Alloy type golden cold firework composition and preparation method thereof

An alloy-type, cold-smoke flower technology, which is applied in the direction of explosives, nitrated acyclic/alicyclic/heterocyclic amine explosive compositions, etc., can solve the problem of limiting the application diversity of cold-smoke flower agents, weak preparation of cold-smoke flower agents, and affecting human health, etc. problems, achieving significant economic and social benefits, fewer steps, and no discharge of three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

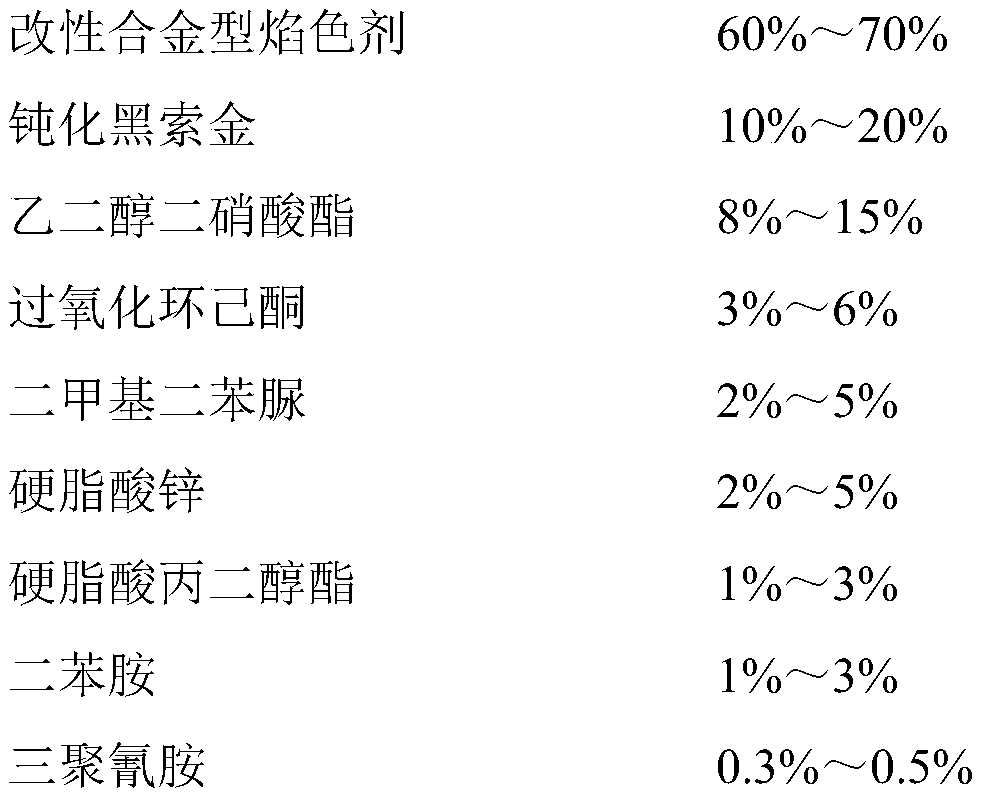

[0036] An alloy type golden cold smoke flower medicament, the mass percentage of each component is as follows:

[0037]

[0038] Add 600g of passivated RDX to 6kg of petroleum ether, stir the above mixed solution at a rate of 100rpm, add 368g of ethylene glycol dinitrate and 132g of dimethyl diphenyl urea under stirring, and stir for 35 minutes After making solution A;

[0039] Add 100g of zinc stearate to 860g of ethylene glycol, stir the above mixed solution at a rate of 100rpm, raise the temperature to 65°C at the same time, add 64g of propylene glycol stearate, 60g of diphenylamine and 16g of melamine was stirred to make solution B after 35 minutes;

[0040] Stir 630 g of absolute ethanol at a rate of 100 rpm at 5°C, add 180 g of cyclohexanone peroxide powder to the absolute ethanol during the stirring process, and ultrasonically disperse for 70 minutes to obtain solution C;

[0041] Use a steel brush to remove the oxide layer on the surface of the zirconium ingot, pl...

Embodiment 2

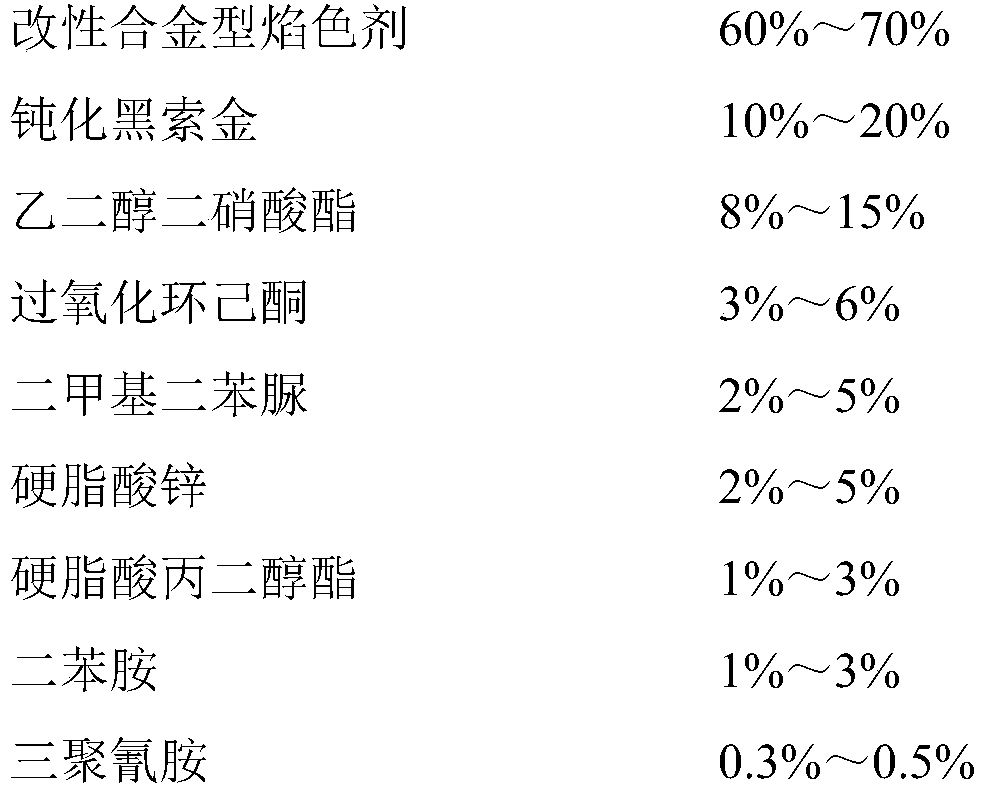

[0050] An alloy type golden cold smoke flower medicament, the mass percentage of each component is as follows:

[0051]

[0052] Add 1 kg of passivated RDX to 8 kg of petroleum ether, stir the above mixed solution at a rate of 100 rpm, add 0.9 kg of ethylene glycol dinitrate and 0.25 kg of dimethyl diphenylurea respectively under stirring, and stir Solution A was obtained after 45 minutes;

[0053] Add 0.2kg of zinc stearate to 1.5kg of ethylene glycol, stir the above mixed solution at a rate of 100rpm, raise the temperature to 60°C at the same time, add 0.15kg of propylene glycol stearate, 0.15 kg diphenylamine and 0.05kg melamine, after stirring for 45 minutes, solution B was obtained;

[0054] Stir 1 kg of absolute ethanol at a rate of 100 rpm at 5°C, add 0.3 kg of cyclohexanone peroxide powder to the absolute ethanol during the stirring process, and ultrasonically disperse for 70 minutes to obtain solution C;

[0055] Use a steel brush to remove the oxide layer on the...

Embodiment 3

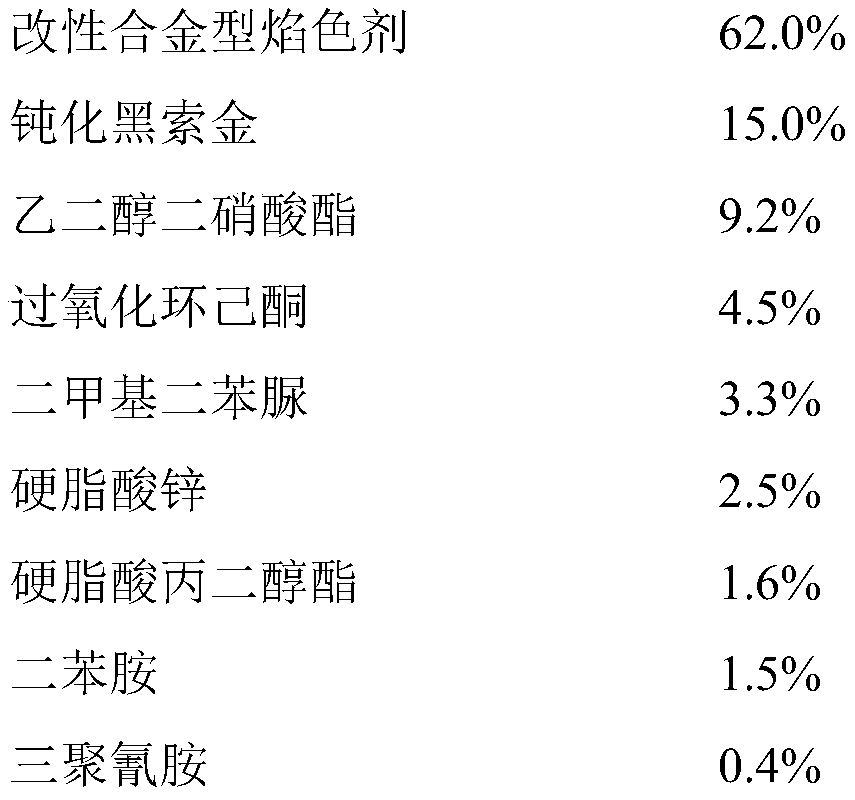

[0064] An alloy type golden cold smoke flower medicament, the mass percentage of each component is as follows:

[0065]

[0066] Add 15kg of passivated RDX to 250kg of petroleum ether, stir the above mixed solution at a rate of 80rpm, add 10kg of ethylene glycol dinitrate and 2kg of dimethyl diphenyl urea under stirring, and stir for 50 minutes After making solution A;

[0067] Add 2kg of zinc stearate to 10kg of ethylene glycol, stir the above mixed solution at a rate of 80rpm, raise the temperature to 65°C at the same time, add 1kg of propylene glycol stearate, 1kg of diphenylamine and 0.5kg melamine, after stirring for 50 minutes, solution B was obtained;

[0068] Stir 17 kg of absolute ethanol at a rate of 100 rpm at 5°C, add 5.5 kg of cyclohexanone peroxide powder to the absolute ethanol during the stirring process, and ultrasonically disperse for 70 minutes to obtain solution C;

[0069] Use a steel brush to remove the oxide layer on the surface of the zirconium ing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ignite | aaaaa | aaaaa |

| Ignite | aaaaa | aaaaa |

| Ignite | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com