A method for automatic and rapid digestion of food samples

A sample and fast technology, applied in the field of food hygiene physical and chemical inspection, can solve the problems of high labor intensity in screwing and cleaning tanks, many types of acids used, and small amount of digested samples, so as to achieve short digestion time and less reagent types and dosages. , the effect of avoiding the loss of mercury element

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

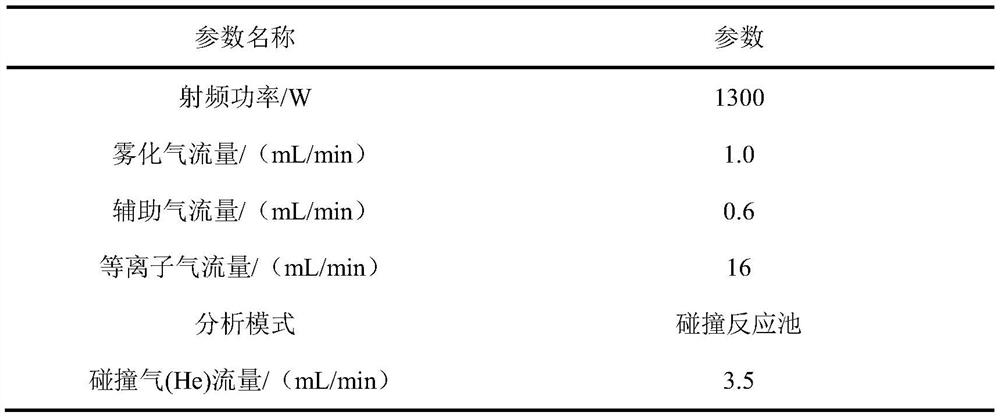

Method used

Image

Examples

Embodiment 1

[0056]

[0058]

Embodiment 2

[0062]

Embodiment 3

In the case of clarification, most of the components in the sample are decomposed or transferred to the acid solution, but a small number of elements such as chromium need to be

It can be transferred out only under certain digestion conditions (temperature greater than 160°C, time greater than 20min, and nitric acid consumption greater than 4mL). send

Mingren has found through many experiments that the digestion temperature is too low, the digestion time is too short, and the amount of the digestion reagent is too small, which will affect the digestion of the sample.

If the digestion temperature is too high, it will affect the life of the digestion tube; if the digestion time is too long, it will affect the working efficiency.

rate; excessive consumption of digestion reagents will increase labor costs and increase environmental pollution.

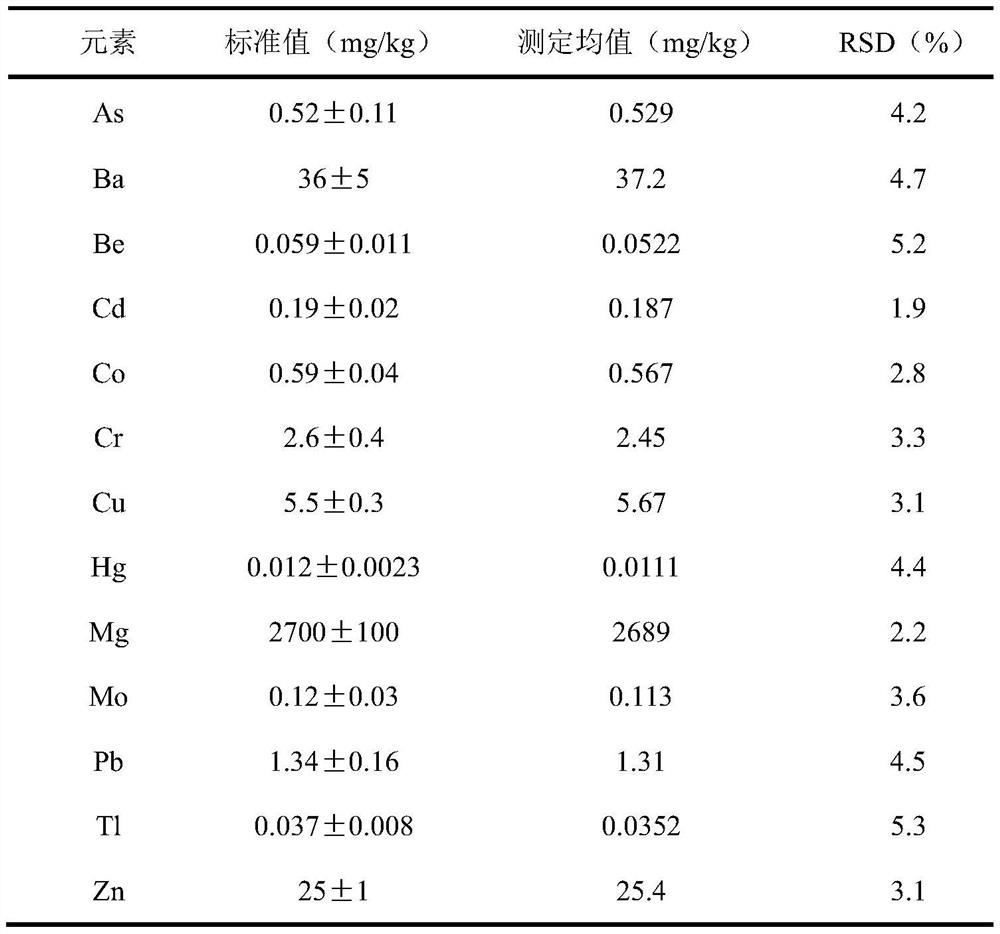

The measurement result (n=3) of part element in table 5 GBW10049 (GSB-27) green onion

[0069]

[0070] Continue the above table

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com