Flexible tactile sensor and preparation method thereof

A tactile sensor, flexible technology, applied in the field of sensing, can solve the problems of inability to measure and analyze three-dimensional stress, difficulty in separating normal stress and shear stress, and restricting the flexibility of sensors, etc., and achieve the effect of beautiful appearance, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

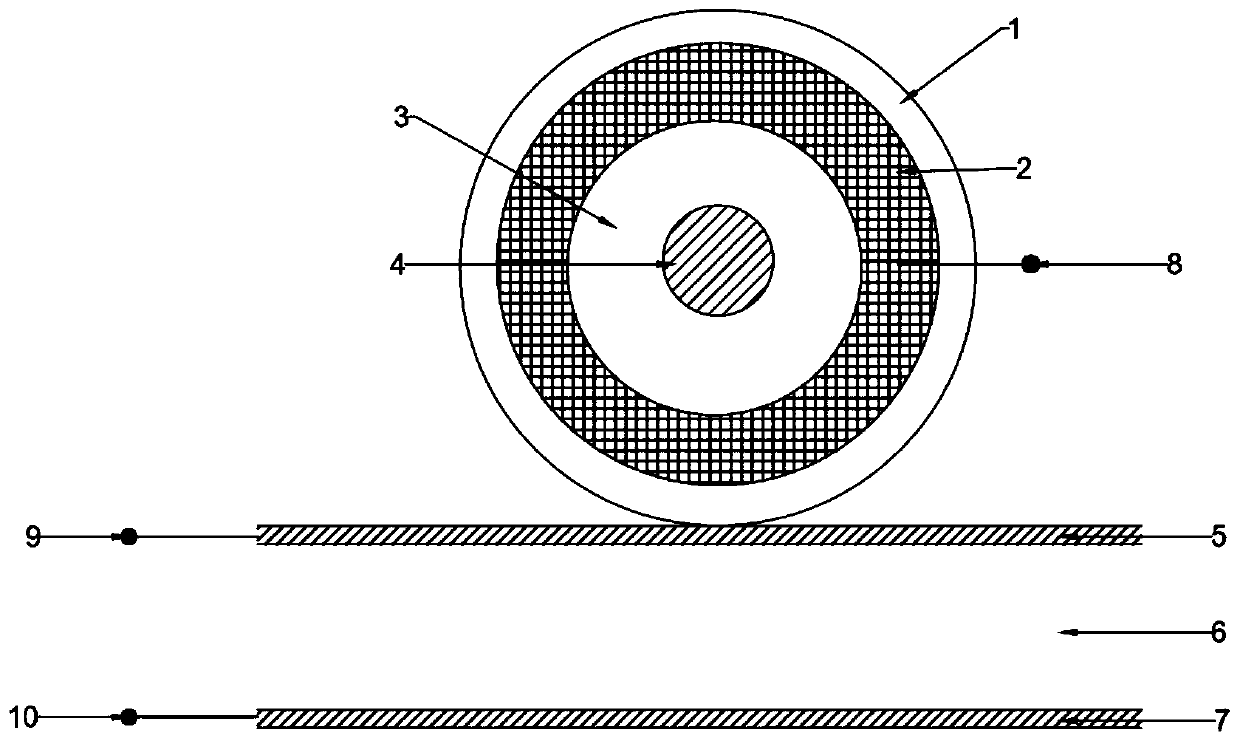

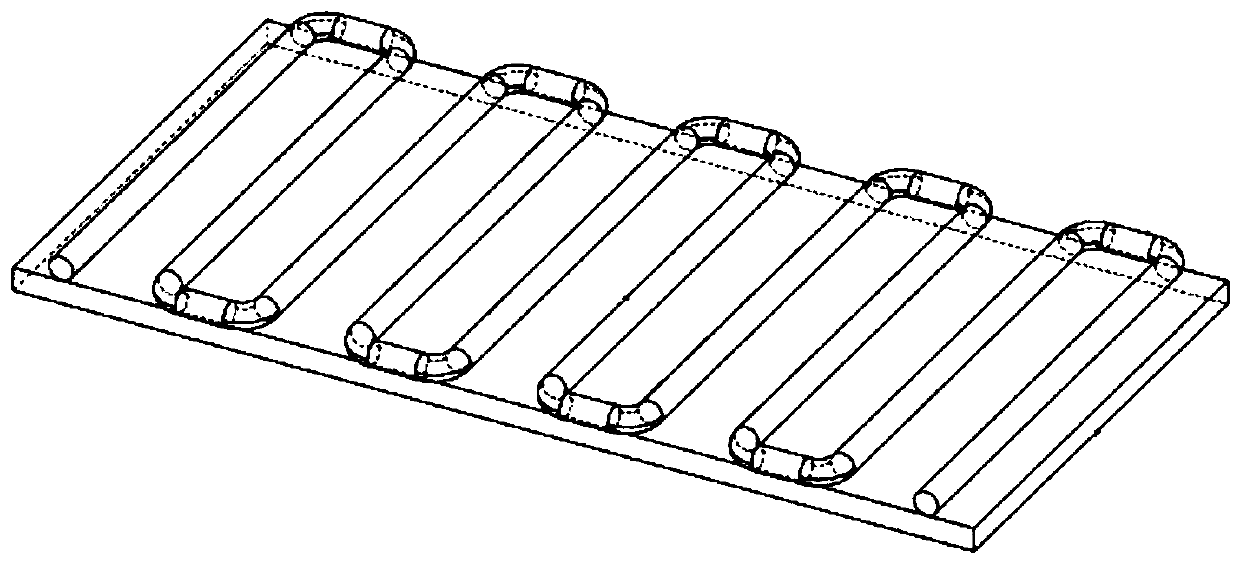

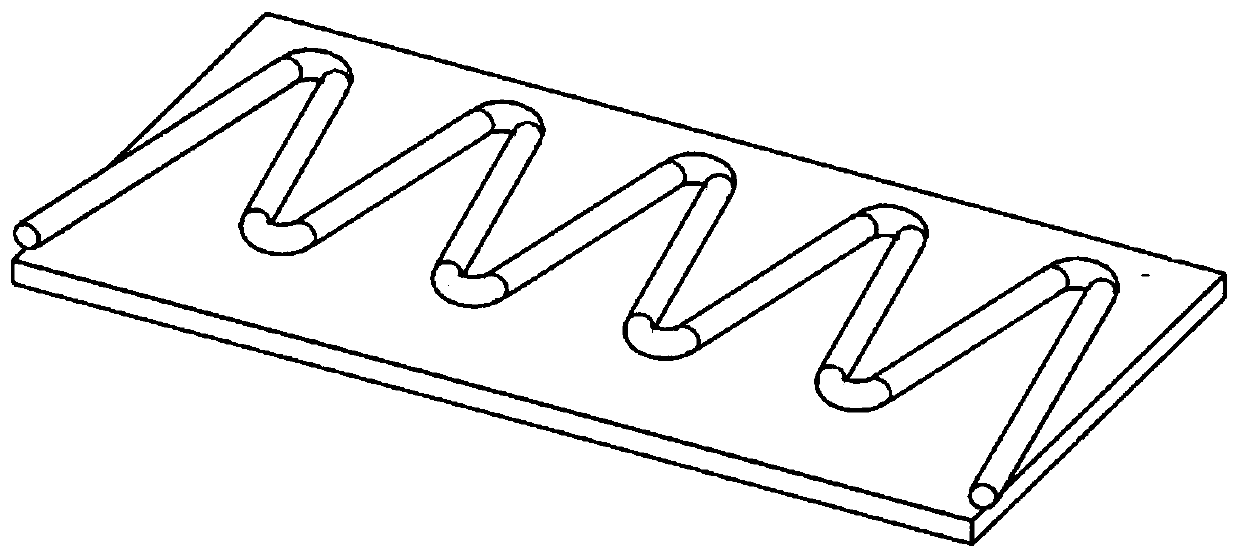

[0035] This embodiment provides a flexible tactile sensor. The flexible tactile sensor is composed of two parts connected by conductive glue, and has an upper and lower structure. The upper part is a piezoelectric electret cable sensing unit, and the lower part is a piezoelectric film sensing unit. The piezoelectric electret cable sensing unit is composed of four parts, coaxial connection structure, core electrode 4, piezoelectric electret layer 3, shielding layer 2 and sheath layer 1 in sequence from inside to outside. The innermost layer is the core electrode 4, the piezoelectric electret layer 3 is a porous piezoelectric electret film, the porous piezoelectric electret film is spirally wound to wrap the core electrode 4, and the porous piezoelectric electret film is made of a conductive material ( Such as copper or aluminum), the shielding layer 2 is braided and wrapped, and the outermost layer is a high-density polyethylene protective sheath, which is used to protect the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com