Preparation method of forsterite-based foamed ceramic spherical shell for civil air defense engineering

An olivine-based and foamed ceramic technology is applied in the field of foamed ceramic spherical shells, which can solve the problems of low density and high strength of the foamed ceramic spherical shells, and achieve a controllable mechanical property at room temperature, simple operation, and controllable pore size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Step 1. Use 67~75wt% forsterite powder, 8~15wt% sericite powder, 8~13wt% silicon micropowder as raw materials, add 10~15wt% binder, 10~15wt% water and 8 ~15wt% pore-forming agent, mixed evenly to obtain mud;

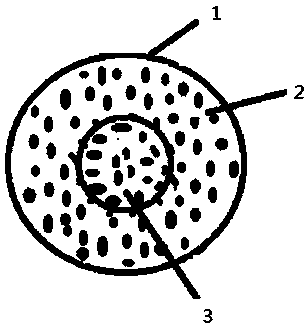

[0032] Step 2: Fill the mud into a hemispherical shell mold with an outer diameter of 6-10 cm and an inner diameter of 3-5 cm, and press it at 5-7 MPa to form a hemispherical shell green body 1, and the middle part of the hemispherical shell green body 1 is a hollow hemisphere 3 , the cross-section of the hemispherical shell green body 1 is an annular structure 2;

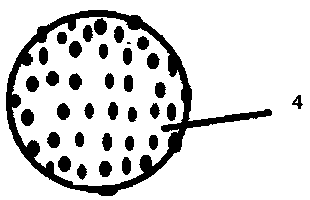

[0033] Under the same pressure, the edges of the hemispherical shells are butted together to form a hollow sphere 4, and demolded. Curing at 25°C for 2-3 hours, and then drying at 60-80°C for 6-12 hours, to obtain the forsterite-based foam ceramic spherical shell body;

[0034] Step 3: Place the forsterite-based foam ceramic spherical shell body in an air atmosphere, raise the temperature to 800-900°...

Embodiment 2

[0037] A forsterite-based foam ceramic spherical shell used in civil defense projects and a preparation method thereof. The present embodiment except step 3, all the other are the same as embodiment 1:

[0038] Step 3. Place the forsterite-based foam ceramic spherical shell body in an air atmosphere, raise the temperature to 900-1000°C at 1-3°C / min and keep it warm for 1-2h, and cool to room temperature to obtain the forsterite-based Foam ceramic spherical shell.

[0039] The pore-forming agent is starch; the binding agent is water glass. The bulk density of the obtained forsterite-based ceramic foam spherical shell matrix material is 1.2~1.7g / cm 3 , The normal temperature compressive strength is 10~15MPa.

Embodiment 3

[0041] Step 1. Use 75~80wt% forsterite powder, 8~15wt% sericite powder, 5~8wt% silicon micropowder as raw materials, add 10~15wt% binder, 15~20wt% water and 8 ~15wt% pore-forming agent, mixed evenly to obtain mud;

[0042] Step 2. Fill the mud into a hemispherical shell mold with an outer diameter of 6-10cm and an inner diameter of 3-5cm, press it at 7-8Mpa to form a hemispherical shell green body, and join the edges of the hemispherical shell under the same pressure to form a mold. A hollow sphere, unmoulded. Curing at 25°C for 3-4 hours, and then drying at 80-100°C for 6-12 hours, to obtain the forsterite-based foam ceramic spherical shell body;

[0043] Step 3: Place the forsterite-based foam ceramic spherical shell body in an air atmosphere, raise the temperature to 800-900°C at 3-7°C / min and keep it warm for 1-2h, and cool to room temperature to obtain the forsterite-based Foam ceramic spherical shell.

[0044] The pore-forming agent is carbon powder; the binding agent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com