Cylindrical Cup Lid Fast Hot Pressing Equipment

A hot-pressing equipment, cylindrical technology, applied in the field of rapid hot-pressing equipment for cylindrical cup lids, can solve problems such as insecurity, and achieve long service life, high processing efficiency, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

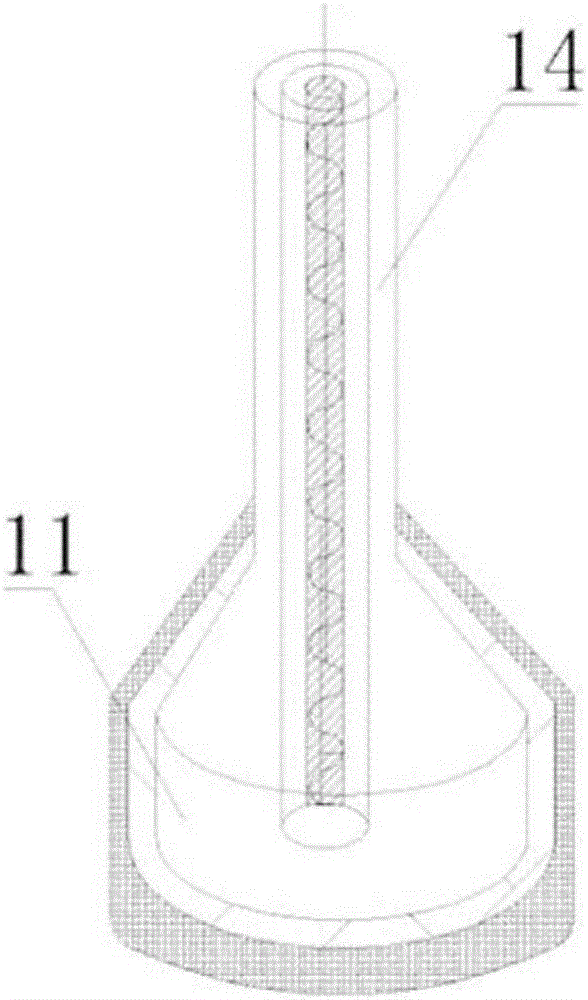

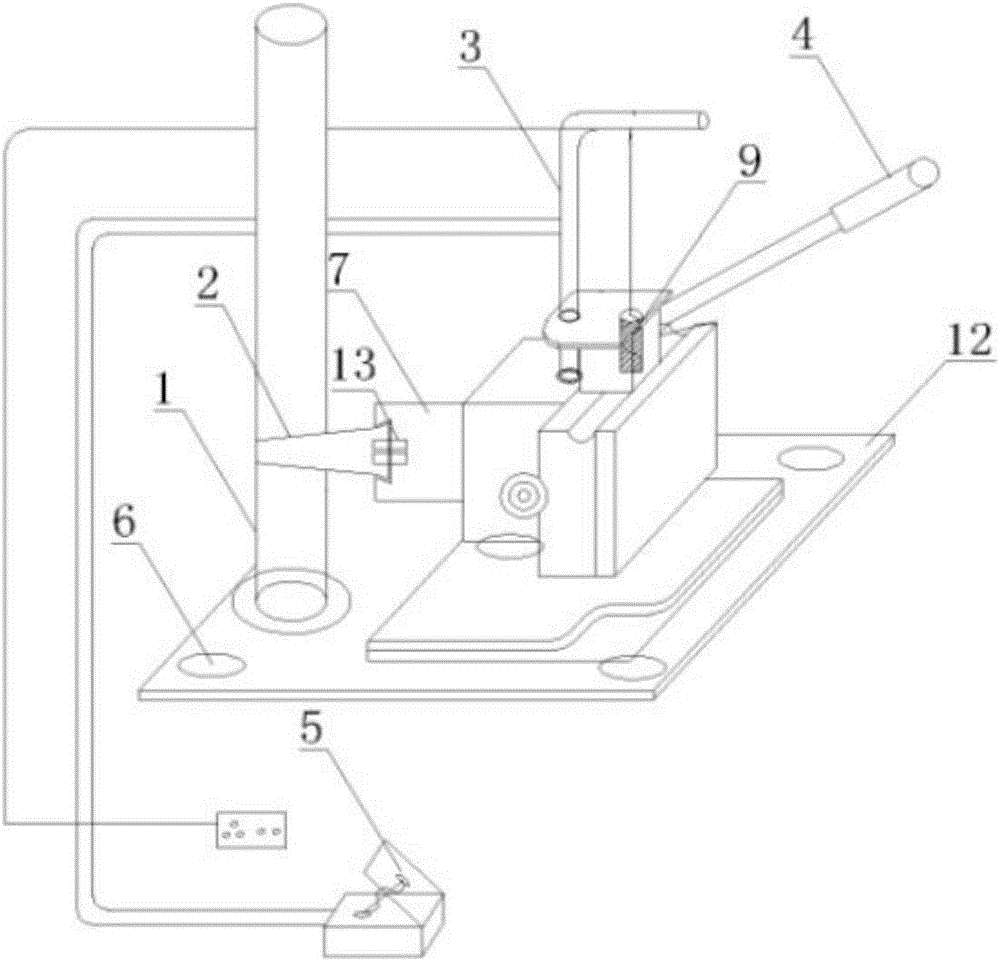

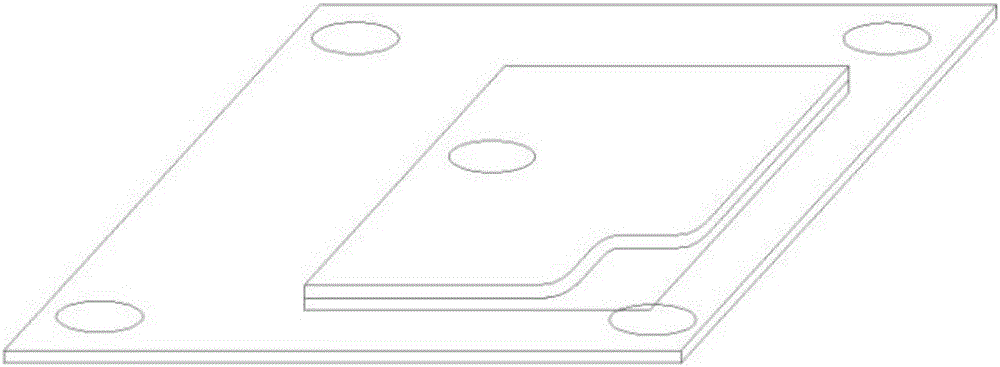

[0018] Referring to the accompanying drawings, the rapid heating and pressing equipment for cylindrical cup lids includes a vertical fixed table with a positioning suction cup, a liftable self-positioning slider, a cylindrical rapid heating pressure device, a controllable handle and a foot control switch. Wherein the positioning sucker vertical fixed platform is made of a positioning sucker 6, a horizontal fixing platform 12, and a cylindrical vertical polished rod 1. The liftable self-positioning slider is made up of an outer wedge-shaped trapezoidal slider 2, an inner wedge-shaped square slider 7, and a combination locking mechanism 13. The middle part of the cylindrical type rapid heating pressure device is connected with the inner wedge-shaped square slider 7, and moves up and down along with the rotation and adjustment of the controllable handle 4. The cylindrical type rapid heating pressure device consists of a hollow vertical cylinder 14, a thermocouple 9, a pneumatic he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com