Positive electrode active material of lithium-ion battery, preparation method and application of positive electrode active material

A technology for positive active materials and lithium-ion batteries, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of positive active materials such as sedimentation, sedimentation, and low density of conductive agents, so as to solve the problem of sedimentation, simple preparation process, The effect of excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

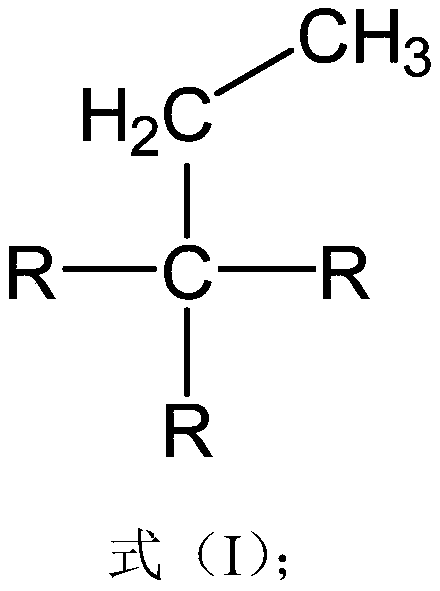

[0048] A kind of preparation method of star polymer comprises the steps:

[0049] (1) be that 80% dodecyl primary amine ethanol solution (containing dodecyl primary amine 0.15mol) and acidic catalyst (85%H 3 PO 4 , 0.50g), warming up to 50 ° C, dropwise adding a mass fraction of 70% trimethylolpropane-three (3- aziridinyl propionate) ethanol solution (which contains trimethylolpropane-three (3 - aziridinyl propionate) 0.05mol), the dropwise addition time is 40min, after the dropwise addition is completed, the temperature is raised to 70°C for 6h;

[0050] (2) Adjust the above reaction solution to weak alkaline (pH=10) with NaOH, add dropwise an 80% aqueous solution of chloroethylsulfonic acid (containing 0.30 mol of sodium 2-chloroethylsulfonate), dropwise The time is 60 minutes, and the reaction is carried out at 70° C. for 16 hours; after the reaction, the insoluble matter is removed, the reaction liquid is concentrated, the product is purified by toluene column chromatogr...

Embodiment 2

[0052] A kind of preparation method of star polymer comprises the steps:

[0053] (1) be that 80% dodecyl primary amine ethanol solution (containing dodecyl primary amine 0.15mol) and acidic catalyst (85%H 3 PO 4 , 0.50g), warming up to 50 ° C, dropwise adding a mass fraction of 70% trimethylolpropane-three (3- aziridinyl propionate) ethanol solution (which contains trimethylolpropane-three (3 - aziridinyl propionate) 0.05mol), the dropwise addition time is 40min, after the dropwise addition is completed, the temperature is raised to 70°C for 6h;

[0054] (2) Adjust the above reaction solution to weak alkaline (pH=10) with NaOH, add dropwise 2-chloroethyl sodium phosphate aqueous solution (containing 0.30 mol of 2-chloroethyl sodium phosphate) with a mass fraction of 80%, dropwise The addition time was 60 minutes, and the reaction was carried out at 70°C for 16 hours; after the reaction, the insoluble matter was removed, the reaction liquid was concentrated, the product was ...

Embodiment 3

[0056] A kind of preparation method of star polymer comprises the steps:

[0057] (1) be that 80% dodecyl primary amine ethanol solution (containing dodecyl primary amine 0.15mol) and acidic catalyst (85%H 3 PO 4 , 0.50g), warming up to 50 ° C, dropwise adding a mass fraction of 70% trimethylolpropane-three (3- aziridinyl propionate) ethanol solution (which contains trimethylolpropane-three (3 - aziridinyl propionate), 0.05mol), the dropwise addition time is 40min, after the dropwise addition is completed, the temperature is raised to 70°C for 6h;

[0058] (2) The above reaction solution was adjusted to weakly alkaline (pH=10) with NaOH, and an aqueous solution of chloroethyl methyl ether (containing 0.30 mol of 2-chloroethyl methyl ether) with a mass fraction of 80% was added dropwise. After 60 minutes, react at 70°C for 16 hours; after the reaction, remove the insoluble matter, concentrate the reaction solution, purify and isolate the product by toluene column chromatograp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com