Combined degradation treatment method of high-concentration high-polymerization-degree polyvinyl alcohol wastewater

A polyvinyl alcohol and treatment method technology, applied in water/sewage treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of iron sludge, low treatment process, lack of cost, etc., To achieve the effect of reducing cost, efficient degradation and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

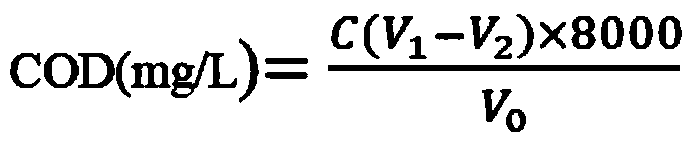

Embodiment 1

[0048] A combined degradation treatment method for high-concentration and high-polymerization degree polyvinyl alcohol wastewater, comprising the following steps:

[0049] (1) Add 0.92L of sodium hypochlorite solution (commercially available analytically pure sodium hypochlorite solution) to 1L of polyvinyl alcohol wastewater with a degree of polymerization of 2400 and a concentration of 15wt.% and carry out pre-oxidation degradation by stirring to obtain solution B after pre-oxidation treatment ; Stirring process parameters are: mechanical stirring speed 375r / min, stirring reaction time 2h, reaction temperature 40°C;

[0050] (2) the solution B of step (1) gained adopts the sulfuric acid solution of 50wt.% to adjust the pH value to 3, then adding 5.12L mass concentration is 30% hydrogen peroxide solution and 351.57g copper-cobalt composite-activated carbon carrier type catalyst , carry out catalytic oxidation degradation by stirring reaction, the stirring reaction time is 40m...

Embodiment 2

[0053] A combined degradation treatment method for high-concentration and high-polymerization degree polyvinyl alcohol wastewater, comprising the following steps:

[0054] (1) Add 0.92L of sodium hypochlorite solution (commercially available analytically pure sodium hypochlorite solution) to 1L of polyvinyl alcohol wastewater with a degree of polymerization of 2600 and a concentration of 15wt.% and carry out pre-oxidative degradation by stirring reaction to obtain solution B after pre-oxidative treatment ; Stirring process parameters are: mechanical stirring speed 600r / min, stirring reaction time 2h, reaction temperature 90°C;

[0055](2) the solution B of step (1) gained adopts the sulfuric acid solution of 50wt.% to adjust the pH value to 3, then adding 5.12L mass concentration is 50% hydrogen peroxide solution and 527.35g copper-activated carbon carrier type catalyst, by stirring The reaction is carried out by catalytic oxidation degradation, the stirring reaction time is 6...

Embodiment 3

[0058] A combined degradation treatment method for high-concentration and high-polymerization degree polyvinyl alcohol wastewater, comprising the following steps:

[0059] (1) Add 0.58L of sodium hypochlorite solution (commercially available analytically pure sodium hypochlorite solution) to 1L of polyvinyl alcohol wastewater with a degree of polymerization of 500 and a concentration of 30wt.%, and carry out pre-oxidation degradation by stirring reaction to obtain solution B after pre-oxidation treatment ; Stirring process parameters are: mechanical stirring speed 300r / min, stirring reaction time 1h, reaction temperature 40°C;

[0060] (2) the solution B of step (1) gained adopts the sulfuric acid solution of 50wt.% to adjust the pH value to 3, then adding 1.74L mass concentration is 30% hydrogen peroxide solution and 175.78g cobalt-activated carbon carrier type catalyst, by stirring The reaction is carried out by catalytic oxidation degradation, the stirring reaction time is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com