Iron-based superconducting tape and preparation method thereof

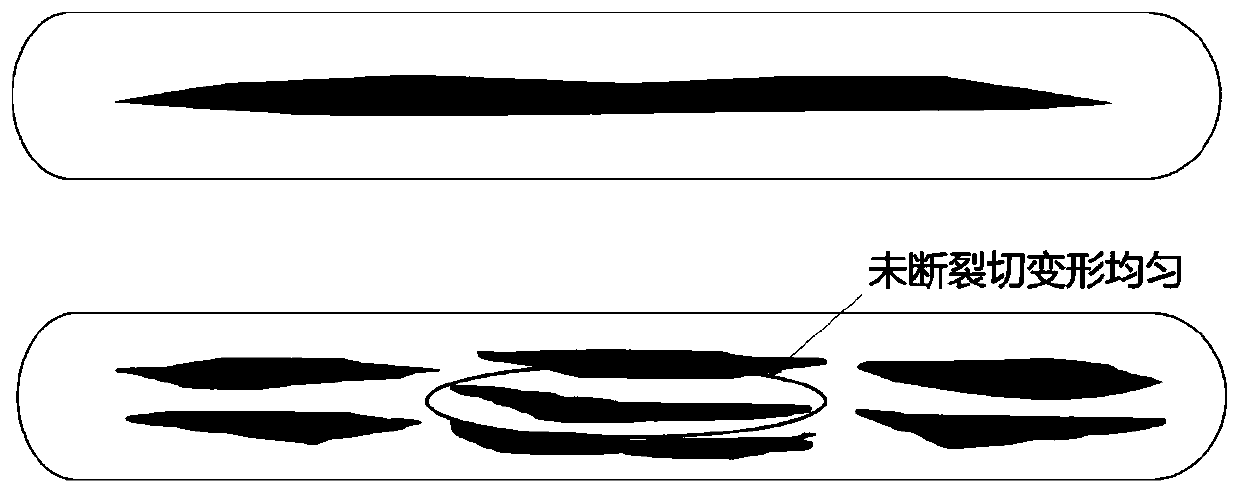

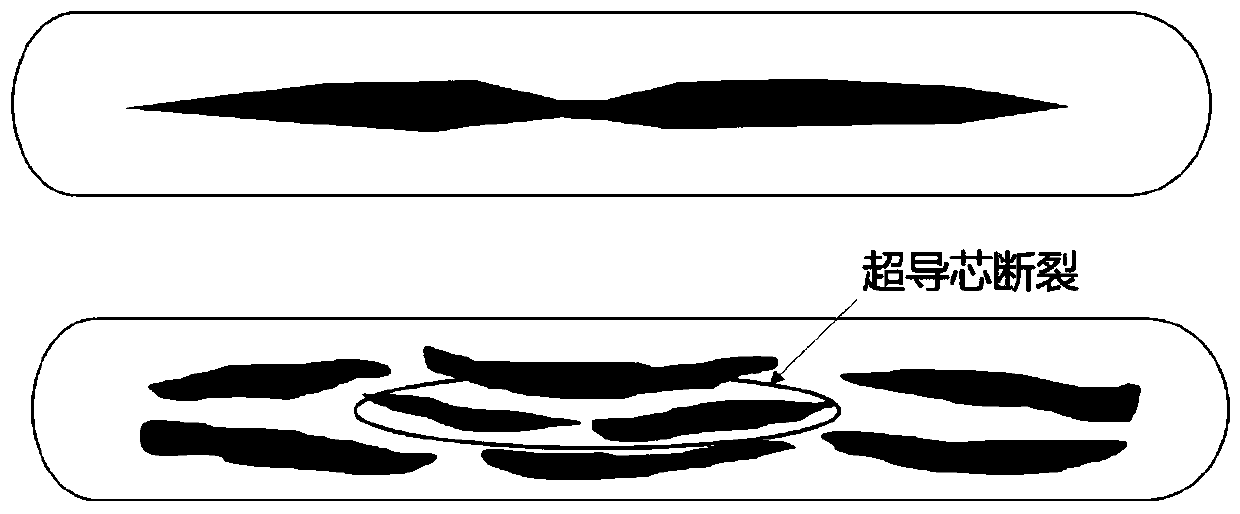

An iron-based superconductor and iron-based superconductor technology, which is applied in the usage of superconductor elements, superconducting devices, superconducting/high-conducting conductors, etc. Uneven changes in core thickness and width, etc., achieve consistent deformation, uniform deformation, and improve superconducting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment provides a single-core iron-based superconducting tape and a preparation method thereof. The preparation method includes the following steps,

[0035] Under an inert atmosphere, the simple substances of iron, potassium, barium and arsenic were mixed and ball-milled and then put into a niobium tube, and calcined for 35 hours at 900°C and 10Mpa to obtain an iron-based superconducting precursor powder (Ba 1-x K x Fe 2 As 2 ), then put the iron-based superconducting precursor powder into the silver tube, seal the two ends with a softer metal, swage, and draw the silver tube filled with the superconducting precursor powder circularly until the diameter of the iron-based superconducting wire is 2.1mm, and then use the square mold in Table 1 to draw the iron-based superconducting wire in a square shape until a square strip with a side length of 1.45mm and a rounded corner of 0.2mm is formed, and then roll it into a side length of 4mm and 0.3mm thick strips, ...

Embodiment 2

[0040] This embodiment provides a multi-core iron-based superconducting tape and a preparation method thereof. The preparation method includes the following steps,

[0041]Under an inert atmosphere, the simple substances of iron, potassium, barium and arsenic were mixed and ball-milled, put into a niobium tube, and calcined at 650 °C and 50 MPa for 10 h to obtain an iron-based superconducting precursor powder (Ba 1-x K x Fe 2 As 2 ), then put the iron-based superconducting precursor powder into the silver tube, seal the two ends with a softer metal, swage, and draw the silver tube filled with the superconducting precursor powder circularly until the diameter of the iron-based superconducting wire is 1.96mm, and then cut the round wire strip into 7 sections of the same length, and wipe it clean to obtain 7 superconducting cores, and then put them into a copper-silver alloy metal tube with an inner diameter of 6mm and an outer diameter of 8mm, Obtain composite wire;

[0042]...

Embodiment 3

[0044] This embodiment provides a single-core iron-based superconducting tape and a preparation method thereof. The preparation method includes the following steps,

[0045] Under an inert atmosphere, the simple substances of iron, sodium and arsenic were mixed and ball-milled and put into a niobium metal tube, and calcined for 35 hours at 900°C and 10Mpa to obtain iron-based superconducting precursor powder (NaFeAs), and then the iron-based superconducting precursor Put the powder into the silver tube, seal both ends with a softer metal, swage, and draw the silver tube filled with superconducting precursor powder circularly until the diameter of the iron-based superconducting wire is 1.95mm, and then use a square mold to shape the iron tube. The base superconducting wire is drawn in a square until a square strip with a side length of 1.55 mm and a rounded corner of 0.3 mm is formed, and then rolled into a strip with a side length of 3.8 mm and a thickness of 0.3 mm, and then r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com