Resourceful treatment method of high-concentration phenol-containing wastewater

A treatment method and technology for phenolic wastewater, applied in water/sewage treatment, chemical instruments and methods, adsorbed water/sewage treatment, etc., can solve the problems of secondary pollution, high energy consumption, unstable effluent effect, etc., and achieve effluent indicators Stable, high-yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

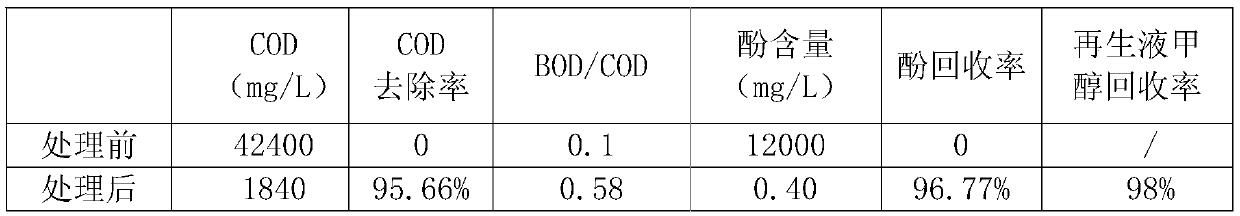

Embodiment 1

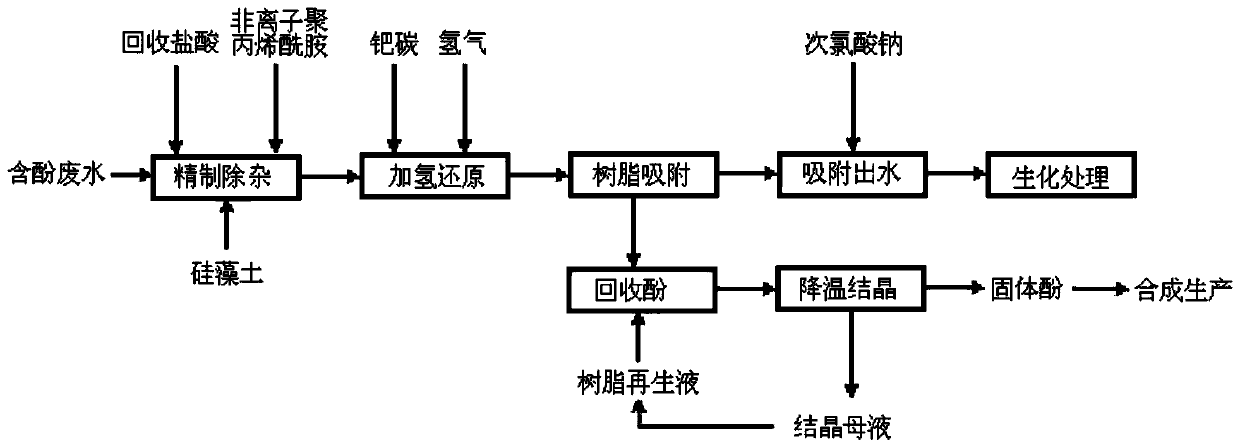

[0034] Using a resource-based treatment method for high-concentration phenol-containing wastewater to treat phenol-containing wastewater from a pesticide factory, the treatment process is as follows figure 1 shown, including the following steps:

[0035] Step 1, refining and impurity removal: adjust the pH of 8 tons of waste water to 3 with the reclaimed hydrochloric acid of mass concentration 30%, the system separates out a large amount of water-insoluble solids, add the nonionic polyacrylamide of 80kg (the mass concentration of nonionic polyacrylamide 2‰), 40kg of diatomite powder with a fineness of 300 mesh, flocculated and adsorbed for 1 hour and then filtered, the filtered water sample changed from red and black turbid to deep yellow and transparent;

[0036] Step 2, hydrogenation reduction: add 6.4kg of 5% palladium-carbon catalyst to the filtrate in step 1, stir and heat up to 40°C, feed hydrogen into the system at a rate of 5L / min, keep the hydrogen flowing for 2 hours...

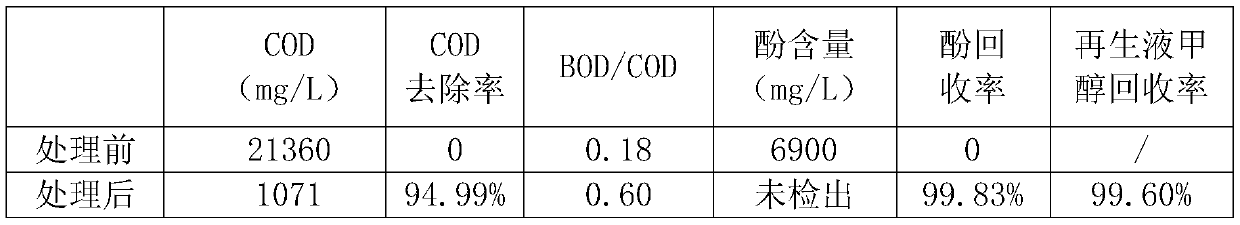

Embodiment 2

[0047] Using a resource-based treatment method for high-concentration phenol-containing wastewater to treat phenol-containing wastewater from a pesticide factory, the treatment process is as follows figure 1 shown, including the following steps:

[0048] Step 1, refining and removing impurities, the difference from Example 1 is that the flocculation and adsorption time is changed from 1 hour to 10 hours, and the filtered water sample changes from red and black turbid to dark yellow and transparent;

[0049] Step 2, hydrogenation reduction: add 64kg5% palladium-carbon catalyst to the filtrate in step 1, stir and heat up to 120°C, feed hydrogen into the system at a rate of 20L / min, keep the hydrogen flowing for 9 hours, and remove the waste water P-benzoquinone is reduced to phenol, and the system changes from dark yellow transparent solution to light yellow to colorless solution;

[0050] Step 3, resin adsorption phenol:

[0051] (3-1) Macroporous adsorption resin pretreatmen...

Embodiment 3

[0060] Using a resource-based treatment method for high-concentration phenol-containing wastewater to treat phenol-containing wastewater from a pesticide factory, the treatment process is as follows figure 1 shown, including the following steps:

[0061] Step 1, refining and impurity removal: adjust the pH of 8 tons of waste water to 3 with reclaimed hydrochloric acid with a mass concentration of 30%, and a large amount of water-insoluble solids are separated out in the system, and nonionic polyacrylamide (nonionic polyacrylamide) of waste water quality 80kg is added The mass concentration is 2‰), and the fineness of 40kg of waste water is 300 mesh diatomite powder, which is filtered after 4 hours of flocculation and adsorption. After filtration, the water sample changes from red and black turbidity to dark yellow and transparent;

[0062] Step 2, hydrogenation reduction: add 64kg of 5% palladium-carbon catalyst to the filtrate in step 1, stir and heat up to 70°C, feed hydroge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com