A rare earth electrolyzer repair paste and non-stop repair method

An electrolytic cell and rare earth technology, applied in the direction of electrolytic components, electrolytic process, etc., can solve the problems of reduced electrolytic efficiency and increased cost of electrolytic processing, and achieve the effects of reducing the number of shutdowns, reducing the waste of rare earth resources, and reducing the cost of new additions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of the above rare earth electrolytic cell repair paste is to prepare adhesive and dry material according to the above rare earth electrolytic cell repair paste, mix the adhesive and dry material and put them into a container to heat and soften; the container is a closed container with a pressure reducing valve , to prevent damage to the container due to excessive pressure during the heating process or other potential safety hazards, the heating temperature is 100° C. to 300° C., and the heating time is greater than or equal to 10 minutes.

[0026] A non-stop repairing method for a rare earth electrolytic cell, the repairing steps are as follows:

[0027] S1. Prepare the repair paste according to the preparation method of the above-mentioned rare earth electrolytic cell repair paste, and set it aside;

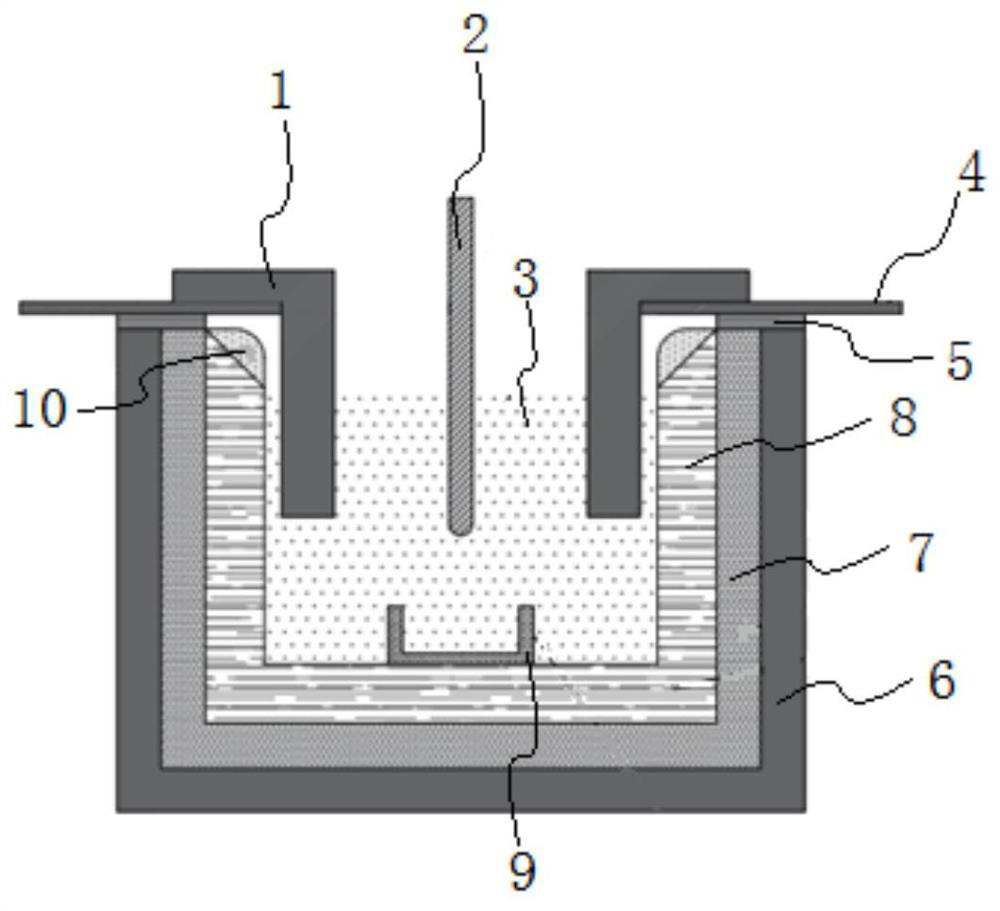

[0028] S2. During the production process, the anode block 1 closest to the damaged position 10 on the graphite tank body 8 of the rare earth electr...

Embodiment 1

[0033] A repair paste for a rare earth electrolytic cell, comprising the following components in parts by weight: 33 parts of tempered coal tar pitch containing coal tar, 27 parts of graphite powder, 54 parts of anthracite coal powder, and 19 parts of rare earth fluoride powder Among them, the graphite powder is a mixture of graphite powder with a particle size of 0.2mm and 4mm. The proportion of 0.2mm graphite powder is 28%, and the proportion of 4mm graphite powder is 72%.

[0034] The electrolytic cell of the rare earth dysprosium-iron alloy was repaired by using the above-mentioned non-stop repairing method for the rare earth electrolytic cell and the repairing paste for the rare earth electrolytic cell provided in this embodiment. After the repair, the loss rate of the graphite cell was significantly slowed down.

[0035] The filled repair paste material showed obvious loss around the 21st day, and a small amount of the upper edge of the graphite tank was exposed in the ai...

Embodiment 2

[0037] A repairing paste for a rare earth electrolytic cell, comprising the following components in parts by weight: 33 parts of tempered coal tar pitch containing coal tar, 26 parts of graphite powder, 54 parts of anthracite coal powder, and 20 parts of rare earth fluoride powder Among them, the graphite powder is a mixture of graphite powder with a particle size of 0.2mm and 4mm. The proportion of 0.2mm graphite powder is 28%, and the proportion of 4mm graphite powder is 72%.

[0038]The electrolytic cell of the rare earth dysprosium-iron alloy was repaired by using the above-mentioned non-stop repairing method for the rare earth electrolytic cell and the repairing paste for the rare earth electrolytic cell provided in this embodiment. After the repair, the loss rate of the graphite cell was significantly slowed down.

[0039] The filled repair paste material showed obvious loss around the 25th day, and a small amount of the upper edge of the graphite tank was exposed in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com