Tin phosphide/expanded graphite negative electrode composite material for sodium-ion battery and preparation method of tin phosphide/expanded graphite negative electrode composite material

A sodium-ion battery, expanded graphite technology, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of low energy density, low specific capacity of soft carbon negative electrodes, etc., to relieve volume expansion and good conductivity. , the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] In this embodiment, a tin phosphide / expanded graphite composite material with a carbon content of 16.7% by weight made of expanded graphite and tin phosphide is taken as an example. The sodium ion battery tin phosphide / expanded graphite negative electrode provided in this embodiment is tested through specific experiments. The effect of carbon content in the composite material on the electrochemical performance of the material is verified as follows:

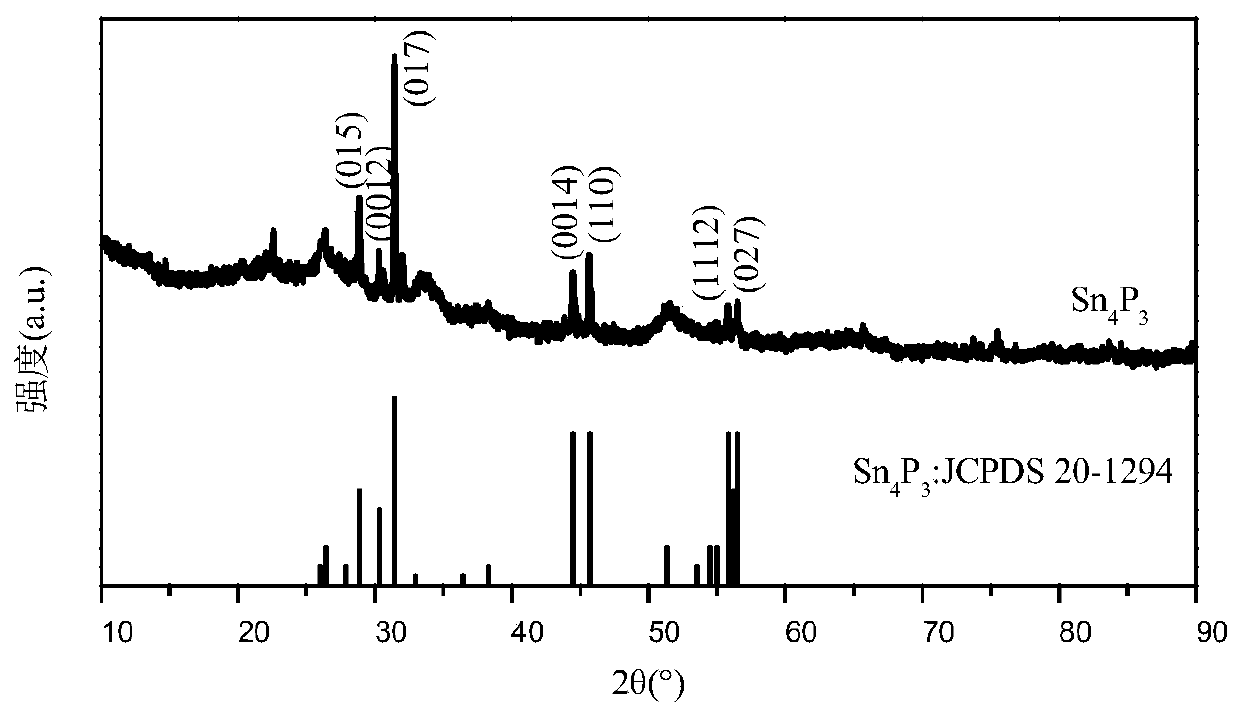

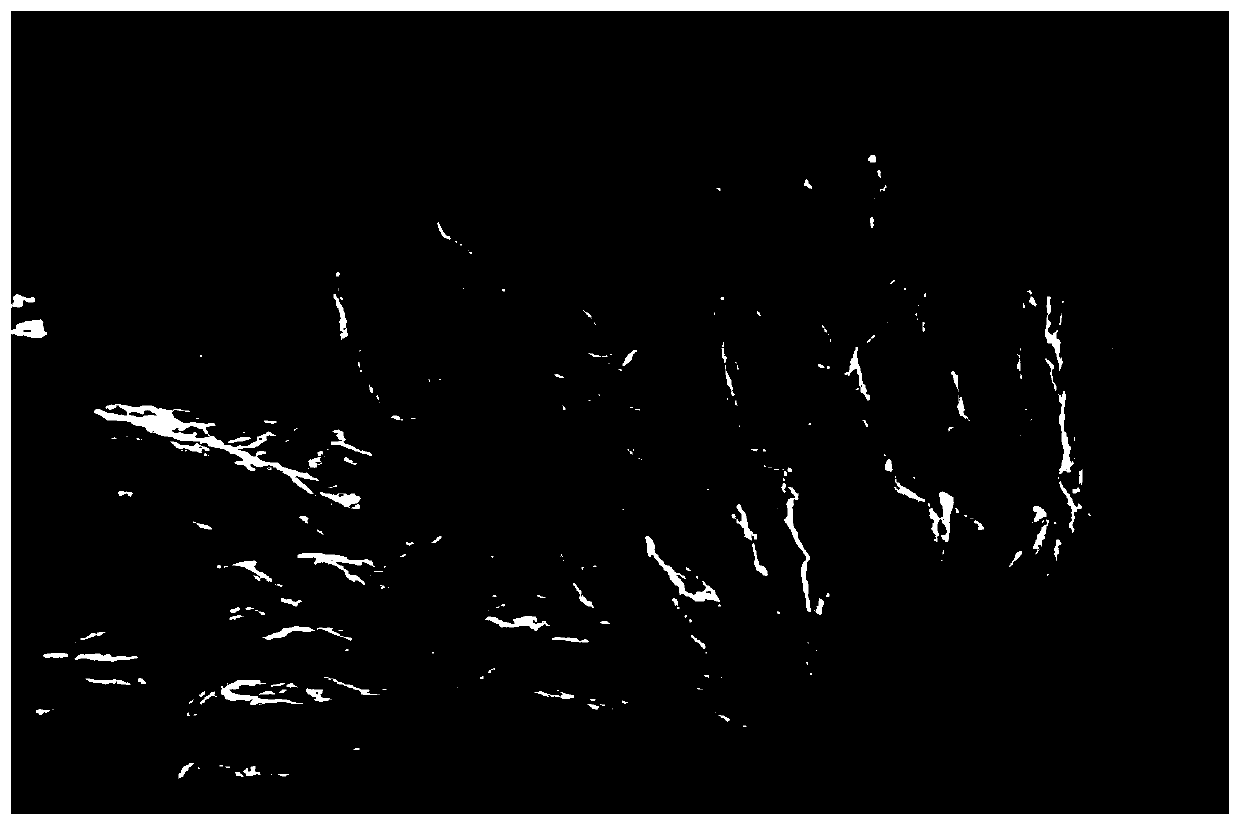

[0048] Weigh 0.375g surfactant CTAB, 4.5g NH 4 F, 0.1g Ti 2 (SO 4 ) 3 Dissolve in 400ml of deionized water, weigh 3g of tin tetrachloride and 10.8g of urea to dissolve in the above deionized water, heat it in an oil bath at 95°C, stir for 5h, filter and dry to obtain tin hydroxide. Weigh 6g of sodium hypophosphite and place it in the crucible upstream of the tube furnace, and place 0.4g of tin hydroxide in the crucible downstream. Under a nitrogen atmosphere, heat it to 350℃ at a heating rate of 5℃ / min and keep it for 1 hour. ...

Embodiment 2

[0053] In this embodiment, a tin phosphide / expanded graphite composite material with a carbon content of 10 wt% made of expanded graphite and tin phosphide is taken as an example, and the sodium ion battery phosphide tin / expanded graphite negative electrode composite material provided in this embodiment is tested through specific experiments. The effect of carbon content in the material on the electrochemical performance of the material is verified as follows:

[0054] In this example, compared with Example 1, the parameters of expanded graphite were adjusted from 0.1g to 0.055g, and other experimental conditions were the same as Example 1. Tin phosphide with a particle size of 100-200nm and a carbon content of 10wt% was prepared. Expanded graphite composite material. Next, the electrochemical performance of the composite material provided in this embodiment is analyzed.

[0055] The tin phosphide / expanded graphite composite material prepared in this embodiment is used to assemble...

Embodiment 3

[0057] In this embodiment, a tin phosphide / expanded graphite composite material with a carbon content of 30 wt% made of expanded graphite and tin phosphide is taken as an example. The sodium ion battery tin phosphide / expanded graphite negative electrode composite provided by this embodiment is tested through specific experiments. The effect of carbon content in the material on the electrochemical performance of the material is verified as follows:

[0058] In this example, compared with example 1, the parameters of expanded graphite are adjusted from 0.1g to 0.215g. The other experimental conditions are the same as that of example 1. A tin phosphide with a particle size of 100-250nm and a carbon content of 30wt% / expanded Graphite composite material.

[0059] The tin phosphide / expanded graphite composite material prepared in this embodiment is used to assemble a sodium ion battery. After 100 cycles of charging and discharging at a constant current of 500 mA / g at room temperature, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com