Preparation method of tuna anserine

A technology of tuna and anserine, applied in the field of protein peptides, can solve the problems of wasting resources, not being environmentally friendly, and low efficiency of anserine, and achieve the effect of improving utilization rate, improving stability, and facilitating subsequent processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

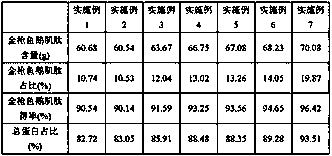

Embodiment 1

[0029] A preparation method for tuna anserine, comprising the steps of:

[0030] S1. Clean the tuna fish body, and remove the head, tail and viscera of the tuna fish.

[0031] S2. Clean the inside of the fish body, collect the cleaning solution, and filter it with a 300-mesh screen to obtain a filtrate.

[0032] S3. Crush the cleaned tuna body in step S2 and mix it with the filtrate obtained in step S2 to obtain a tuna slurry, which is then spray-dried to obtain 1 kg of crude dry powder.

[0033] S4. Mix 1kg of crude dry powder with 8kg of choline chloride deep eutectic solvent, stir at 50°C at 500rpm for 4h, cool to room temperature, then centrifuge at 3000rpm for 30min to obtain the first precipitate and collect it Serum. Wherein, the preparation of the choline chloride deep eutectic solvent comprises the steps of: mixing choline chloride and acetic acid in a molar ratio of 1:5 and stirring at 500 rpm for 3 hours at 60° C. to form a uniform transparent liquid at room tempe...

Embodiment 2

[0037] A preparation method for tuna anserine, comprising the steps of:

[0038] S1. Clean the tuna fish body, and remove the head, tail and viscera of the tuna fish.

[0039] S2. Clean the inside of the fish body, collect the cleaning solution, and filter it with a 300-mesh screen to obtain a filtrate.

[0040] S3. Crush the cleaned tuna body in step S2 and mix it with the filtrate obtained in step S2 to obtain a tuna slurry, which is then spray-dried to obtain 1 kg of crude dry powder.

[0041] S4. Mix 1kg of crude dry powder with 8kg of choline chloride deep eutectic solvent, stir at 50°C at 500rpm for 4h, cool to room temperature, then centrifuge at 3000rpm for 30min to obtain the first precipitate and collect it Serum. Wherein the preparation of the choline chloride deep eutectic solvent comprises the following steps: mixing choline chloride and lactic acid in a molar ratio of 1:5 and stirring at 500 rpm for 3 hours at 60°C to form a uniform transparent liquid, cooling ...

Embodiment 3

[0045] A preparation method for tuna anserine, comprising the steps of:

[0046] S1. Clean the tuna fish body, and remove the head, tail and viscera of the tuna fish.

[0047] S2. Clean the inside of the fish body, collect the cleaning solution, and filter it with a 300-mesh screen to obtain a filtrate.

[0048] S3. Crush the cleaned tuna body in step S2 and mix it with the filtrate obtained in step S2 to obtain a tuna slurry, which is then spray-dried to obtain 1 kg of crude dry powder.

[0049] S4. Mix 1kg of crude dry powder with 8kg of choline chloride deep eutectic solvent, stir at 50°C at 500rpm for 4h, cool to room temperature, then centrifuge at 3000rpm for 30min to obtain the first precipitate and collect it Serum. Wherein the preparation of the choline chloride deep eutectic solvent comprises the steps of: mixing choline chloride and glycerol in a molar ratio of 1:5 and stirring at 500 rpm for 3 hours at 60°C to form a uniform transparent liquid, cooling at room te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com