A duplex stainless steel clad steel plate for seawater desalination and its manufacturing method

A technology of duplex stainless steel and clad steel plate, applied in the field of clad plate, can solve the problem of incompatibility of strength and corrosion resistance, and achieve the effect of high billet assembly efficiency, high mechanical properties, and high intergranular corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

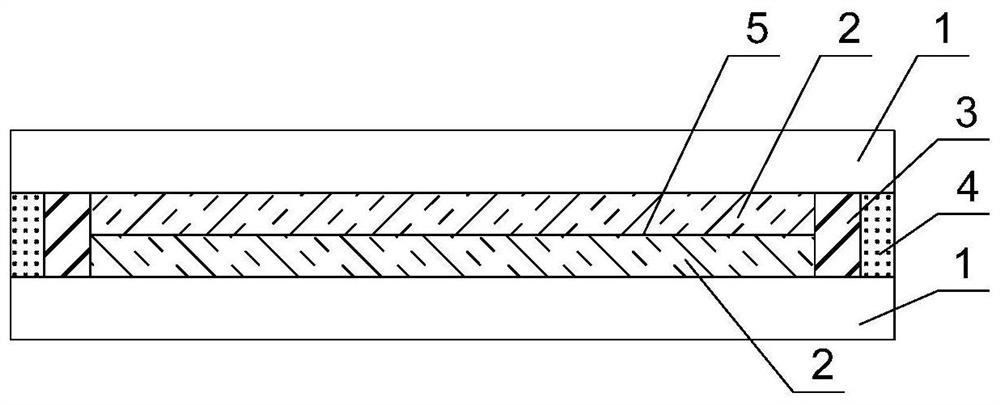

[0063] Embodiment 1 Manufacturing method of duplex stainless steel clad steel plate for seawater desalination. The production process includes billet formation, heating, and rolling. The steel plate specification is: (12+2)×3200×11000mm (thickness×width×length), wherein 1 thickness is 12mm, S32205 duplex stainless steel 2 thickness is 2mm. Specifically:

[0064] (1) Billet assembly: the steel billet smelted according to the chemical composition design is carried out for billet rolling; the thickness of the carbon steel billet is 108mm, and the thickness of the S32205 duplex stainless steel intermediate billet is 18mm, and the surface cleaning of the composite surface is carried out by a milling machine; The duplex stainless steel billet is sent to the drying furnace for drying treatment, the drying temperature is between 280°C and 300°C, and the drying time is 2 hours; two layers of S32205 duplex stainless steel are assembled and welded, and the two layers of S32205 duplex sta...

Embodiment 2

[0068] Embodiment 2 Manufacturing method of duplex stainless steel clad steel plate for seawater desalination. The production process includes billet formation, heating, and rolling. The steel plate specification is: (16+3)×3000×10000mm (thickness×width×length), wherein 1 Thickness is 16mm, S32205 duplex stainless steel 2 Thickness is 3mm. Specifically:

[0069] (1) The steel billet smelted according to the chemical composition design will be opened and rolled; the thickness of the carbon steel billet is 128mm, and the thickness of the S32205 duplex stainless steel middle billet is 24mm. The billet is sent to the drying furnace for drying treatment, the drying temperature is between 250°C and 280°C, and the drying time is 2 hours; two layers of S32205 duplex stainless steel are assembled and welded, and the spacer surface is between the two layers of S32205 duplex stainless steel. Two layers of S32205 duplex stainless steel are assembled with carbon plates up and down, the st...

Embodiment 3

[0073] Embodiment 3 Manufacturing method of duplex stainless steel clad steel plate for seawater desalination. The production process includes billet formation, heating, and rolling. The steel plate specification is: (10+3)×3200×11000mm (thickness×width×length), wherein 1 Thickness is 12mm, S32205 duplex stainless steel 2 Thickness is 3mm. Specifically:

[0074] (1) The steel billets designed and smelted according to the chemical composition will be opened and rolled; the thickness of the carbon steel billet is 90mm, and the thickness of the S32205 duplex stainless steel middle billet is 27mm. The billet is sent to the drying furnace for drying treatment, the drying temperature is between 250°C and 280°C, and the drying time is 2 hours; two layers of S32205 duplex stainless steel are assembled and welded, and the spacer surface is between the two layers of S32205 duplex stainless steel. Two layers of S32205 duplex stainless steel are assembled with carbon plates up and down, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com