Processing aid containing rice bran wax, and preparation method thereof

A technology of processing aid and rice bran wax, which is applied in the field of processing aid containing rice bran wax and its preparation, can solve problems such as limited application, and achieve the effects of improving processing performance, improving antistatic performance and improving heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

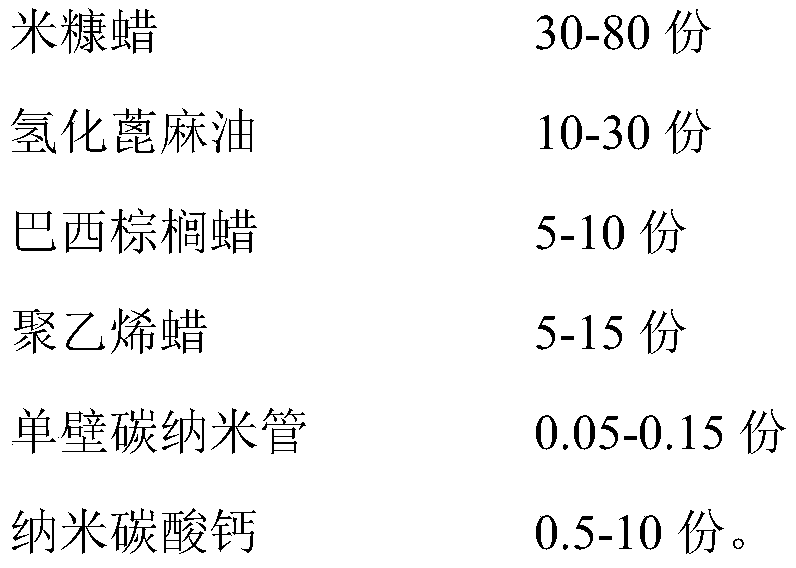

[0035] A processing aid containing rice bran wax, comprising the following components in parts by mass:

[0036]

[0037]

[0038] Wherein, described rice bran wax is made through following pretreatment:

[0039] Deoiling: put the untreated rice bran wax into a reaction kettle, soak it in ethyl acetate of 100wt% rice bran wax for 4 hours, then remove the ethyl acetate solution at the bottom, and cool to obtain the deoiled rice bran wax;

[0040] Oxidation: heat the above-mentioned deoiled rice bran wax to 90°C, melt and cool to obtain a solid, and slice the solid, then slice the slice, and use 100wt% rice bran wax and dilute sulfuric acid with a concentration of 40wt% Mix and heat to 90°C, then add 200wt% rice bran wax with a concentration of 30wt% red alum sodium solution, stir for 1 hour, cool down, after standing still, the mixed solution is separated, and the upper layer is taken;

[0041] Pickling and water washing: heat the above upper layer liquid to 90°C, add 10...

Embodiment 2

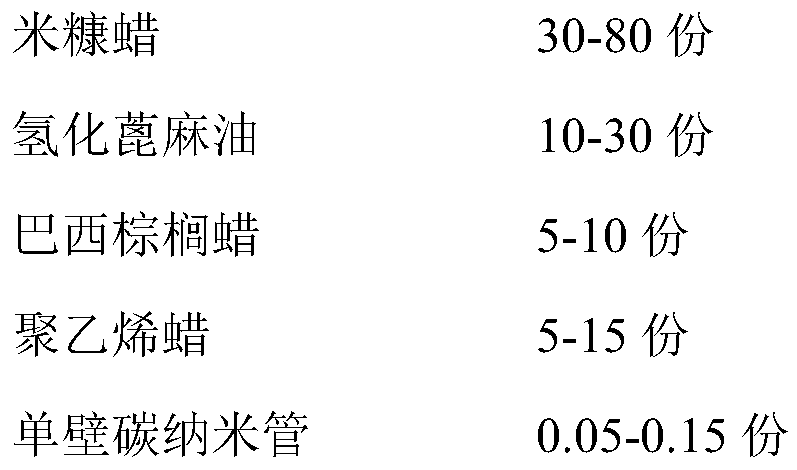

[0052] A processing aid containing rice bran wax, comprising the following components in parts by mass:

[0053]

[0054]

[0055] Wherein, described rice bran wax is made through following pretreatment:

[0056] Deoiling: put the untreated rice bran wax into the reaction kettle, soak it with 300wt% ethyl acetate of rice bran wax for 6 hours, then remove the ethyl acetate solution at the bottom, and cool to obtain the deoiled rice bran wax;

[0057] Oxidation: heat the above-mentioned deoiled rice bran wax to 100°C, melt and cool to obtain a solid, and slice the solid, then slice the slice, and use 400wt% rice bran wax and dilute sulfuric acid with a concentration of 60wt% Mix and heat to 100°C, then add sodium red alum solution with an amount of 400wt% rice bran wax and a concentration of 50wt%, stir for 2 hours and then cool down, after standing still, the mixed solution is layered, and the upper layer liquid is taken;

[0058] Pickling and water washing: heating the ...

Embodiment 3

[0069] A processing aid containing rice bran wax, comprising the following components in parts by mass:

[0070]

[0071] Wherein, described rice bran wax is made through following pretreatment:

[0072] Deoiling: put the untreated rice bran wax into a reaction kettle, soak it in 200wt% ethyl acetate of rice bran wax for 5 hours, then remove the ethyl acetate solution at the bottom, and cool to obtain the deoiled rice bran wax;

[0073] Oxidation: heat the above-mentioned deoiled rice bran wax to 95°C, melt and cool to obtain a solid, and slice the solid, then slice the slice, and use 300wt% rice bran wax and dilute sulfuric acid with a concentration of 50wt% Mix and heat to 95°C, then add 300wt% rice bran wax and a 40wt% concentration of red alum sodium solution, stir for 1.5 hours and then cool, after standing still, the mixed solution is layered, and the upper layer is taken;

[0074] Pickling and water washing: heat the above upper layer liquid to 95°C, add 200wt% rice...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com