Base membrane suitable for coating, preparation method, lithium battery diaphragm and lithium ion battery

A technology of base film and casting sheet, which is applied in the field of lithium battery diaphragm and lithium ion battery, can solve the problems of low coating adhesion, peeling off, and low adhesion, so as to improve adhesion and enhance overall adhesion , the effect of not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

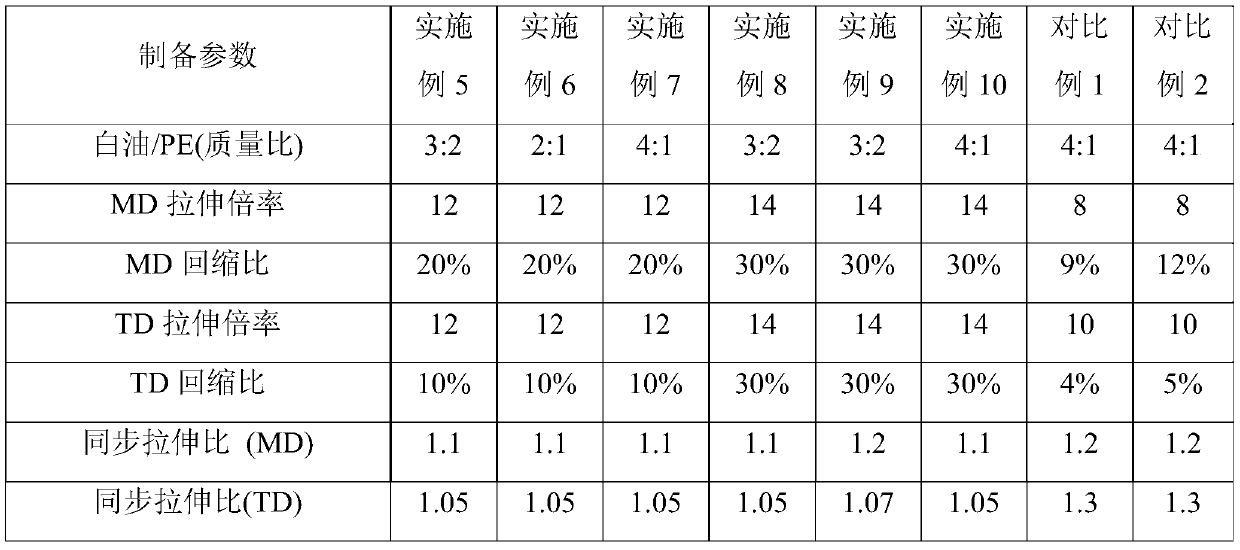

Examples

Embodiment 1

[0021] See figure 1 , this embodiment 1 provides a method for preparing a base film, comprising: mixing and melting raw materials to form a molten mixture; extruding the molten mixture to form a casting sheet; longitudinal stretching of the casting sheet; Transverse stretching; extraction; two-way synchronous secondary stretching; heat setting; and winding to obtain the base film.

[0022] Optionally, the raw material includes: white oil and polyethylene, and the mass ratio of the two is (3-8):2. Preferably, the mass ratio of white oil and polyethylene is 4:2.

[0023] Optionally, the sequence of longitudinal stretching of the cast sheet and transverse stretch of the cast sheet may be interchanged.

[0024] Optionally, the extraction solvent is such as but not limited to dichloromethane.

[0025] The preparation method of the base film in this embodiment 1 is mainly through the improvement of the processing technology in the preparation process, the surface structure and sur...

Embodiment 2

[0036] On the basis of Example 1, this Example 2 also provides a base film, the surface of the base film has a special concave-convex wrinkle structure, that is, the number of raised folds per square micron area on the surface of the base film is between 15- 35.

[0037] Specifically, the base film is prepared by the preparation method as described above to form the special concave-convex wrinkle structure on the surface of the base film, so as to improve the adhesion of the base film and the coating on the surface of the base film, and enhance the coating. The overall adhesion of the film makes the coating on the surface of the film not easy to fall off. The residual rate of the coating quality of the base film is above 25% after ultrasonic vibration for 1 hour.

[0038] Regarding the component content and specific implementation process of the base film, please refer to the relevant discussion in Example 1, which will not be repeated here.

Embodiment 3

[0040] On the basis of Example 2, this Example 3 also provides a lithium battery separator, including: the above-mentioned base film and a coating coated on the base film.

[0041] Wherein, the coating is, for example but not limited to, a coating slurry containing inorganic ceramic nanoparticles such as alumina, boehmite, and titanium dioxide, and polymers such as organic polyvinylidene fluoride.

[0042] Regarding the component content and specific implementation process of the base film, please refer to the relevant discussion in Examples 1-2, and will not repeat them here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| stretch ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com