Novel RGO/MXene composite film and preparation method thereof

A composite membrane, a new type of technology, applied in the field of materials, can solve the problems of increasing separation cost, increasing the risk of RGO shedding, and inability to determine the separation mechanism of MXene separation, and achieve the effect of improving hydrophilicity and retention rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

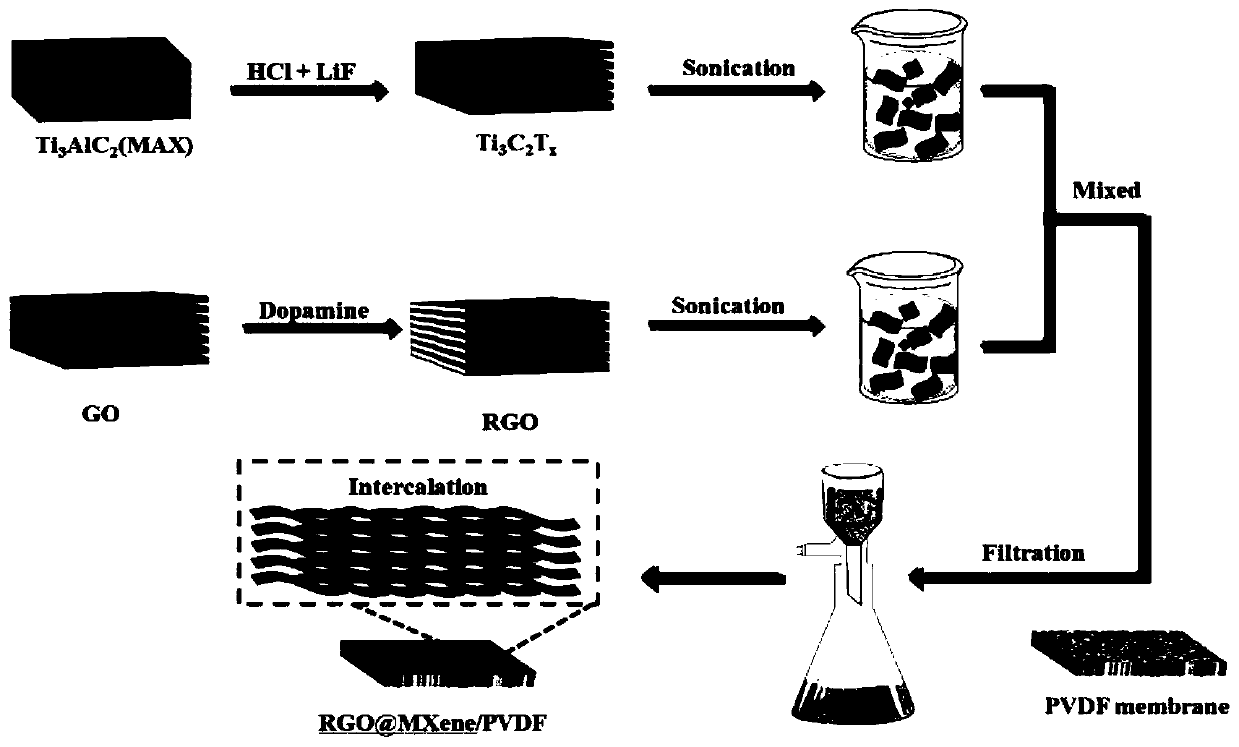

[0040] A novel RGO / MXene composite membrane:

[0041] (1) Preparation of MXene homogeneous solution: MXene two-dimensional materials were prepared by etching the MAX phase with LiF+HCl mixed reagent and ultrasonically assisted exfoliation, as follows: 1g Ti 3 AlC 2 and 1g of LiF powder were added to 10ml of HCl solution (mole fraction 9M), magnetically stirred at 35°C for 24h, and then the product was centrifuged and washed with deionized water at 3500rpm for several times until the pH of the solution supernatant was 6; The precipitate was shaken vigorously for 10 min, and centrifuged at 3500 rpm for 1 h to obtain a homogeneous MXene solution;

[0042] (2) Preparation of RGO: Dopamine is used to reduce and modify GO to prepare RGO, which expands the layer spacing of the material and provides more adsorption sites. Take 400mg and add it to the beaker; add 200ml of deionized water, and at the same time use an ultrasonic cleaner to ultrasonically disperse for 0.5h, so that GO i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com