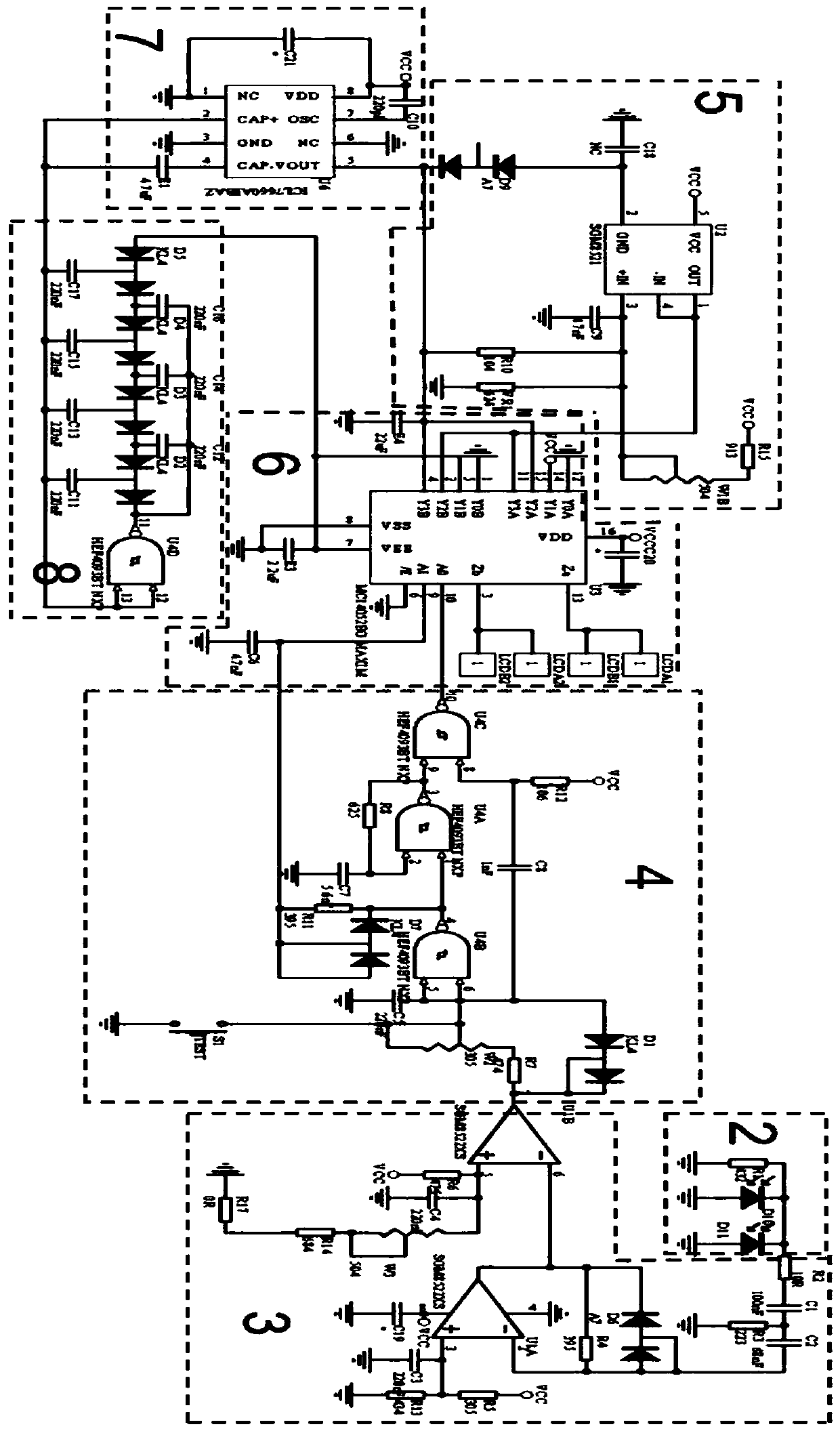

Control circuit of automatic light-changing welding mask

A welding mask and control circuit technology, applied in eye masks, ophthalmic surgery, instruments, etc., can solve the problems of sensitivity, lack of brightness adjustment, uneven quality, long response time, etc., to achieve convenient adjustment and setting, improve production efficiency, eliminate The effect of electro-optic ophthalmia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

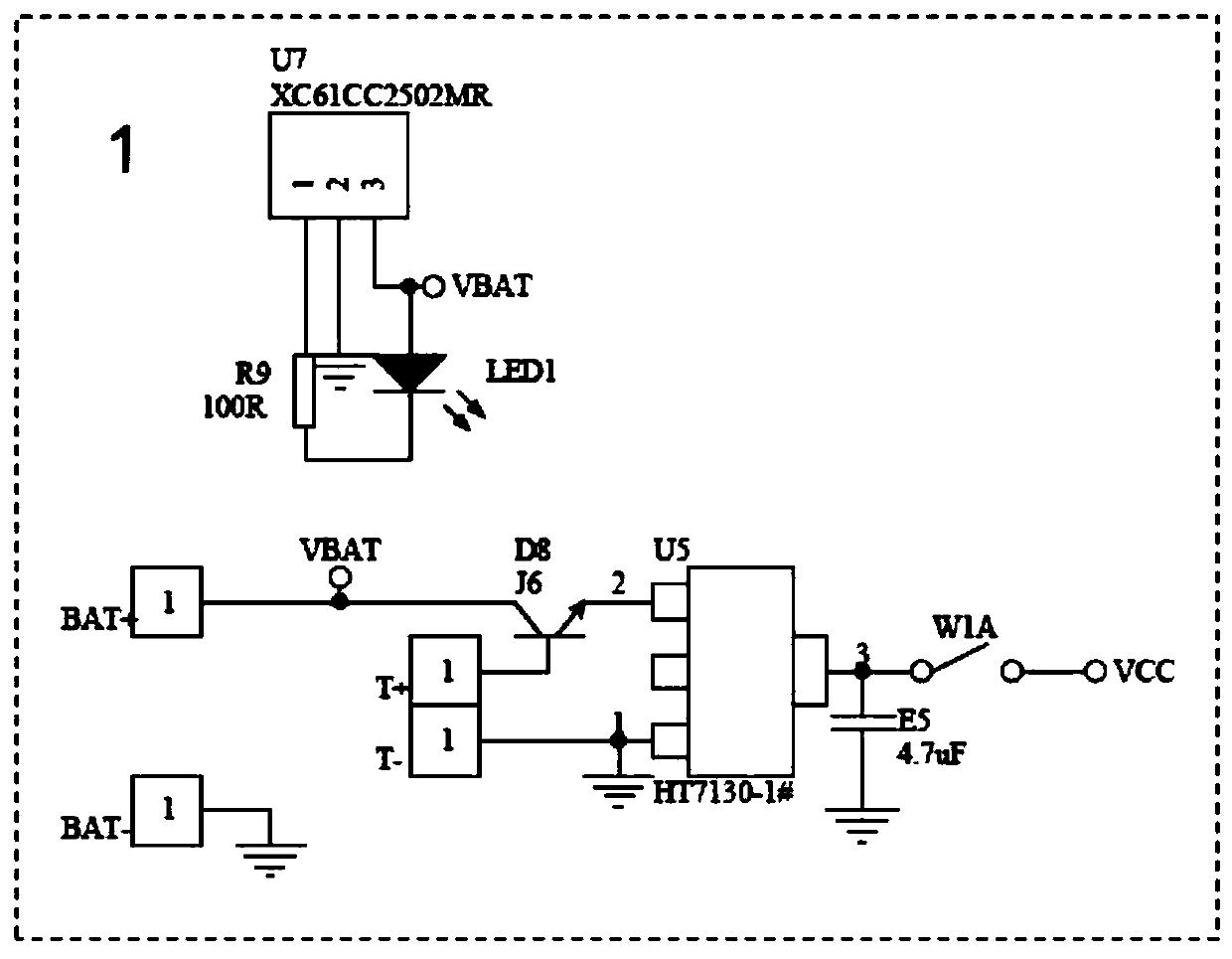

[0074] Example 1, the power supply voltage regulator circuit adopts the low power consumption linear voltage regulator chip U5 to reduce the power consumption caused by voltage regulation; as shown in the figure, T+ and T- are respectively connected to the positive and negative poles of the solar cell, and only when When there is light, the whole machine enters the working state, which further reduces the useless loss of battery power; the switch W1B adopts a resistance switch two-in-one potentiometer, and the switch of W1B can manually cut off the output of the voltage regulator chip.

Embodiment 2

[0075] Embodiment 2, the battery under-voltage reminder circuit adopts a dedicated low-voltage detection chip, and the low-voltage detection chip U7 adopts the chip XC61CC2502MR. When the voltage supplied to the chip is insufficient, the LED will light up to remind the user to replace the battery.

Embodiment 3

[0076] Embodiment 3, the photoelectric conversion circuit is composed of infrared photodiodes, and converts the infrared light signal in the welding light into an electrical signal, so that the following circuit can drive the LCD black screen in time, and protect the welder's naked eyes from strong light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com