Catalyst for preparing H2 through conversion of methanol steam and application thereof

A technology of water vapor and catalyst, which is applied in the field of hydrogen (H2) preparation, can solve the problems of medium and low temperature conversion load increase, low space-time ratio, and high CO content, and achieve the effects of load reduction, capacity increase, and CO content reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

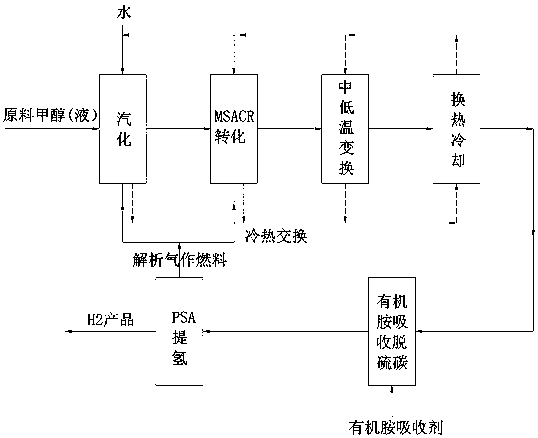

[0020] Such as figure 1 As shown, a catalyst for preparing H2 by converting methanol to water vapor and its application, the precursor prepared by the copper-cobalt bimetallic catalyst is a mixed solution of copper nitrate (Cu(NO3)2) and cobalt nitrate (Co(NO3)2). The catalyst precursor is a mixed solution of lanthanum nitrate (La(NO3)3) and potassium nitrate (KNO3), and the carrier is a mixture of pretreated multilayer carbon nanotubes (CNTs) and aluminum oxide (Al2O3). Melt-roasting method, to obtain active component copper 50~55% (w / w, hereinafter similar), cobalt 10~15%, catalyst promoter component lanthanum 1~3%, promoter potassium 3~5% , and the rest of the mixed carrier carbon nanotubes and aluminum oxide, and the aerobic catalytic reaction of methanol-steam conversion to produce hydrogen (H2) by methanol-steam conversion as follows:

[0021] (1) The raw material is industrial methanol (liquid), which is mixed with water vapor to form methanol vapor, which is compresse...

Embodiment 2

[0027] The pretreatment of the multilayer carbon nanotube CNTs described in Example 1 is to add about 1 to 2 g of commercially sold CNTs carriers with a specification of 10 nm into a total volume of about 230 to 260 mL of nitric acid with a mass concentration of 30% and about 70% In the mixed solution of nitric acid with mass concentration, heat to 110~120°C, stir evenly, and azeotropically reflux at 110~120°C for 6~8 hours, cool to ambient temperature, vacuum filter, wash with deionized water for two After three times until neutral, the resulting filter cake is dried at 120°C for 1-2 hours, ground into 10-20nm powder, mixed with 1-1.5g of activated alumina (Al2O3) powder, under nitrogen flow and 630-660°C After calcination and cooling, a mixed carrier of CNTs and Al2O3 is formed, which is used to support active components Cu, Co, cocatalyst La, and promoter K.

Embodiment 3

[0029] On the basis of Examples 1 and 2, the alcohol heat-roasting method is used to prepare the catalyst for the conversion of methanol and water vapor to prepare H2, and 2~4g of pretreated multilayer carbon nanotubes (CNTs) and activated alumina (Al2O3) are mixed with the carrier, Add it into about 50~70mL absolute ethanol solution, after heating to 30~50℃ and stirring to form a slurry, add a copper-cobalt bimetallic catalyst with a total volume of about 50~100mL to prepare the precursor as copper nitrate (Cu(NO3 )2) and cobalt nitrate (Co(NO3)3) mixed solution, the cocatalyst precursor is a mixed solution of lanthanum nitrate (La(NO3)3) and potassium nitrate (KNO3), and ethanol solution, stir and mix evenly, and then add About 10~30mL of ammonia water, adjust the pH of the mixed solution until it is greater than 10, then heat and stir to form a slurry again, and perform ultrasonication on the slurry for 0.5~1h and dry at 100~130°C for 2~4 hours, then Grind it into powder, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com