An environment-friendly metallic texture permeable pavement material

A metal texture, permeable pavement technology, applied in roads, roads, fibrous fillers, etc., can solve the problems of poor freeze-thaw cycle and noise reduction performance of concrete pavement, poor resistance to water damage of asphalt, and large gaps between particles. Good freeze-thaw cycle performance, bright and diverse colors, and low dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

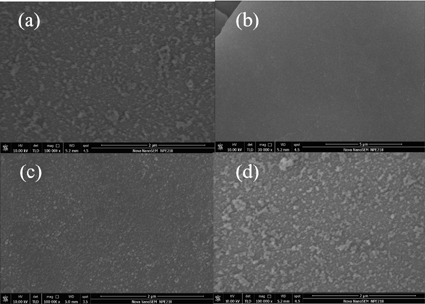

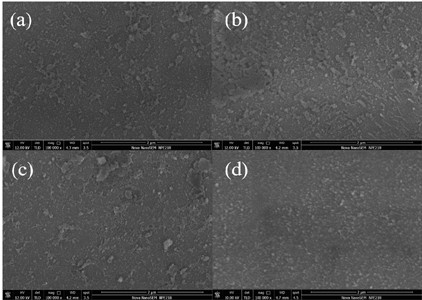

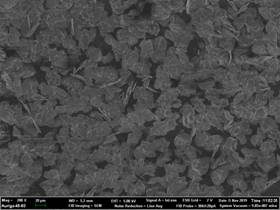

Embodiment 1

[0025] A kind of nano-SiO 2 The preparation method of film-coated flaky aluminum pigments comprises the following steps: ①Add 2.7g of pretreated aluminum powder and 67.5mL of absolute ethanol into a 250 mL four-neck flask, and then heat up to 50°C; Add liquid A and liquid B dropwise into the pressure dropping funnel at the same time. After the dropwise addition, raise the temperature to 80°C, react for 3 hours, and then filter and dry to obtain nano-SiO 2 Film-coated flaky aluminum pigments; solution A is 40.5 mL of TEOS ethanol solution (6g of TEOS), solution B is a mixed solution of 40.5 mL of ethanol, ammonia water and water (4.9 mL of ammonia water diluted with absolute ethanol and 10.8 mL of water ), the dropping speed of liquid A and liquid B is 1 drop / second.

Embodiment 2

[0027] A kind of nano-SiO 2 The preparation method of film-coated flaky aluminum pigments comprises the following steps: ①Add 2.7g of pretreated aluminum powder and 67.5mL of absolute ethanol into a 250 mL four-necked flask, and then heat up to 45°C; Add liquid A and liquid B dropwise into the pressure dropping funnel at the same time. After the dropwise addition, raise the temperature to 80°C, react for 4 hours, and then filter and dry to obtain nano-SiO 2 Film-coated flake-shaped aluminum pigment; liquid A is 40.5 mL of TEOS ethanol solution (7g of TEOS), and liquid B is a mixed solution of 40.5 mL of ethanol, ammonia water and water (4.9 mL of ammonia water diluted with absolute ethanol and 10.8 mL of water ), the dropping speed of liquid A and liquid B is 1 drop / second.

Embodiment 3

[0029] A kind of nano-SiO 2 The preparation method of film-coated flaky aluminum pigments comprises the following steps: ①Add 2.7g of pretreated aluminum powder and 67.5mL of absolute ethanol into a 250 mL four-neck flask, and then heat up to 55°C; Add liquid A and liquid B dropwise into the pressure dropping funnel at the same time. After the dropwise addition, raise the temperature to 80°C, react for 3 hours, and then filter and dry to obtain nano-SiO 2 Film-coated flaky aluminum pigments; solution A is 40.5 mL of TEOS ethanol solution (6.5 g of TEOS), solution B is a mixed solution of 40.5 mL of ethanol, ammonia and water (4.9 mL of ammonia diluted with absolute ethanol and 10.8 mL of water), the dropping speeds of liquid A and liquid B are both 1 drop / second.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com