Waterborne polyurethane for flocking adhesive and preparation method thereof

A water-based polyurethane and flocking adhesive technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc. Maintain the effect of wear resistance, good water resistance and good softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

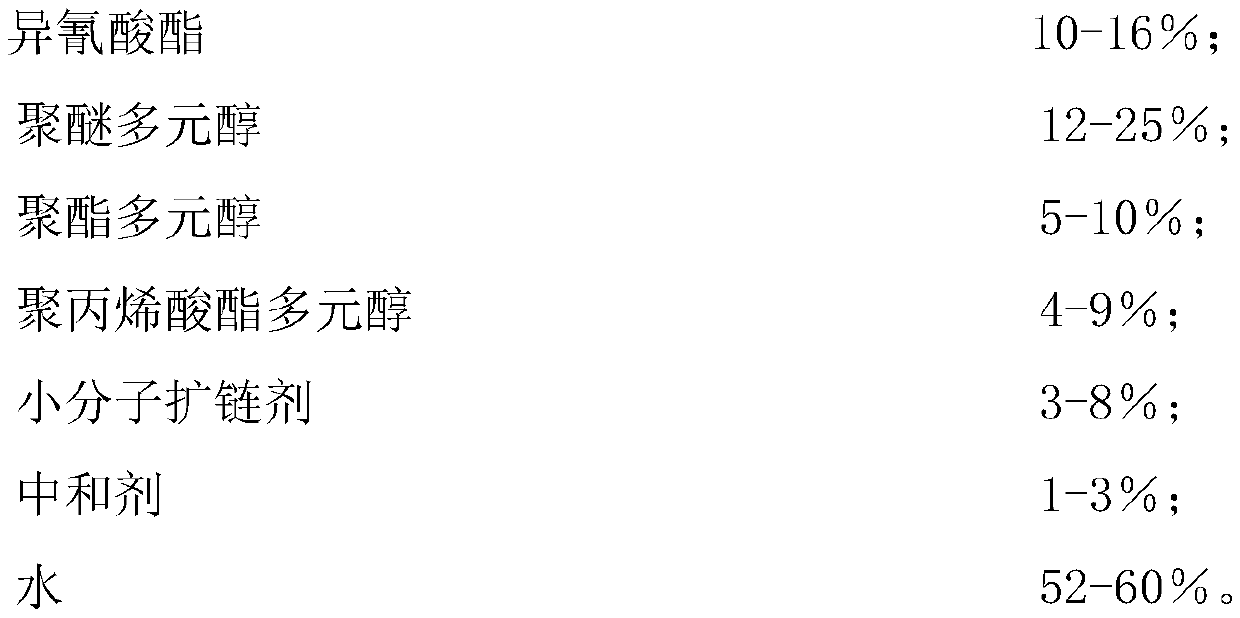

[0020]

[0021] Take the following process to prepare:

[0022] S1. Melt and mix PTMEG, polycarbonate diol PCD, and polyacrylate polyamine at 125°C for 1.5 hours, and vacuum dehydrate for 2 hours until the water content of the material is lower than 400ppm; the lower the water content, the better Control of prepolymer synthesis;

[0023] S2. Prepolymerization: react the isocyanate and the dehydrated polyol component at 85°C for 2 hours;

[0024] S3. Chain extension: add DMPA and TMP to the prepolymer, and perform chain extension reaction at 75°C for 3 hours until the NCO content is close to the theoretical value;

[0025] S4. Neutralization and emulsification: lower the temperature of the prepolymer to 55°C, add a neutralizer and stir quickly for neutralization, and emulsify the prepolymer in water after 30 minutes of neutralization;

[0026] S5. Post-chain extension: Dissolve IPDA in an appropriate amount of water and drop it into the emulsion for post-chain extension. ...

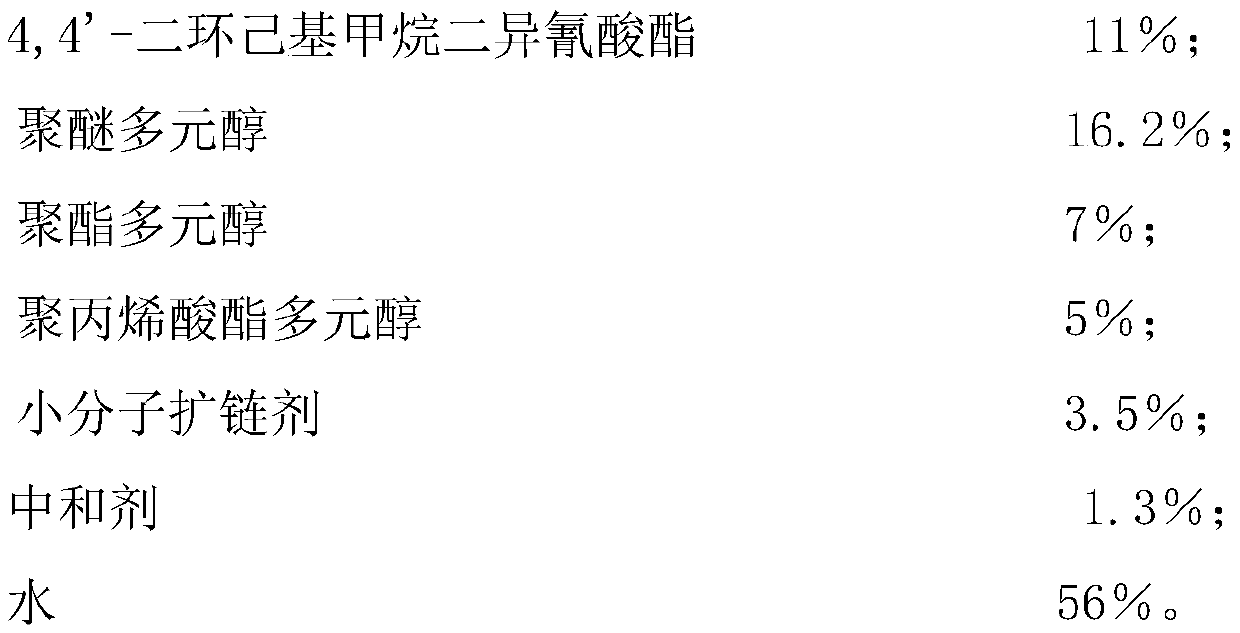

Embodiment 2

[0028]

[0029] Take the following process to prepare:

[0030] S1. Melt and mix polyether polyols PPG, PCD, and polyacrylate polyols at 120°C for 1.5 hours, vacuumize and dehydrate for 2 hours, until the water content of the materials is lower than 400ppm;

[0031] S2. Prepolymerization: react the isocyanate and the dehydrated polyol component at 85°C for 2 hours;

[0032] S3. Chain extension: add DMPA and TMP to the prepolymer, and perform chain extension reaction at 75°C for 2.5 hours until the NCO content is close to the theoretical value;

[0033] S4. Neutralization and emulsification: lower the temperature of the prepolymer to 55°C, add a neutralizer and stir quickly for neutralization, and emulsify the prepolymer in water after 30 minutes of neutralization;

[0034] S5. Post-chain extension: EA is dissolved in an appropriate amount of water and dropped into the emulsion for post-chain extension.

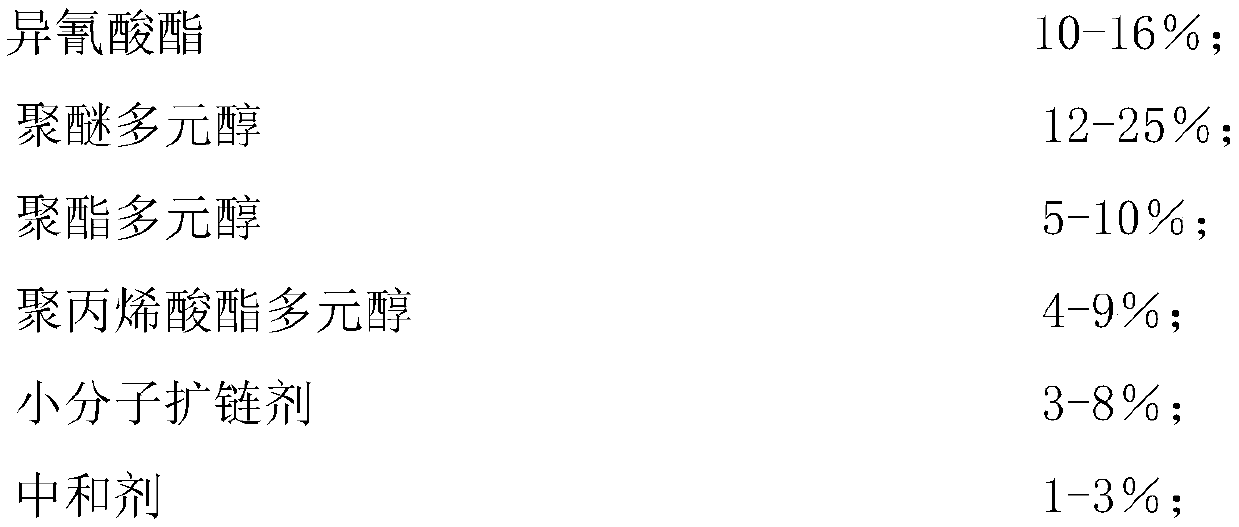

Embodiment 3

[0036]

[0037]

[0038] Take the following process to prepare:

[0039] S1. Melt and mix PTMEG, PCD, and polyacrylate polyol at 125°C for 1.5 hours, and vacuum dehydrate for 2 hours until the water content of the material is lower than 400ppm;

[0040] S2. Prepolymerization: react IPDI and dehydrated polyol components at 85°C for 2 hours;

[0041] S3. Chain extension: Add DMBA and TMP to the prepolymer, and perform chain extension reaction at 75°C for 3 hours until the NCO content is close to the theoretical value;

[0042] S4. Neutralization and emulsification: lower the temperature of the prepolymer to 55°C, add TEA to quickly stir for neutralization, and emulsify the prepolymer in water after 30 minutes of neutralization;

[0043] S5. Post-chain extension: Dissolve IPDA in an appropriate amount of water and drop it into the emulsion for post-chain extension.

[0044] Use the water-based polyurethane flocking glue formulated above, and use the same compound formula ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com