High-efficiency antibacterial medical polyvinyl chloride elastomer

A technology of polyvinyl chloride and elastomer, which is applied in the field of high-efficiency antibacterial medical polyvinyl chloride elastomer, can solve the problems of unguaranteed aseptic effect, insufficient elasticity, long sterilization cycle, etc., and achieve the reduction of ethylene oxide Harmful to the environment and human body, excellent resilience, and good processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Weigh 100 parts of polyvinyl chloride resin (polymerization degree 2000), 70 parts of plasticizer DOP, 50 parts of elastomer EVA, 6 parts of auxiliary plasticizer ESO, 1 part of high-efficiency antibacterial agent, heat stabilizer (CaSt, ZnSt mixture) 1 parts, 0.3 parts of lubricant oxidized polyethylene.

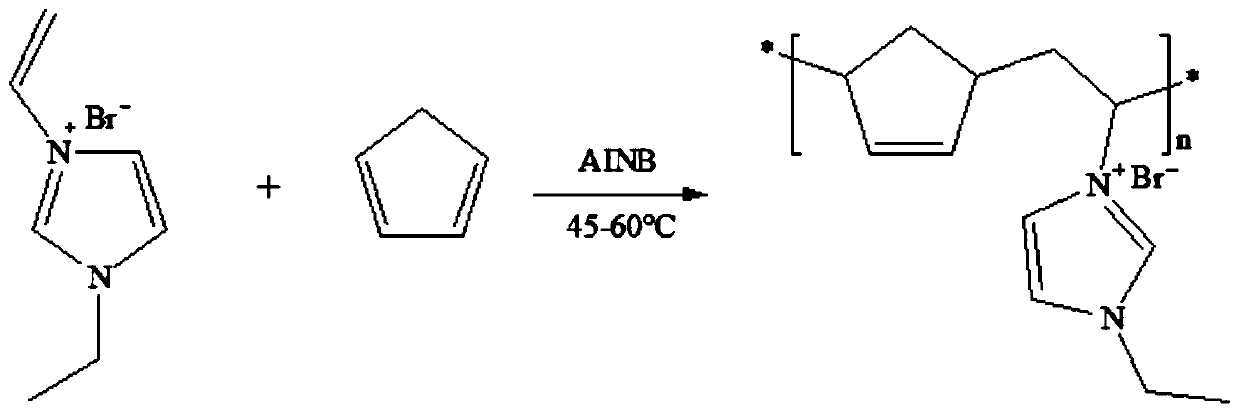

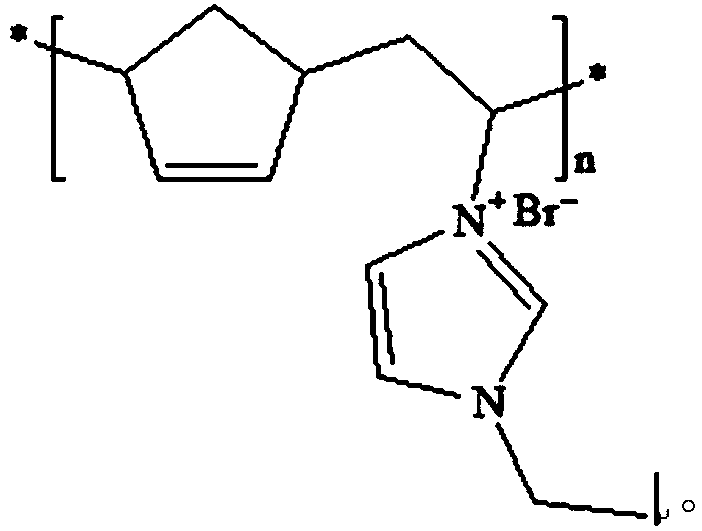

[0042] A kind of preparation method of high-efficiency antibacterial agent, its concrete steps are: take 1-vinyl-3-ethyl imidazolium bromide and cyclopentadiene as raw material, azobisisobutyronitrile (AIBN) as initiator, in reaction The temperature is 45-60°C, the raw materials and the initiator are mixed evenly, and then reacted under nitrogen protection, the reaction time is controlled to be 4-6 hours, so that the conversion rate of the monomer is more than 96%, and the polymer antibacterial agent is prepared. The molar ratio of 1-vinyl-3-ethylimidazolium bromide to cyclopentadiene is 1:1, and the initiator is controlled to be 0.2wt% of the total mass of the two r...

Embodiment 2

[0049] Weigh 100 parts of PVC resin (polymerization degree 2500), 80 parts of plasticizer DOP, 30 parts of elastomer NBR, 8 parts of auxiliary plasticizer ESO, 3 parts of high-efficiency antibacterial agent, 1.5 parts of heat stabilizer (CaSt, ZnSt mixture) , 0.5 parts of lubricant polyamide wax.

[0050] The preparation method is the same as in Example 1.

Embodiment 3

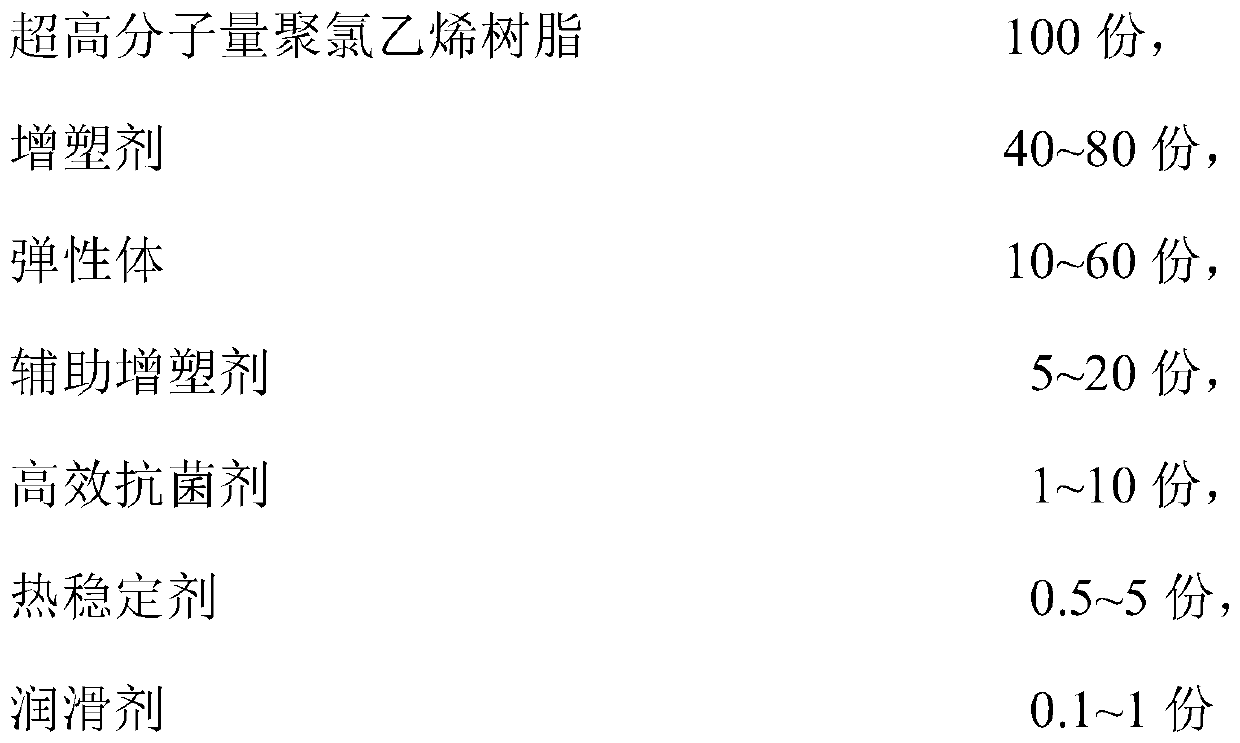

[0060] The application also provides a polyvinyl chloride / polyurethane elastomer medical material, the parts by weight of the raw material components are:

[0061]

[0062] The preparation method of polyvinyl chloride / polyurethane elastomer medical material comprises the steps:

[0063] 1. Premix each component in a kneader at 100°C to 150°C to obtain a premix;

[0064] 2. Add the above-mentioned premixed materials into a two-stage extruder, plasticize, extrude and granulate at 120°C to 180°C to obtain the product.

[0065] Polyvinyl chloride / polyurethane elastomer material has excellent cold resistance, which is tested according to the GB / T 5470-2008 standard. The cold resistance performance is as follows: it can be used for a long time at -50 ° C ~ -60 ° C, and can be used to make blood bags Or other blood product packaging materials and medical materials for other purposes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com