A kind of anhydrous chrome tanning process

A chrome tanning and process technology, applied in the field of chrome tanned leather, can solve the problems of low utilization rate of chrome tanning agent, affecting the quality of finished leather, and uneven distribution of chromium, so as to avoid the generation of chromium-containing waste liquid, and the operation of feeding and collecting is simple , The effect of uniform surface color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

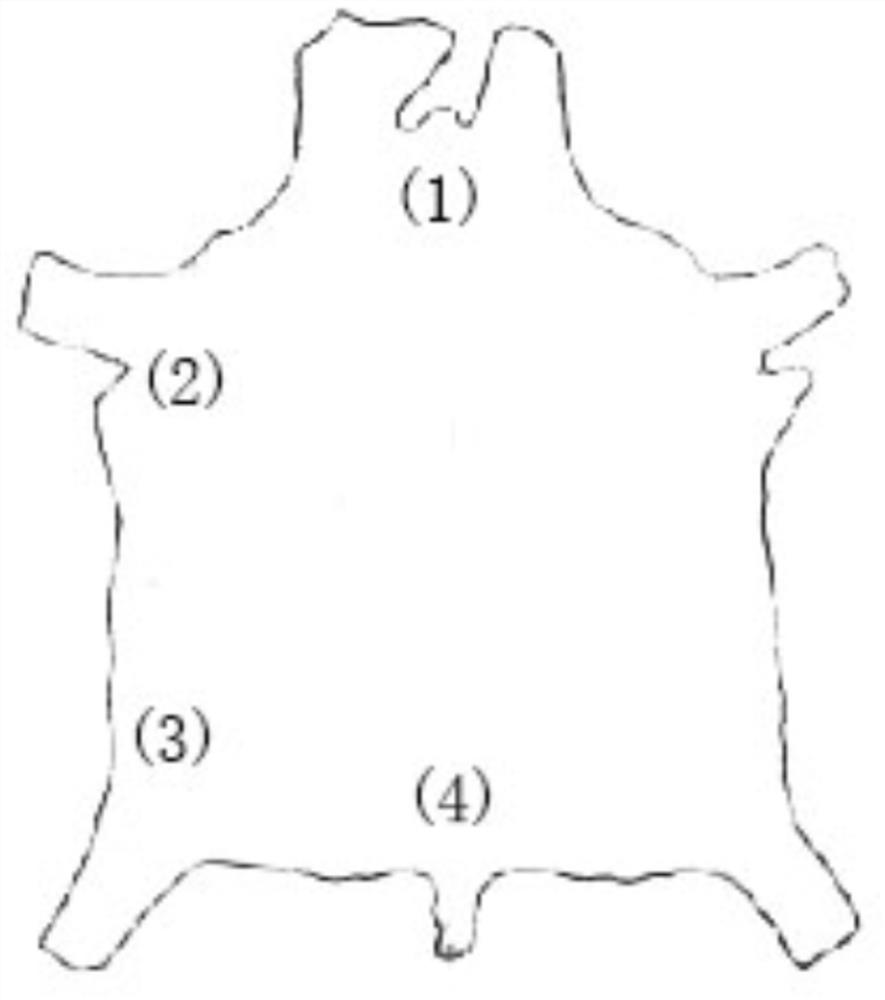

Image

Examples

Embodiment 1

[0030] Preparation of chrome tanned leather: use pickled sheepskin, add 40% plastic balls, 2% cationic fatliquoring agent, turn for 0.5h, add 4% chrome tanning agent (the chrome tanning agent is added after dissolving in 4% water), turn for 2.0h , add 0.8% magnesium oxide, turn for 2.0 h, heat up to 40°C, turn for 1.0 h, stop overnight, turn for 1.0 h the next day, and leave the drum to get chrome tanned leather.

[0031] The density of plastic balls is 2.0g / cm 3 , with a size of 1.0mm, the plastic balls are recycled by magnetic force and can be directly used for the next tanning.

Embodiment 2

[0033] Preparation of chrome tanned leather: use pickled sheepskin, add 60% plastic balls, 4% anionic fatliquoring agent, turn for 0.5h, add 5% chrome tanning agent (the chrome tanning agent is added after dissolving in 4% water), turn for 2.0h , add 1.5% sodium bicarbonate in 5 times, rotate the drum for 20 minutes after each addition, measure the pH, when the pH is 3.8~4.0, stop adding sodium bicarbonate, turn for 0.5 h, heat up to 40 ℃, turn to 1.0 h, stop overnight, turn 1.0 h the next day, and get out of the drum to get chrome tanned leather.

[0034] The density of plastic balls is 0.2g / cm 3 , with a size of 3.0mm, the plastic balls are recycled by wind and can be directly used for the next tanning.

Embodiment 3

[0036]Preparation of chrome tanned leather: use pickled sheepskin, add 50% plastic balls, 3% non-ionic fatliquoring agent, turn for 0.5h, add 3% chrome tanning agent (the chrome tanning agent is added after dissolving in 3% water), turn 2.0 h, add 2% sodium formate in 5 times, rotate the drum for 20 minutes after each addition, measure the pH, when the pH is 3.8~4.0, stop adding sodium formate, turn for another 0.5 h, heat up to 40 °C, turn for 1.0 h, stop Overnight, turn for 1.0 h the next day, and get out of the drum to get chrome tanned leather.

[0037] The density of plastic balls is 0.8 g / cm 3 , the size is 10.0mm, the plastic balls are manually recycled and can be directly used for the next tanning.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com