Equal-proportion mixed organic silicon sealant for anti-fog vehicle lamp and preparation method thereof

An equal proportion, silicone technology, applied in the direction of adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problems of two-component silicone adhesives that cannot be used, and the ratio fluctuates greatly, so as to improve the mechanical strength And thixotropic, fast curing, low volatile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

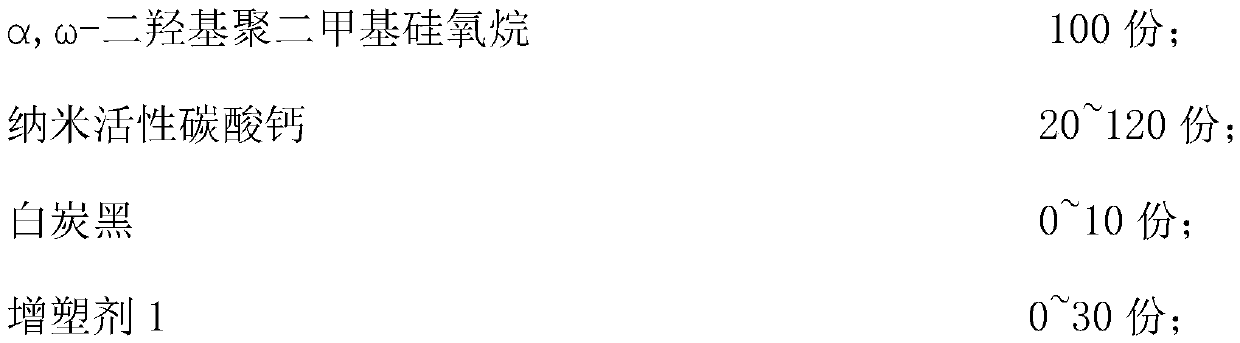

[0038] A component:

[0039] Add 100 parts of 80000mpa.s α, ω-dihydroxypolydimethylsiloxane and 60 parts of nano-active calcium carbonate into the planetary mixer, stir and disperse evenly under vacuum defoaming state, and then discharge for later use.

[0040] B component:

[0041] 100 parts of B-component base material, 5 parts of carbon black (pigment), 20 parts of 100mpa.s dimethylpolydimethylsiloxane, 12 parts of crosslinking agent, γ-aminopropyltrimethoxysilane 2 Parts, 0.05 parts of catalyst dibutyltin diacetate, vacuumize in a high-speed disperser, stir and disperse evenly, and discharge for later use.

[0042] Among them, the crosslinking agent is tetraethyl orthosilicate and dodecyltrimethoxysilane mixed uniformly and heated to 60°C, and under the action of stirring, methanol aqueous solution is added dropwise to undergo hydrolysis and condensation reaction, and then the low molecular weight is removed by distillation under reduced pressure for 2 hours. .

[0043]...

Embodiment 2

[0046] A component:

[0047] Add 100 parts of 20000mpa.s α,ω-dihydroxy polydimethylsiloxane and 80 parts of nano-active calcium carbonate into the planetary mixer, stir and disperse evenly under vacuum defoaming state, and then discharge the materials for later use.

[0048] B component:

[0049] 100 parts of base material of component B, 10 parts of carbon black, 30 parts of dimethylpolydimethylsiloxane of 100mpa.s, 10 parts of crosslinking agent, 3 parts of γ-aminopropyltrimethoxysilane, catalyst 0.05 part of dibutyl tin dilaurate is vacuumized in a high-speed disperser, stirred and dispersed evenly, and then discharged for later use;

[0050] The cross-linking agent is prepared by mixing methyltrimethoxysilane and octyltrimethoxysilane evenly and raising the temperature to 50°C, adding dropwise methanol aqueous solution to undergo hydrolysis and condensation reaction under the action of stirring, and then distilling under reduced pressure for 2 hours to remove the low mole...

Embodiment 3

[0054] A component:

[0055] Add 100 parts of α,ω-dihydroxy polydimethylsiloxane with a viscosity of 20000mpa.s and 100 parts of nano-active calcium carbonate into the planetary mixer, stir and disperse evenly under vacuum defoaming state, and then discharge for later use.

[0056] B component:

[0057] 100 parts of B-component base material, 10 parts of carbon black, 30 parts of methyldimethoxy-terminated polydimethylsiloxane with a viscosity of 20000mpa.s, 3 parts of crosslinking agent, γ-aminopropyl trimethoxy 3 parts of base silane, 0.05 part of catalyst dibutyl tin dilaurate, vacuumize in a high-speed disperser, stir and disperse evenly, and then discharge for standby;

[0058] The cross-linking agent is tetraethyl orthosilicate and octyltrimethoxysilane mixed uniformly and heated to 60°C, and methanol aqueous solution is added dropwise under stirring to undergo hydrolysis and condensation reaction, and then the low molecular weight is removed by distillation under reduc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com