Dehydration composition, preparation method and applications thereof

A technology of composition and chelating agent, which is applied in the field of dehydration composition and its preparation, and can solve problems such as corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

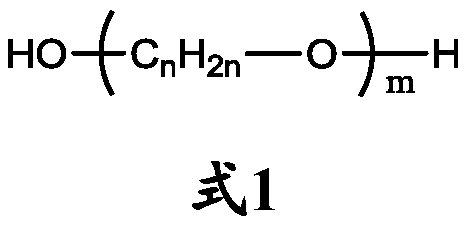

Method used

Image

Examples

preparation example Construction

[0051] The preparation method of the present invention will be further described in detail in conjunction with specific examples below. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of protection intended by the present invention.

[0052] The experimental methods used in the following examples are conventional methods unless otherwise specified; the reagents and materials used in the following examples can be obtained from commercial sources unless otherwise specified.

Embodiment 1 and comparative example 1

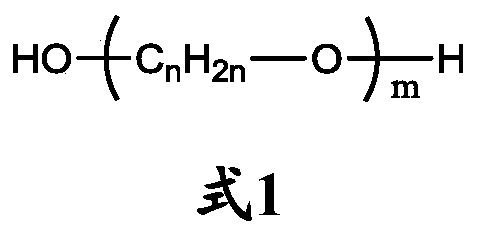

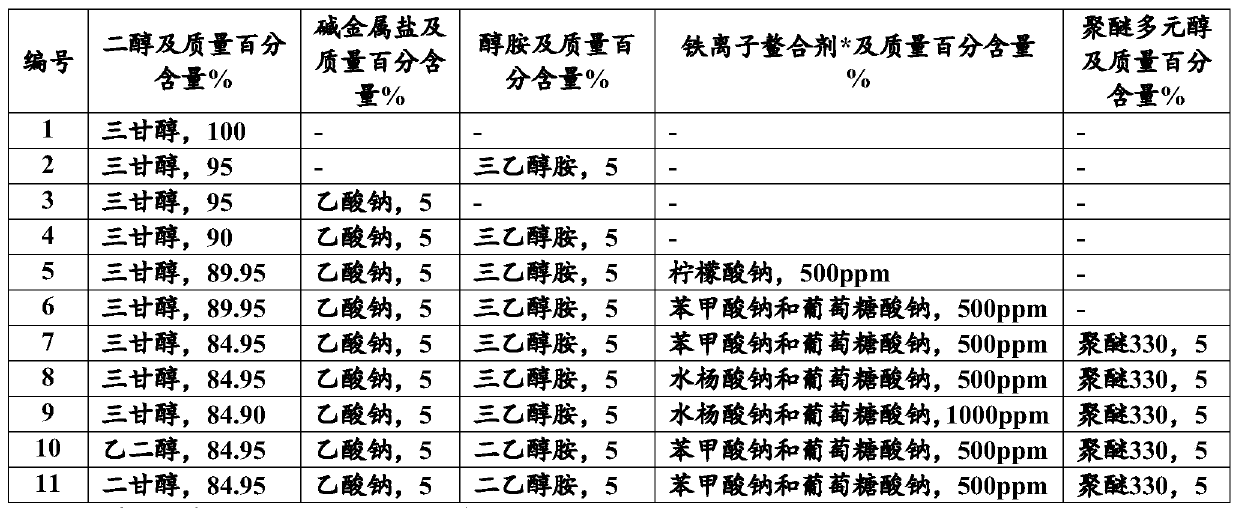

[0054] By each component shown in following table 1, prepare dehydration composition, will test its dehydration ability by the method for test example 1, and test the dehydration composition that needs regeneration by the test method of test example 2 to iron specimen The corrosion conditions are shown in Table 2.

[0055] Polyether polyol polyether 330 is commercial product HSH330 (from Jiangsu Haian Petrochemical Plant).

[0056] Table 1

[0057]

[0058] *: multi-component chelating agent mixture, the weight ratio of each component is 1

Embodiment 2

[0077] Water-containing methyl chloride (among them, containing 0.2% water, 95% methyl chloride, and 4.8% isobutylene) 529.2kg / hr, pressure 430kPa, temperature 22°C, enters the absorption tower from the bottom of the tower, and 50kg is added to the top of the absorption tower with 5 trays The dehydration composition with / hr number 7 has a pressure of 430 kPa and a temperature of 22°C. 484.6 kg / hr of methyl chloride containing 60 ppm of water is discharged from the top of the absorption tower.

[0078] The dehydration composition to be regenerated is discharged from the bottom of the absorption tower at 94.6kg / hr, containing 1.1% water and 42% methyl chloride. The dehydration composition containing water and methyl chloride discharged from the bottom of the tower is regenerated through flash dechlorination, rectification and dehydration to reduce the moisture in the dehydration composition to below 0.2%, and the regenerated dehydration composition is returned to the dehydratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com