High-strength steel plate antirust oil and preparation method thereof

A technology of high-strength steel plate and anti-rust oil, which is used in the petroleum industry, lubricating composition, additives, etc., can solve the problems of producing ash, destroying the surface morphology of the steel plate, affecting the quality of the steel plate by heating and stamping, and achieving the viscosity Increase, good lubrication effect, good metal protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

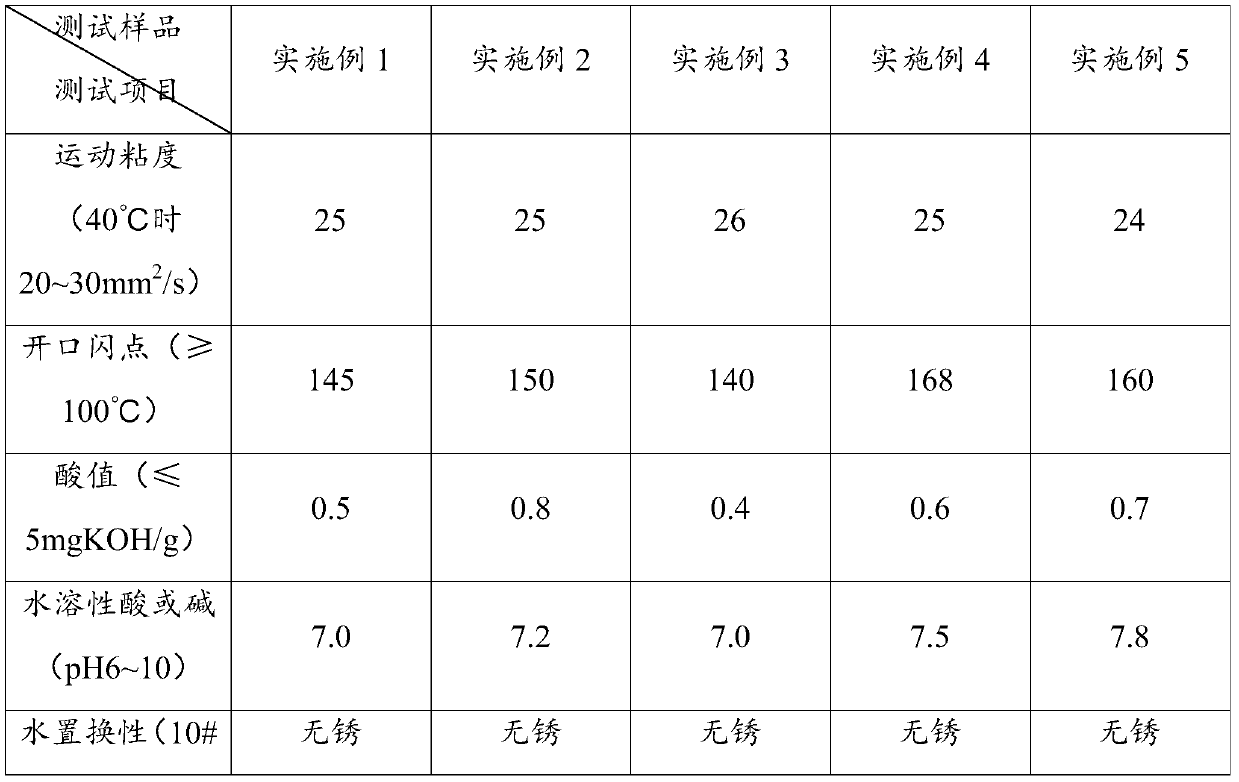

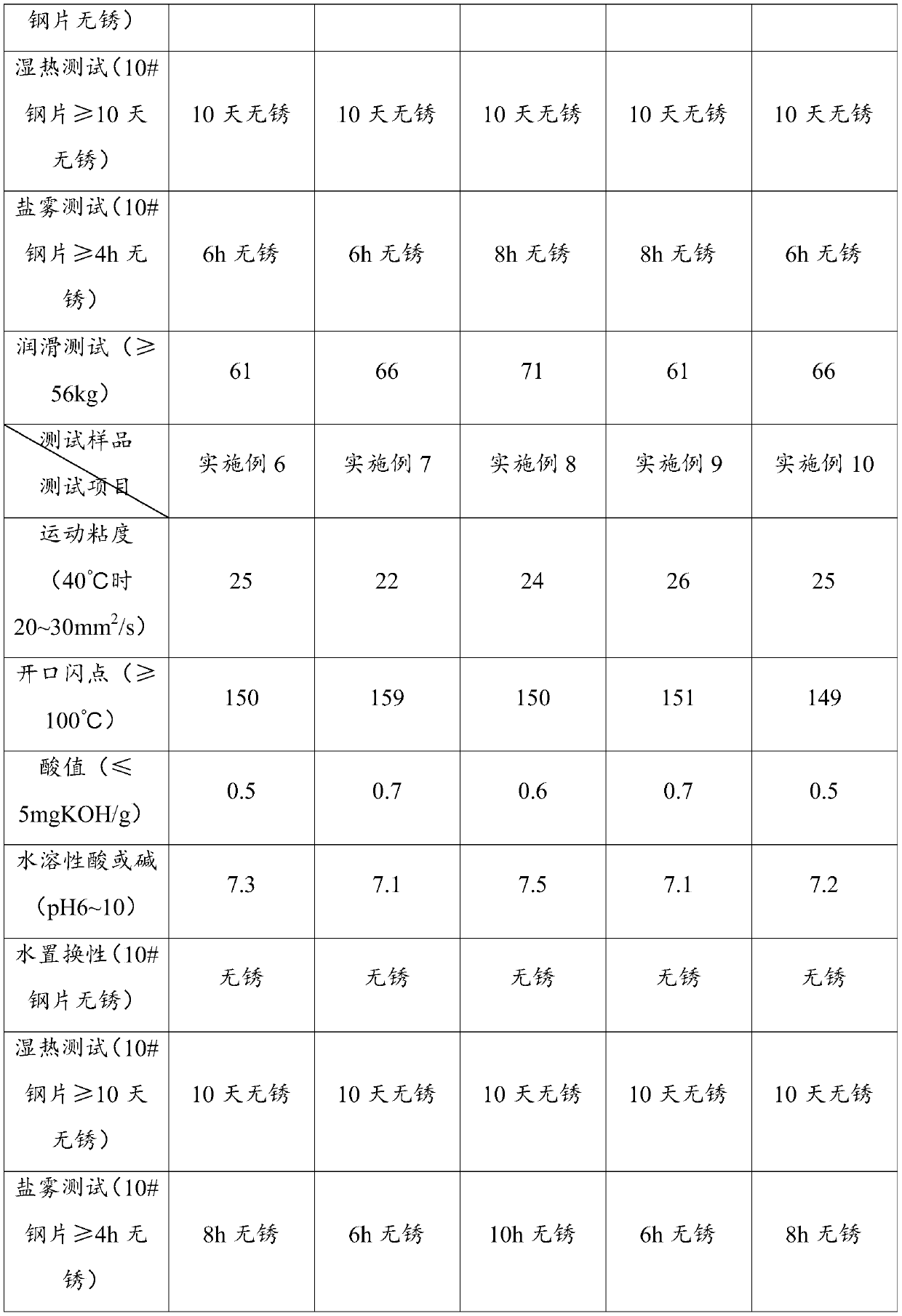

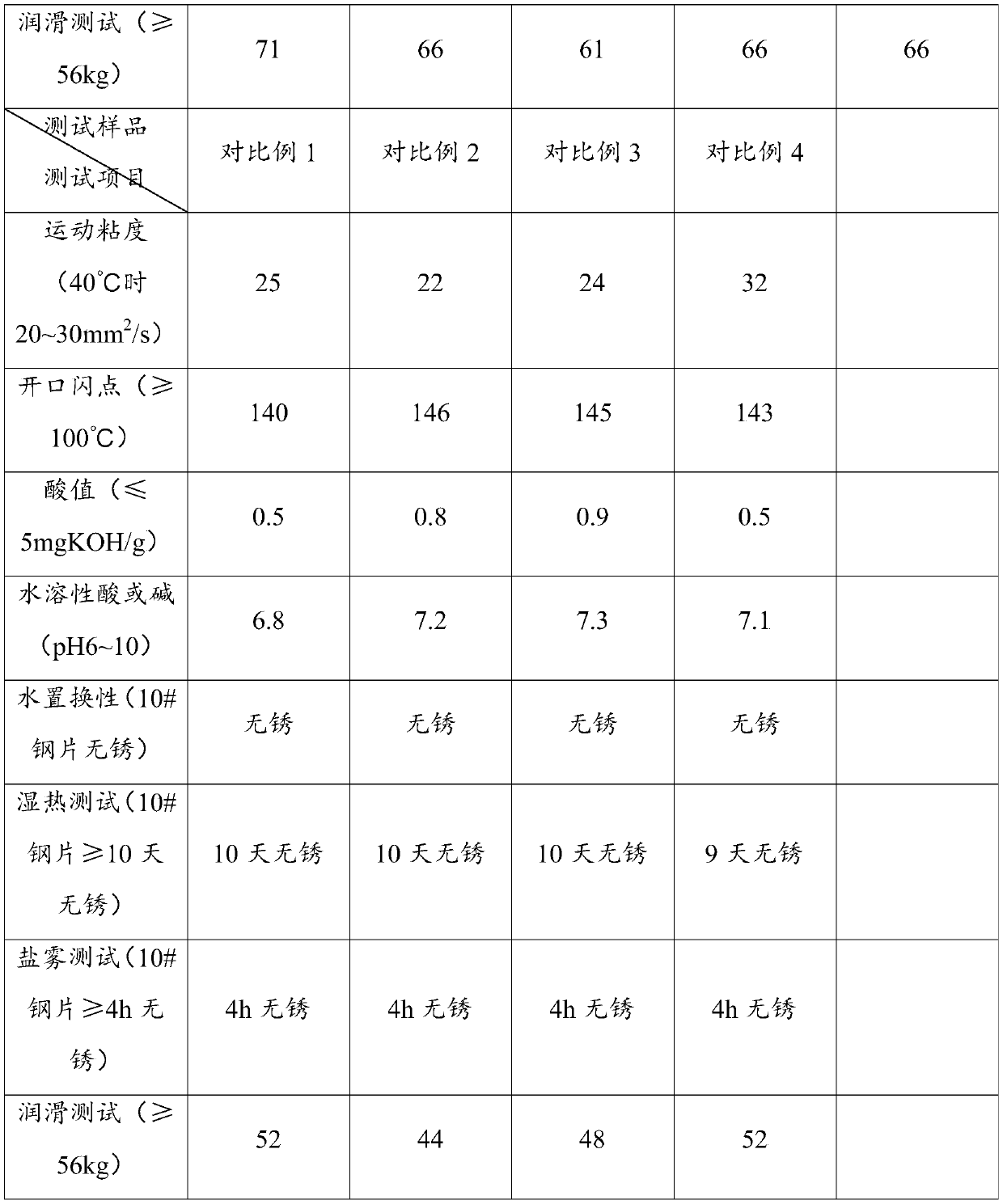

Examples

preparation example Construction

[0028] The embodiment of the present invention also provides a preparation method of high-strength steel plate anti-rust oil, comprising the following steps:

[0029] According to the above formula of high-strength steel plate anti-rust oil, weigh each component for later use; put the polymeric ester, synthetic ester, anti-rust additive and petroleum light distillate hydrocarbons into a container, heat to 60-80°C, stir and mix evenly That is, the high-strength steel plate antirust oil is obtained.

Embodiment 1

[0032] The high-strength steel plate antirust oil provided by the embodiments of the present invention is prepared by the following steps:

[0033] According to the following formula, each component by weight is taken for subsequent use: Polyester (at 100°C, its viscosity is 150mm 2 / s) 1g, synthetic ester (ester synthesized from C12 fatty acid and pentaerythritol) 20g, antirust additive (composite of C12 fatty acid and fatty amine) 2g, petroleum light distillate hydrocarbons (narrow distillate petroleum with a distillation range of 250-400°C) alkanes) 77g.

[0034] Put polymeric ester, synthetic ester, anti-rust additive and petroleum light distillate hydrocarbons into a container, heat to 60°C, stir and mix evenly.

Embodiment 2

[0036] The high-strength steel plate antirust oil provided by the embodiments of the present invention is prepared by the following steps:

[0037] According to the following formula, each component by weight is taken for subsequent use: Polyester (at 100°C, its viscosity is 200mm 2 / s) 5g, synthetic ester (ester synthesized from C12 fatty acid and propylene glycol) 15g, anti-rust additive (composite of C14 fatty acid and fatty amine) 5g, petroleum light distillate hydrocarbons (narrow distillate petroleum with a distillation range of 250-400°C) Alkanes) 75g.

[0038] Put polymeric ester, synthetic ester, anti-rust additive and petroleum light distillate hydrocarbons into a container, heat to 70°C, stir and mix evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com