Adsorption/catalysis material for waste gas treatment and preparation method thereof

A technology for waste gas treatment and catalytic materials, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc. It can solve the problems of easy peeling off of molecular sieve active coating, low carrier specific surface area, and molecular sieve active coating loading capacity. Low-level problems, to achieve the effect of good catalytic reduction ability, high specific surface area, and good exhaust gas treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

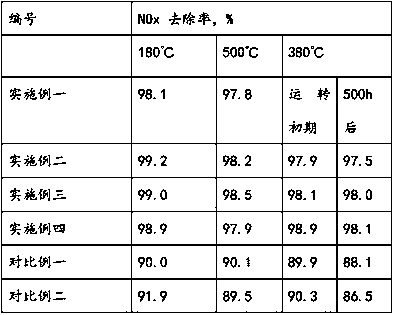

Examples

preparation example Construction

[0033] The preparation method of the adsorption / catalysis material for exhaust gas treatment according to the present invention is described below, and the preparation method comprises the following steps:

[0034] a. Active coating pretreatment, soaking the molecular sieve in the transition metal solution for at least 2 hours, removing the transition metal solution, drying and roasting the obtained molecular sieve to obtain a modified molecular sieve;

[0035] b. mixing the modified molecular sieve in the surfactant, the adhesive and the step a with an appropriate amount of water to obtain the active coating slurry;

[0036] c. Coating the active coating slurry on the honeycomb support by dipping or spraying, and obtaining the adsorption / catalysis material for exhaust gas treatment after the active coating is firmly bonded to the honeycomb support.

[0037] Due to the addition of high-performance adhesives, the loading capacity of the active coating on the honeycomb carrier i...

Embodiment 1

[0046] Take by weighing 1.6kg cordierite honeycomb ceramics and 0.2kg active coating, by weight, the active coating comprises the following components: 100 parts of molecular sieves, 2 parts of polyethylene glycol, 2.5 parts of copper nitrate solution of 0.1mol / L , 5 parts of adhesive; Among them, the adhesive is SiO 2 -Al 2 o 3 -ZrO 2 Composite sol.

[0047] SiO 2 -Al 2 o 3 -ZrO 2 The composite sol is prepared by the following method: add 5.0 g of zirconium nitrate to 4.1 g of ammonia water while stirring, and then add 2 g of oxalic acid to obtain a zirconium-containing sol; then add 15 g of aluminum isopropoxide to the zirconium-containing sol, stir evenly, and heat to 60℃, Al 2 o 3 -ZrO 2 Composite sol; after cooling to room temperature of about 25°C, add 10g of methyl orthosilicate to Al 2 o 3 -ZrO 2 in the composite sol, stir evenly, and heat to 65°C to obtain SiO 2 -Al 2 o 3 -ZrO 2 Composite sol.

[0048] Preparation process: Soak the above-mentioned mo...

Embodiment 2

[0050] Take by weighing 3.2kg ceramic fiber honeycomb and 0.35kg active coating, by weight, active coating comprises following components: 100 parts of molecular sieves, 3 parts of sodium carboxymethyl cellulose, chromium nitrate solution 1.0 of 0.4mol / L Parts, 15 parts of adhesive; Among them, the adhesive is SiO 2 -Al 2 o 3 -ZrO 2 Composite sol.

[0051] SiO 2 -Al 2 o 3 -ZrO 2 The composite sol is prepared by the following method: add 10.0g of zirconium nitrate to 8.1g of ammonia water while stirring, and then add 4g of citric acid to obtain a zirconium-containing sol; then add 25g of γ-alumina to the zirconium-containing sol, stir evenly, and heat to 70℃, Al 2 o 3 -ZrO 2 Composite sol; after cooling to room temperature of about 25°C, add 21g of methyl orthosilicate to Al 2 o 3 -ZrO 2 in the composite sol, stir evenly, and heat to 70°C to obtain SiO 2 -Al 2 o 3 -ZrO 2 Composite sol.

[0052] Preparation process: Soak the above-mentioned molecular sieve in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com