Positioning and grooving mechanism for pipe pile end square plate

A technology for pipe piles and slab grooves, which is applied in the field of positioning and grooving mechanisms, can solve problems such as reducing engineering efficiency and increasing installation difficulty, and achieves the effects of reducing construction difficulty, increasing construction efficiency, and reducing grooving difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

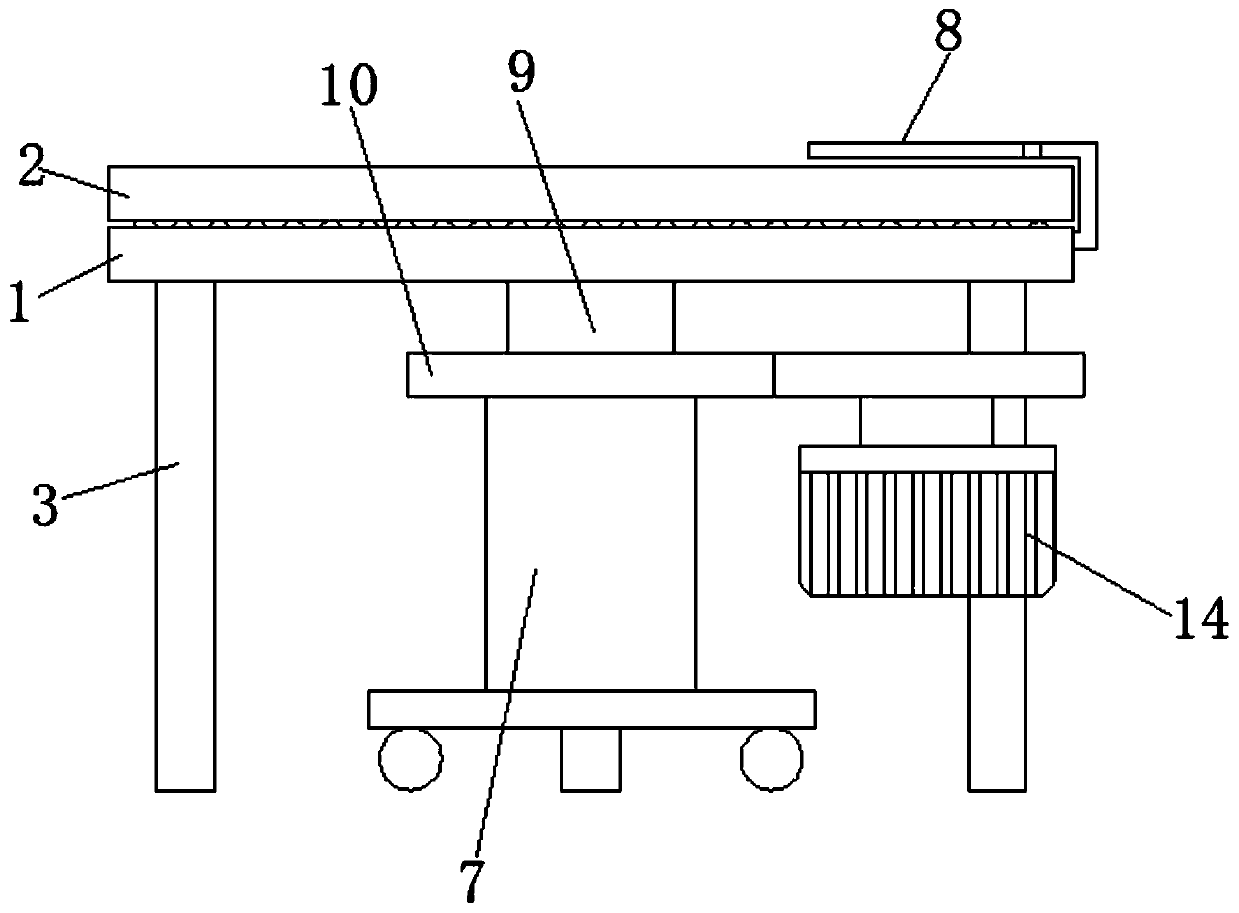

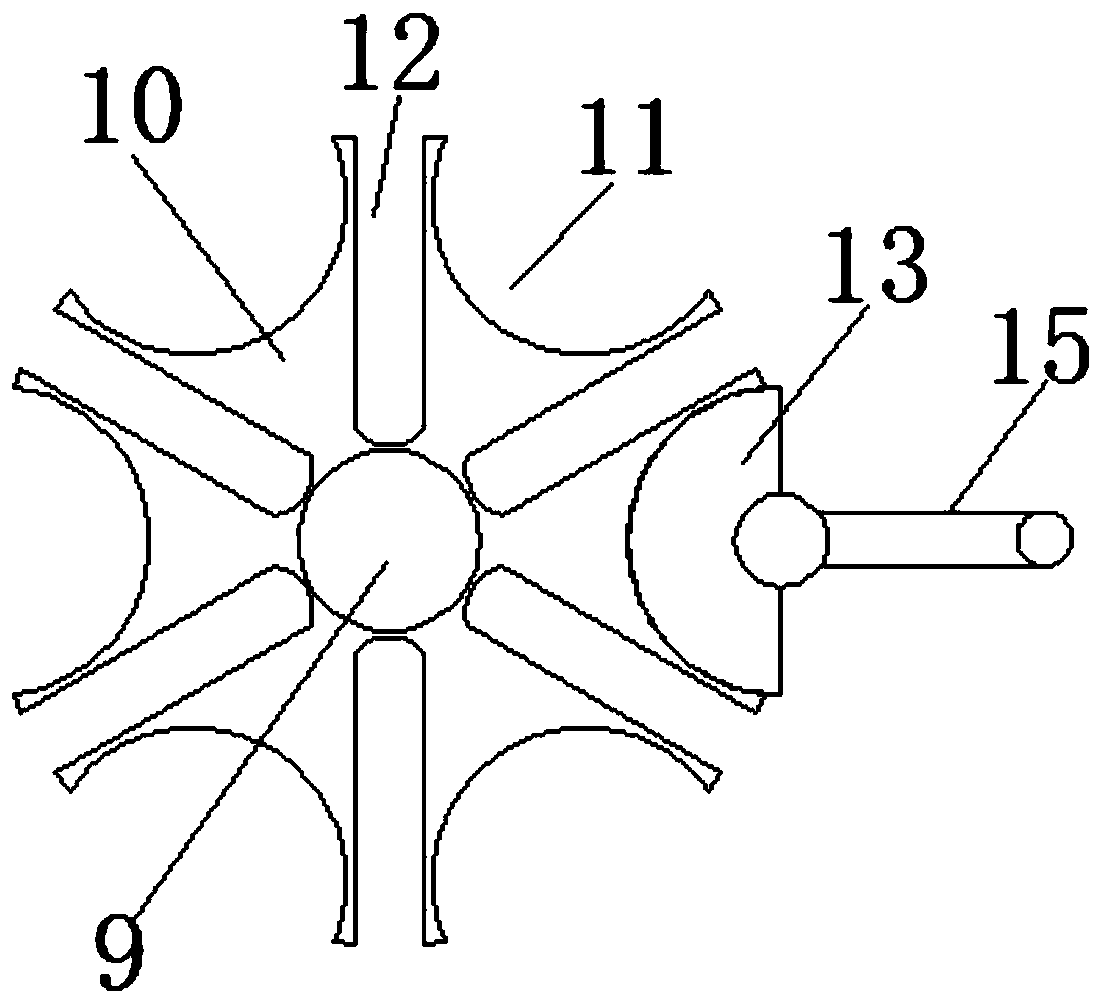

[0032] see Figure 1-7 , according to an embodiment of the present invention, a positioning and slotting mechanism for a square plate at the end of a pipe pile includes a bottom plate 1, a panel 2 is arranged on the bottom plate 1, and a plurality of support legs 3 are fixed under the bottom plate 1, Said panel 2 is evenly provided with square plate grooves 4, wherein one of the square plate grooves 4 is provided with a stamping machine 5, and one of the square plate grooves 4 is a blanking square plate groove, and the bottom of the blanking square plate groove is provided with a The bottom plate 1 is provided with a blanking through hole 6, a material receiving mechanism 7 is placed under the blanking through hole 6, and a blanking mechanism is arranged on the plurality of square plate grooves 4. One side of the blanking mechanism An interception mechanism 8 is provided, and a transmission rod 9 is fixed at the lower end of the middle part of the panel 2, and the transmission...

Embodiment 2

[0035] see Figure 1-7 , for the bottom plate 1, an annular groove 16 is opened on the bottom plate 1, and a plurality of rollers 17 are arranged in the annular groove 16, and a square plate 18 is placed on the roller 17.

[0036] As for the base plate 1 , a through hole is opened on the base plate 1 , and a bearing is embedded in the through hole, and the transmission rod 9 is connected with the base plate 1 through the bearing.

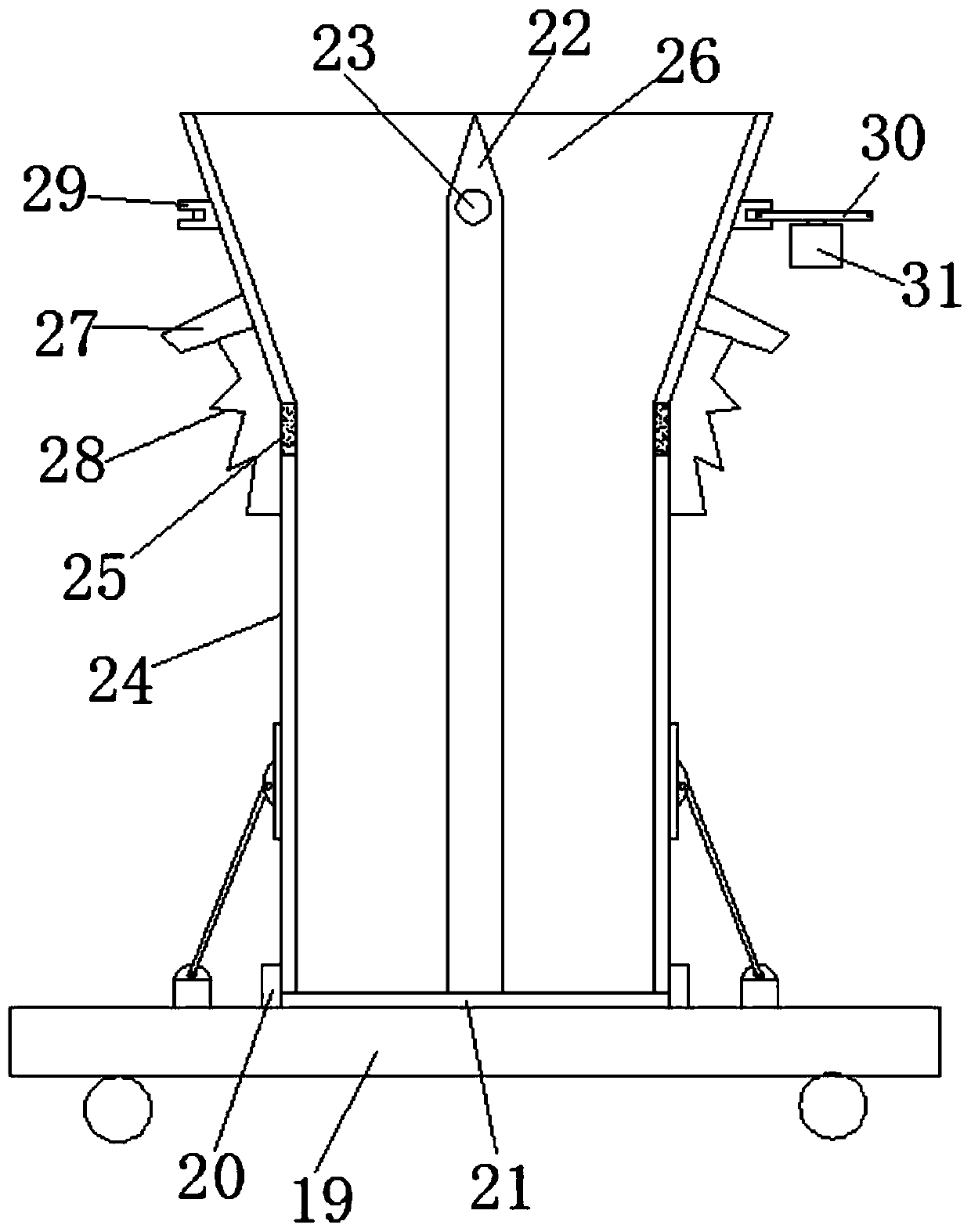

[0037] For the material receiving mechanism 7, the material receiving mechanism 7 includes a base 19, the base 19 is provided with a placement groove 20, the placement groove 20 is provided with a horizontal plate 21, and the horizontal plate 21 is fixedly provided with Insert rod 22.

[0038] For the insertion rod 22, a lifting hole 23 is provided on the insertion rod 22, and the side length of the horizontal plate 21 is longer than that of the square plate.

[0039] For the horizontal plate 21, a limit mechanism is placed on the horizontal plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com