Modified ZnO/PET protective film with high barrier property and preparation method thereof

A high-barrier, protective film technology, applied in the field of polymer composite material synthesis, can solve the problems of decreased mechanical properties, poor barrier performance of PET protective film, uneven mixing of PET composite materials, etc., to achieve uniform distribution, reduce production costs, and combine tight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of described PET modified masterbatch comprises the following concrete steps:

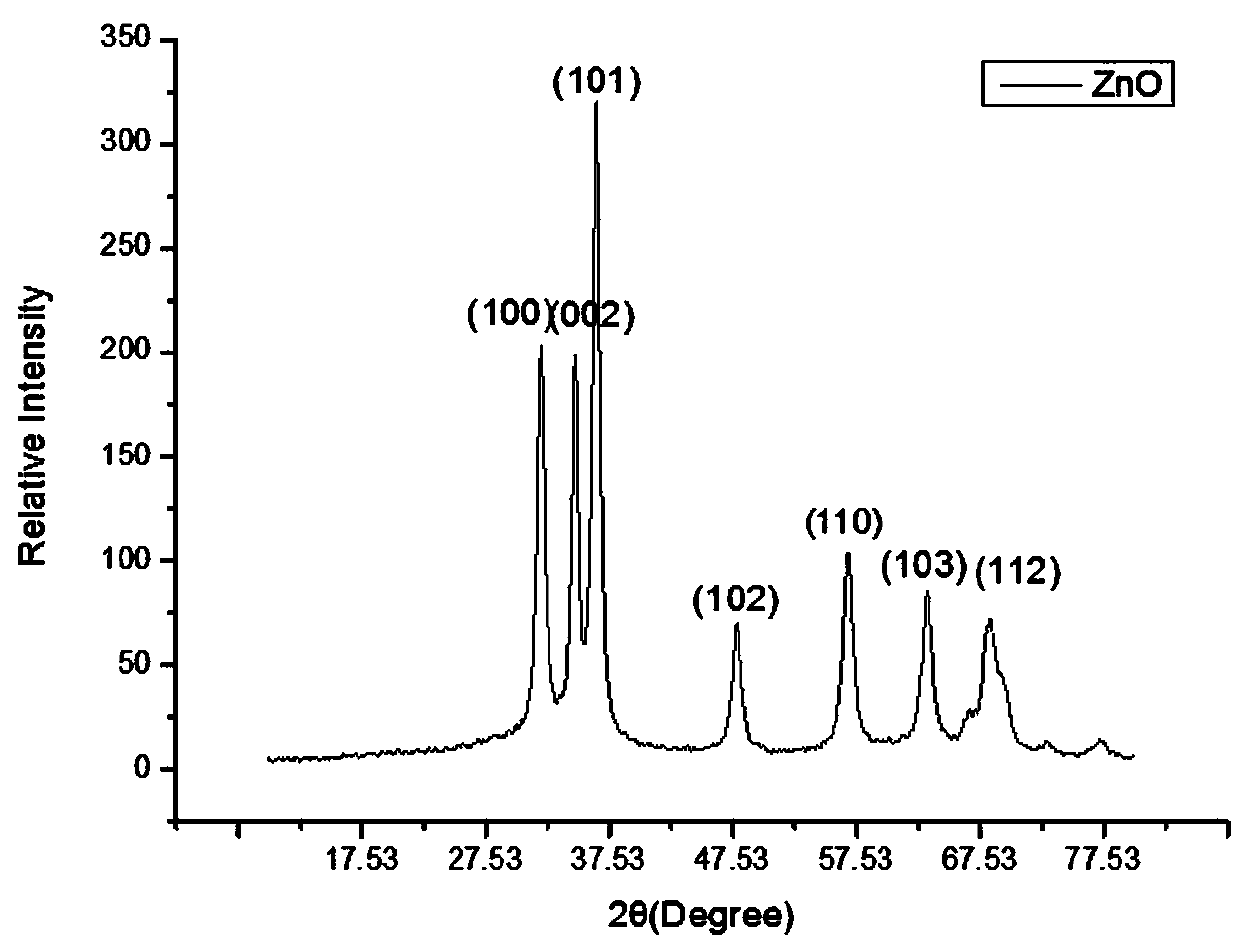

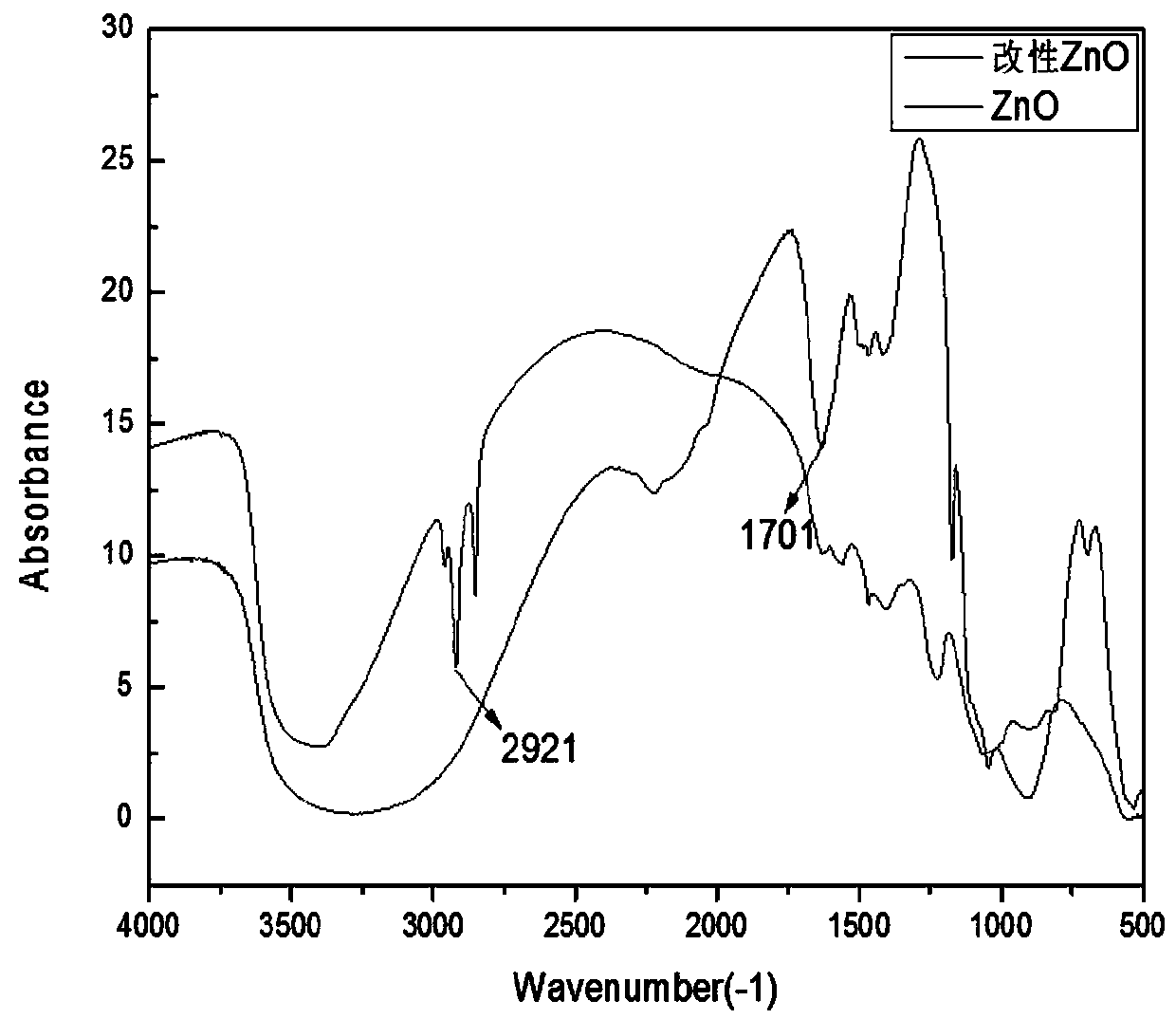

[0027] a) Preparation of modified nano-ZnO: Dissolve 10.0g zinc stearate in 50ml toluene to form a homogeneous solution, slowly add 15ml 4mol / L sulfuric acid solution dropwise to the solution to generate a layered stearic acid / toluene mixture and zinc sulfate solution, the gained solution is extracted and separated to obtain stearic acid / toluene mixed solution and zinc sulfate solution; 7g sodium lignosulfonate is dissolved in 50ml deionized water to form a surfactant solution; the zinc sulfate solution obtained by extraction is stirred Slowly add it dropwise to the surfactant solution, mix well, add 100ml of absolute ethanol, then slowly dropwise add 20ml 2.5M NaOH solution, stir for 30min and mix well, put the mixed solution in a water bath at 80°C and stir for 5h, The obtained product was centrifuged, washed, and dried at 50°C to obtain nano-ZnO; the dried nano-ZnO ...

Embodiment 1

[0031] A kind of raw material of modified nano ZnO / PET protective film with high barrier property comprises by weight parts:

[0032] PET resin: 100 parts;

[0033] PET modified masterbatch: 30 parts.

[0034] The PET resin is polyethylene terephthalate (China Resources Polyester (Changzhou) Co., Ltd., 8863), the molecular weight of the monomer terephthalic acid used in its synthesis is 166.13, and the density is 1.55g / cm 3 ; The molecular weight of ethylene glycol is 62.068, and the density is 1.12 g / cm 3 . The intrinsic viscosity of the PET resin is 0.800~0.840 dl / g, the melting point is greater than or equal to 240°C, and the density is 1.38g / cm 3 , Shore hardness 105~110A.

[0035] A preparation method of modified nano-ZnO / PET protective film with high barrier properties: after mixing PET resin and PET modified masterbatch at a rotation speed of 500r / min according to the raw material components, dry at 150°C 4h, injection molded by an injection machine at a temperatur...

Embodiment 2

[0037] A kind of raw material of modified nano ZnO / PET protective film with high barrier property comprises by weight parts:

[0038] PET resin: 100 parts;

[0039] PET modified masterbatch: 30 parts.

[0040] The PET resin is polyethylene terephthalate, the molecular weight of monomer terephthalic acid used in its synthesis is 166.13, and the density is 1.55g / cm 3 ; The molecular weight of ethylene glycol is 62.068, and the density is 1.12 g / cm 3 . The intrinsic viscosity of the PET resin is 0.800~0.840 dl / g, the melting point is greater than or equal to 240°C, and the density is 1.38 g / cm 3 , Shore hardness 105~110A.

[0041] A preparation method of modified nano-ZnO / PET protective film with high barrier properties: after mixing PET resin and PET modified masterbatch at a speed of 500r / min according to the raw material components, dry at 120°C for 6h, It is injection molded by injection machine with a temperature of 245°C. The mixing conditions of the PET modified mast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com