Preparation technology of kaolin for large thin-plate bricks

A preparation process, a technology of kaolin, applied in the field of preparation process of kaolin for thin-plate large bricks, can solve the problems of inability to increase the length and width, and achieve the effects of improving flexural strength and plasticity, strong adsorption capacity, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: A kind of preparation technology of kaolin for thin plate large brick, and prepare and obtain through following steps:

[0042]Step 1: Mining to remove impurities, mining Zhangzhou kaolin mineral material, and preliminarily separating clay and impurities to obtain kaolin base material; Step 2: pulping and removing sand, pulping kaolin base material and performing sand removal to obtain kaolin slurry initial material;

[0043] Step 3: chemical bleaching, transporting the primary kaolin slurry to the slurry storage tank of the high-speed mixing tank, adding sulfuric acid solution and sodium dithionite solution, the mass ratio of the sulfuric acid solution to the primary kaolin slurry is 0.3:100 to 0.8:100, The mass ratio of sodium dithionite solution to kaolin slurry primary material is 0.6:100~1.0:100, adjust the pH value of the mixed solution to 2.0~3.0, and stir at a speed of 140~180 rpm for 40~45 minutes in a high-speed mixing tank , to obtain kaolin sl...

Embodiment 2

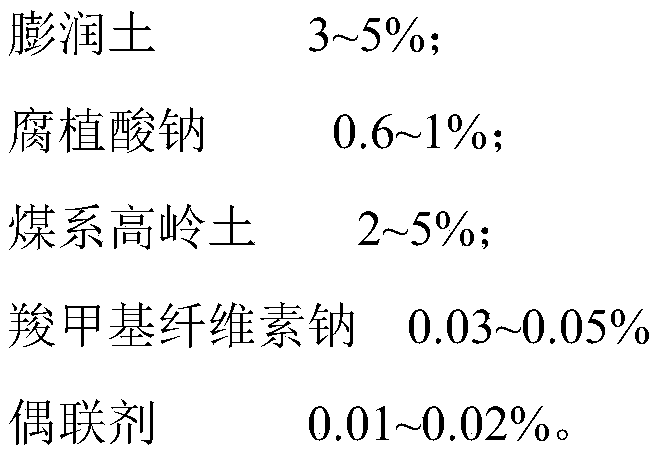

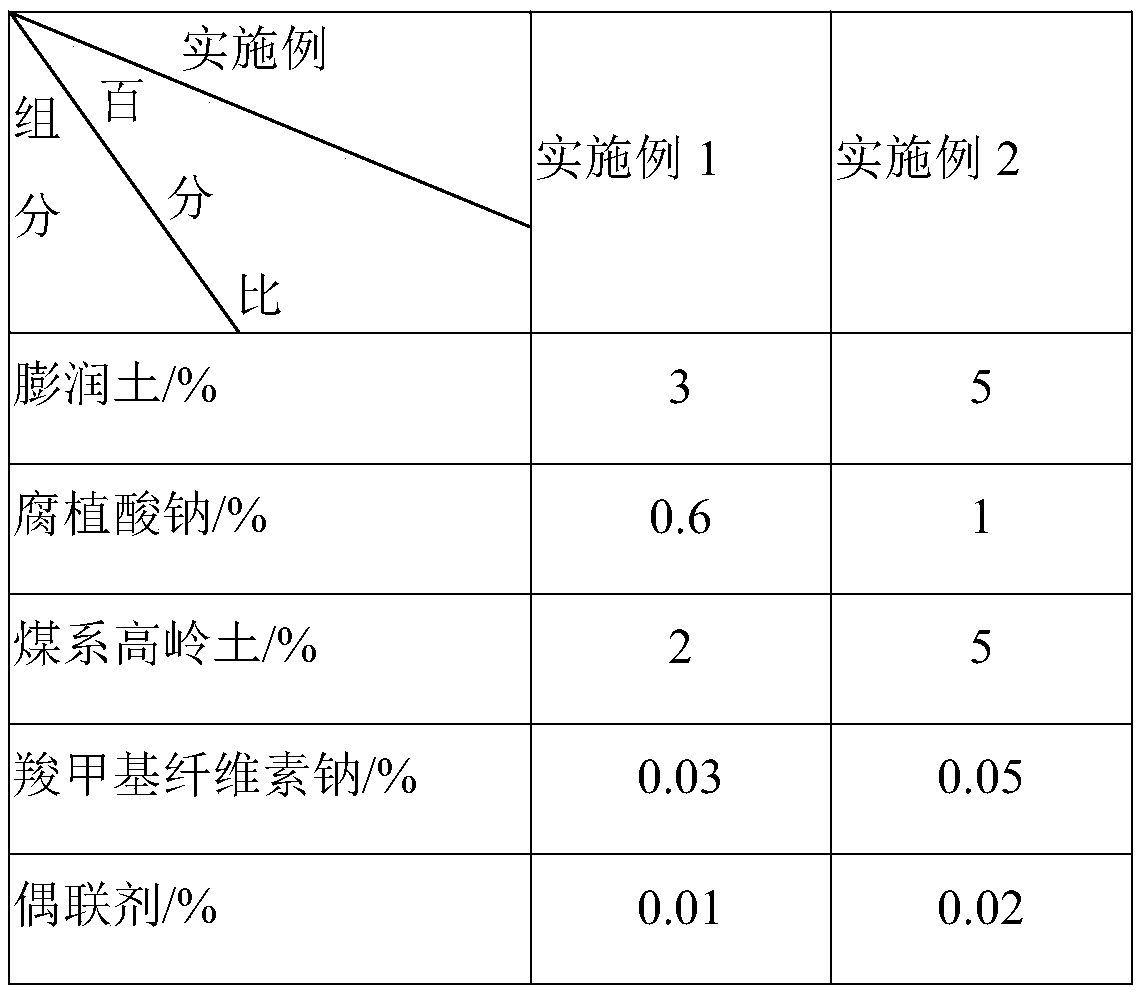

[0050] Example 2: A preparation process of kaolin for large thin-slab bricks. The difference from Example 1 is that the components of the modified material in Step 6 and their corresponding weight percentages are shown in Table 1.

[0051] Each component and weight percentage thereof in table 1 embodiment 1-2

[0052]

Embodiment 3

[0053] Example 3: A preparation process of kaolin for thin-slab bricks. The difference from Example 1 is that the weight ratio of the modified material in step 6 to the kaolin intermediate filter cake is 1:8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com