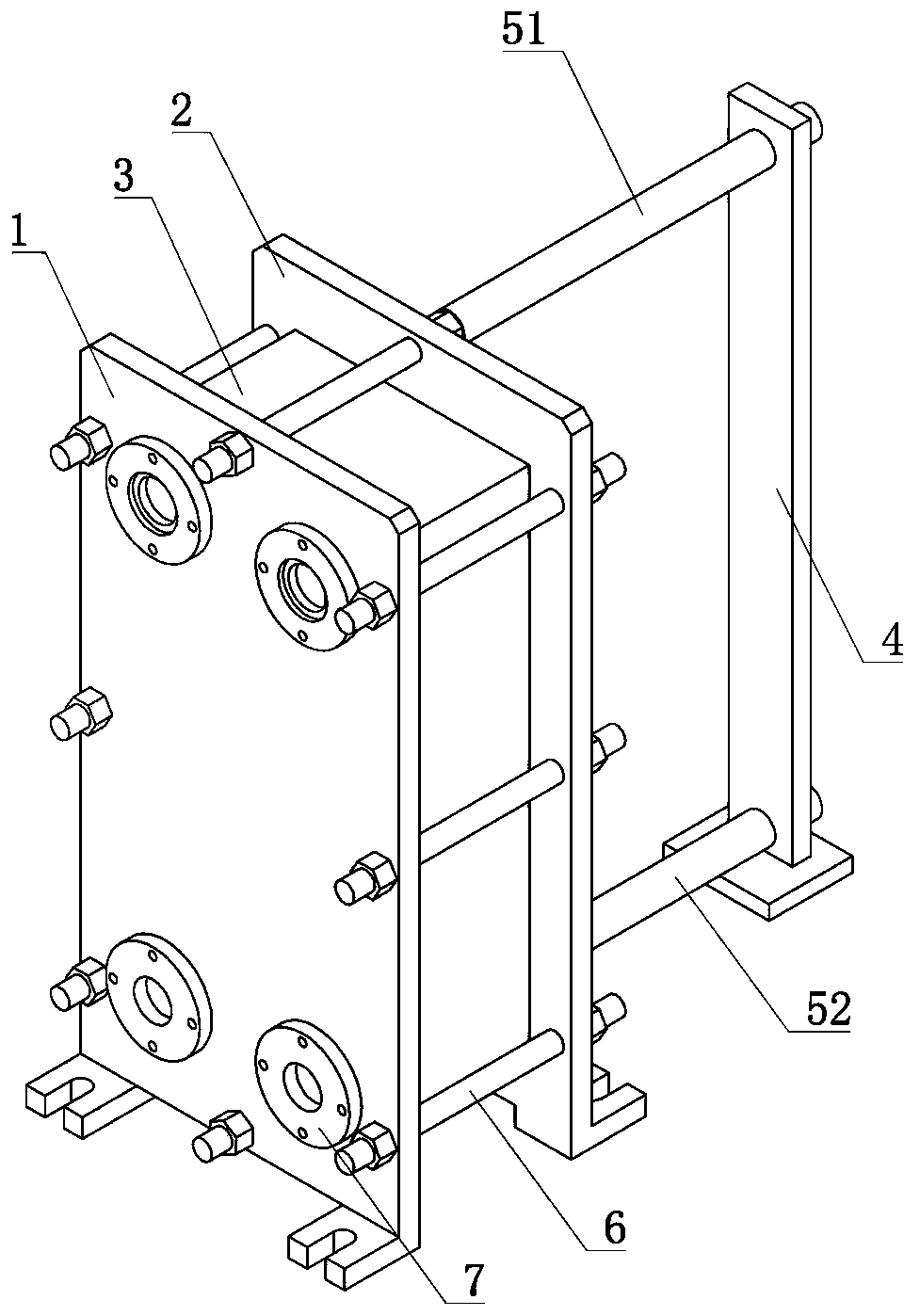

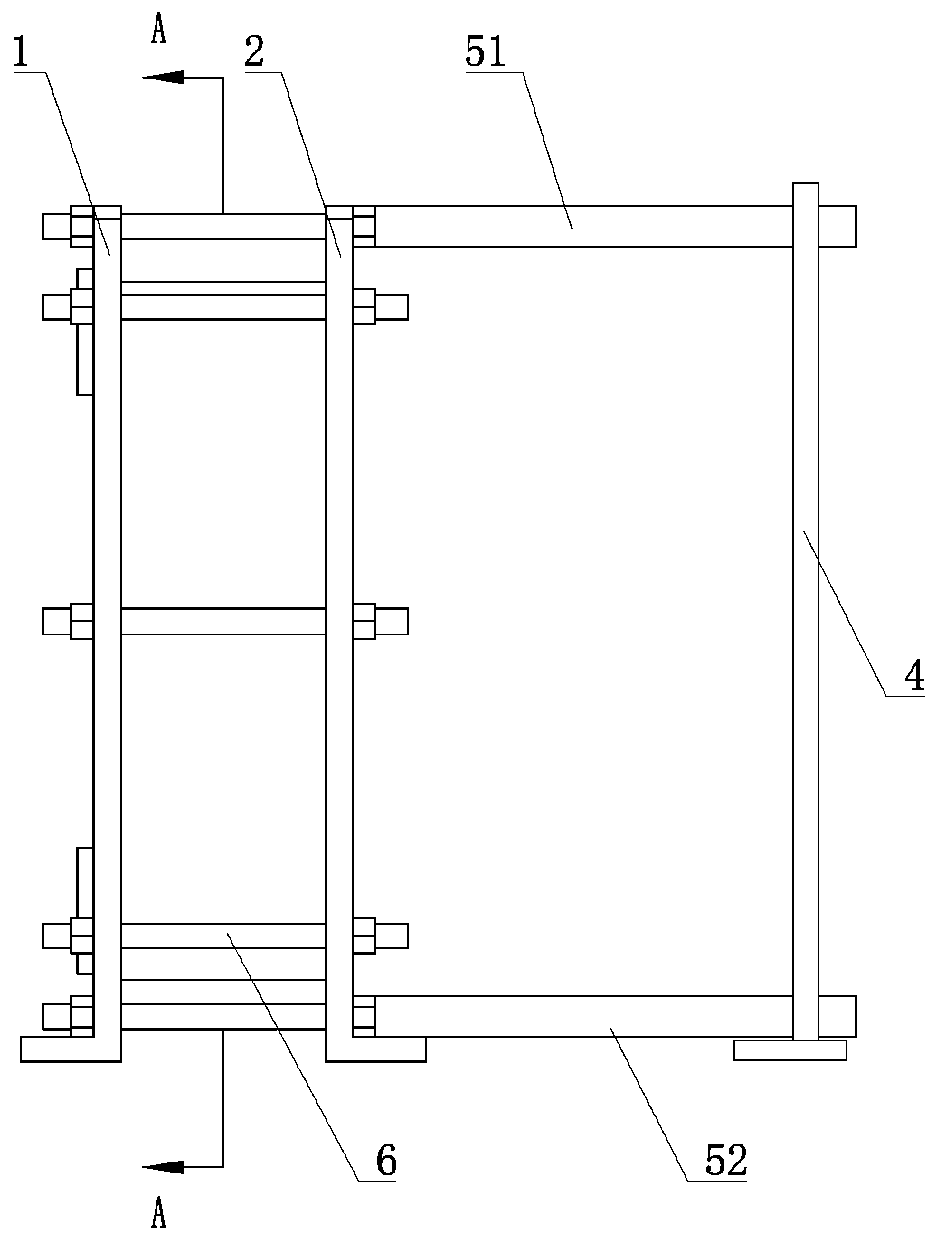

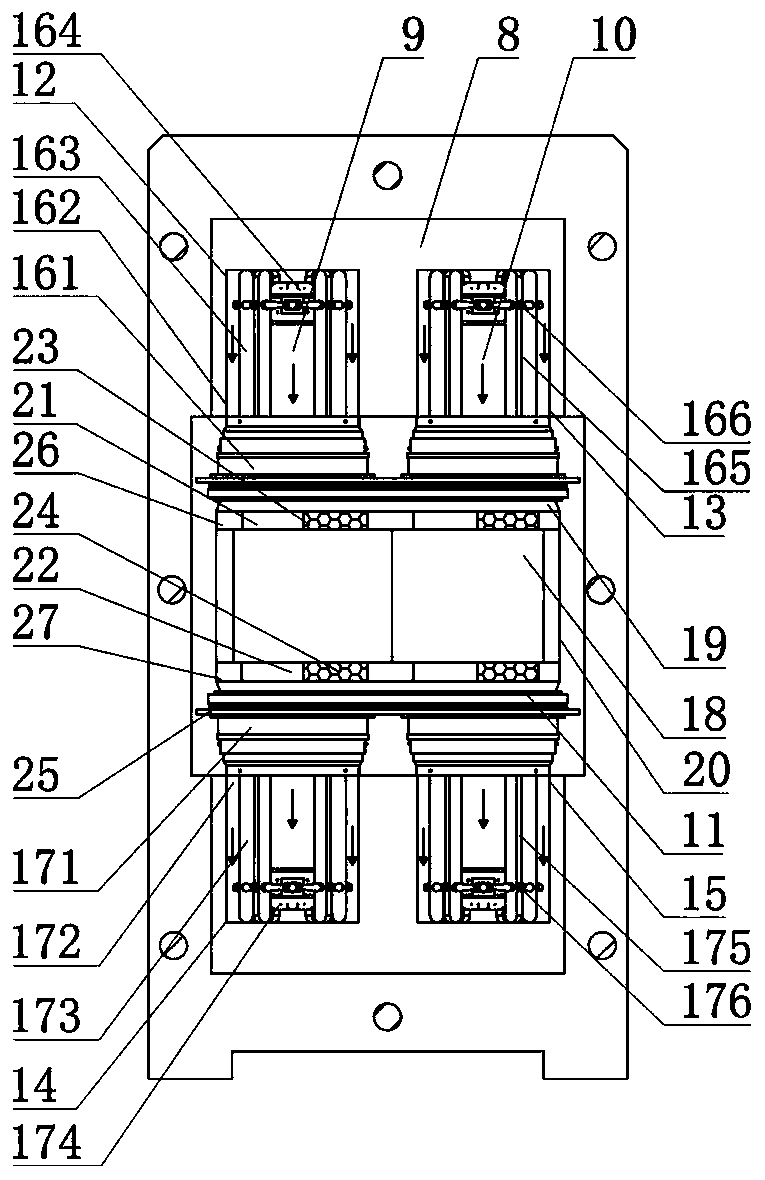

[0047] Such as figure 1 , figure 2 , image 3 As shown, the plate cooler includes a front fixed frame plate 1, a rear fixed frame plate 2, a protection plate 3, a heat exchange plate group, a supporting foot 4, an upper guide rod 51, a lower guide rod 52, tension bolts 6, monitoring The hole cover 7, the front fixed frame plate 1 is installed in front of the protective plate 3, the rear fixed frame plate 2 is installed behind the protective plate 3, the heat exchange plate group is built in the protective plate 3, the upper guide rod 51 runs through the protective plate 3, and the rear end extends out The rear fixed frame plate 2 is connected to the upper end of the support foot 4, the lower guide rod 52 runs through the protection plate 3, and the rear end extends out. The rear fixed frame plate 2 is connected to the lower end of the support foot 4, and the upper guide rod 51 is symmetrical to the lower guide rod 52 Parallel arrangement; the middle area of the front fixe...

Embodiment 2

[0059] Such as figure 1 , figure 2 , image 3 As shown, the plate cooler includes a front fixed frame plate 1, a rear fixed frame plate 2, a protection plate 3, a heat exchange plate group, a supporting foot 4, an upper guide rod 51, a lower guide rod 52, tension bolts 6, monitoring The hole cover 7, the front fixed frame plate 1 is installed in front of the protective plate 3, the rear fixed frame plate 2 is installed behind the protective plate 3, the heat exchange plate group is built in the protective plate 3, the upper guide rod 51 runs through the protective plate 3, and the rear end extends out The rear fixed frame plate 2 is connected to the upper end of the support foot 4, the lower guide rod 52 runs through the protection plate 3, and the rear end extends out. The rear fixed frame plate 2 is connected to the lower end of the support foot 4, and the upper guide rod 51 is symmetrical to the lower guide rod 52 Parallel arrangement; the middle area of the front fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com