Self-adaptive planning method for stacking type of bagged material loading

An adaptive, material-based technology, applied in the stacking, loading/unloading, transportation, and packaging of objects, can solve problems such as poor stability and danger to logistics vehicle drivers, and achieve high stability and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

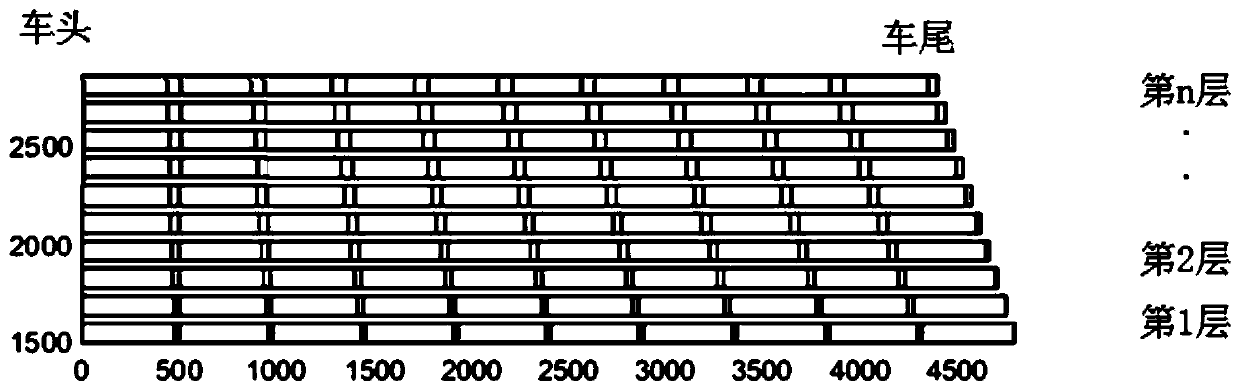

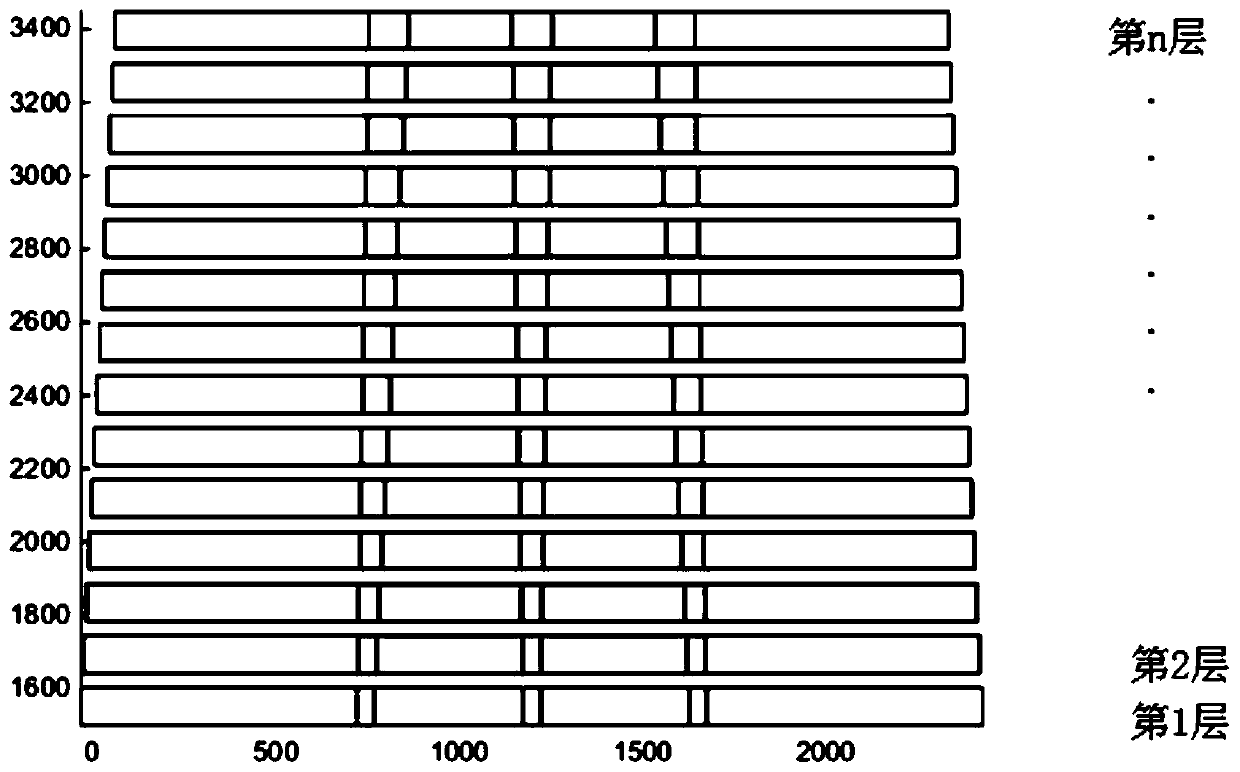

[0021] see Figure 1-3 , an adaptive planning method for bagged material loading into trucks and pallets, including the following steps:

[0022] 1. Obtain the size of the logistics vehicle compartment and the size of the bagged materials that need to be loaded;

[0023] 2. Layered design of stacking type and stacking type parameters

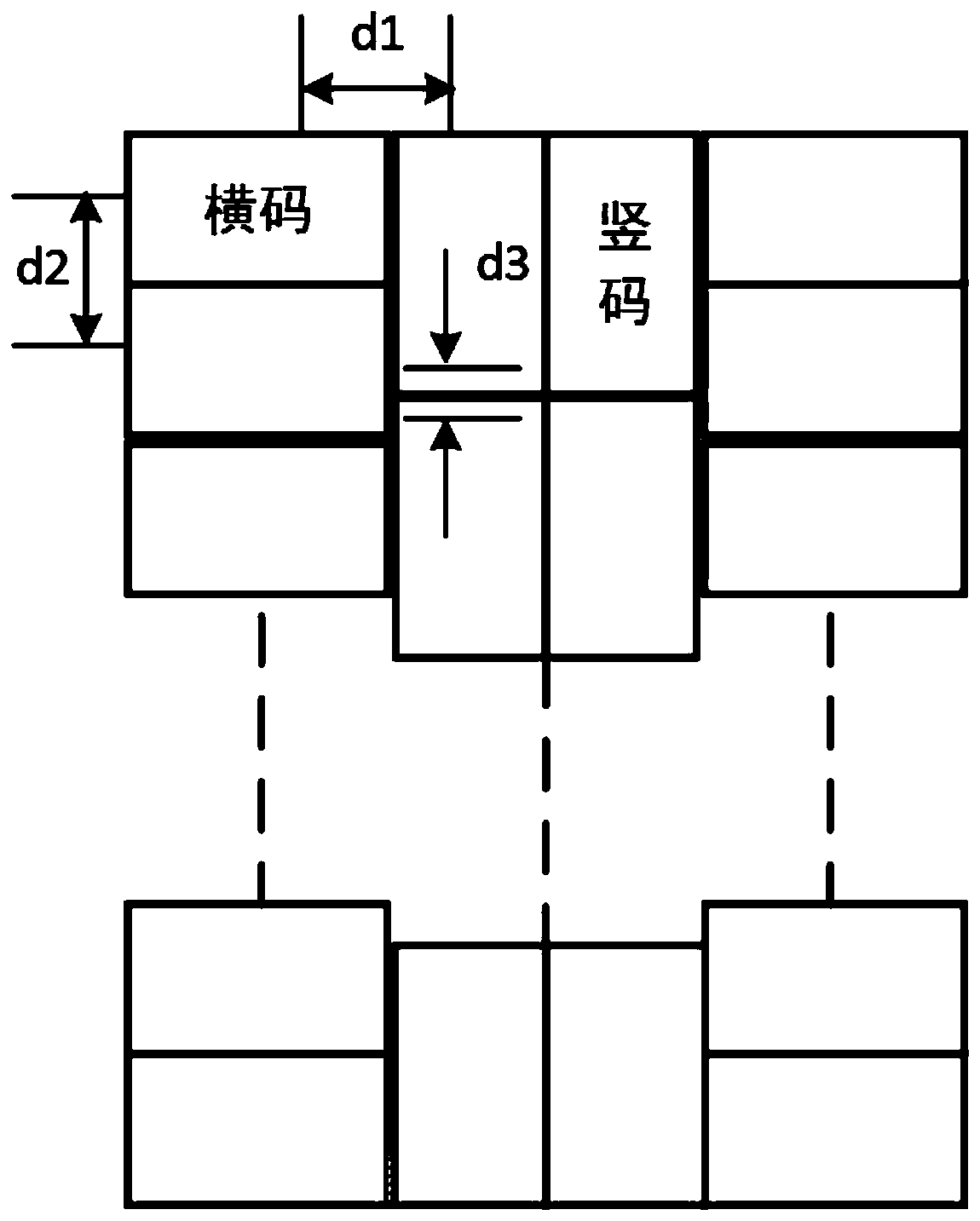

[0024] (1) First plan the stacking method of the first layer of materials in the carriage, such as figure 1 It is the stacking type of the low-profile model. This type of stacking is left-right symmetrical. Not only is the stacking type stable and the complexity of the stacking type is low, the robot grabs the material in a simple way, the robot posture changes less, and the loading efficiency is high;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com