Preparation method of methyl trifluoroethyl carbonate

A technology of methyl trifluoroethyl carbonate and trifluoroethanol, which is applied in the field of electrolyte, can solve the problems of low flash point, explosion, lithium-ion battery fire, etc., achieve low environmental pressure, simple preparation process, and low preparation cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

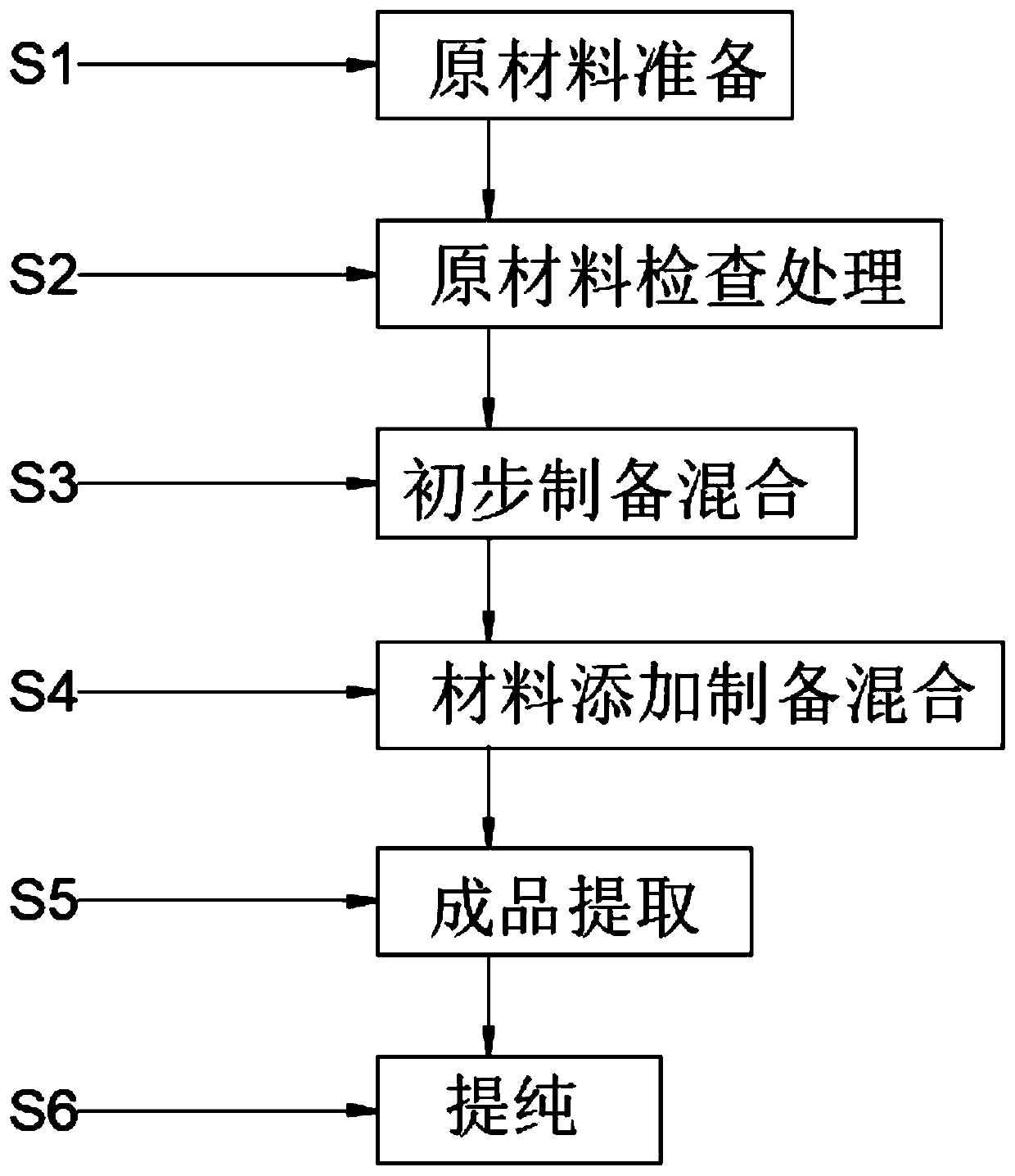

[0027] see figure 1 , the present invention provides following technical scheme:

[0028] A preparation formula of methyl trifluoroethyl carbonate is prepared by mixing the following materials: trifluoroethanol, N'N-carbonyldiimidazole, methanol and dilute hydrochloric acid.

[0029] A preparation method of methyl trifluoroethyl carbonate, comprising the following steps:

[0030] S1. Preparation of raw materials: Raw materials such as trifluoroethanol, N'N-carbonyldiimidazole, methanol and dilute hydrochloric acid are weighed according to the weight required for the proportioning, and then the relevant equipment required for the preparation process is prepared.

[0031] S2. Raw material inspection and treatment: check raw materials such as trifluoroethanol, N'N-carbonyldiimidazole, methanol and dilute hydrochloric acid to avoid other impurities in the raw materials, and then dry these raw materials.

[0032] S3. Preliminary preparation and mixing: In the anhydrous atmosphere...

Embodiment 2

[0044] see figure 1 , the present invention provides following technical scheme:

[0045] A preparation formula of methyl trifluoroethyl carbonate is prepared by mixing the following materials: trifluoroethanol, N'N-carbonyldiimidazole, methanol and dilute hydrochloric acid.

[0046] A preparation method of methyl trifluoroethyl carbonate, comprising the following steps:

[0047] S1. Preparation of raw materials: Raw materials such as trifluoroethanol, N'N-carbonyldiimidazole, methanol and dilute hydrochloric acid are weighed according to the weight required for the proportioning, and then the relevant equipment required for the preparation process is prepared.

[0048] S2. Raw material inspection and treatment: check raw materials such as trifluoroethanol, N'N-carbonyldiimidazole, methanol and dilute hydrochloric acid to avoid other impurities in the raw materials, and then dry these raw materials.

[0049]S3. Preliminary preparation and mixing: In the anhydrous atmosphere ...

Embodiment 3

[0061] see figure 1 , the present invention provides following technical scheme:

[0062] A preparation formula of methyl trifluoroethyl carbonate is prepared by mixing the following materials: trifluoroethanol, N'N-carbonyldiimidazole, methanol and dilute hydrochloric acid.

[0063] A preparation method of methyl trifluoroethyl carbonate, comprising the following steps:

[0064] S1. Preparation of raw materials: Raw materials such as trifluoroethanol, N'N-carbonyldiimidazole, methanol and dilute hydrochloric acid are weighed according to the weight required for the proportioning, and then the relevant equipment required for the preparation process is prepared.

[0065] S2. Raw material inspection and treatment: check raw materials such as trifluoroethanol, N'N-carbonyldiimidazole, methanol and dilute hydrochloric acid to avoid other impurities in the raw materials, and then dry these raw materials.

[0066] S3. Preliminary preparation and mixing: In the anhydrous atmosphere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com