Preparation method of submicron order core/shell structure PLGA (Poly(Lactic-co-Glycolic) microsphere with uniform particle size

A submicron-scale, shell-structured technology, applied in the field of tissue engineering and drug controlled release materials, can solve the problems of uneven size and complex methods, and achieve the effect of uniform particle size, simple preparation process and simple device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1. Dissolve 10mg of bovine serum albumin in 1mL of phosphate buffer to obtain solution 1; dissolve 30mg of PLGA and 24mg of F127 in 3mL of dichloromethane to obtain solution 2; mix 1mL of solution 1 with 3mL of solution 2. Ultrasonic dispersion in an ice bath with a power of 20W for 3 minutes to form colostrum;

[0019] 2. Add 4mL of colostrum to 10mL of calcium chloride solution with a concentration of 2mg / mL, and sonicate in an ice bath with a power of 50W for 10 minutes to form double emulsion;

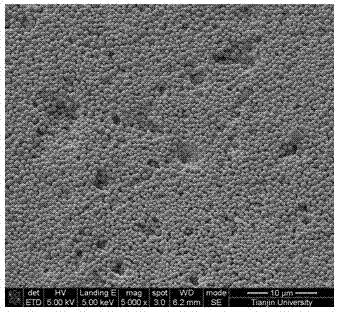

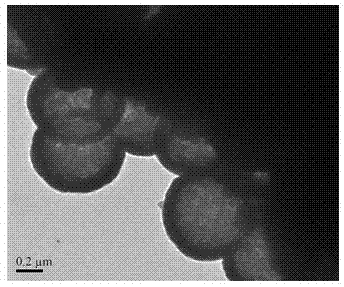

[0020] 3. After volatilizing the dichloromethane in the double emulsion at room temperature for 4 hours, dialyze in water for 4 hours, and freeze-dry to obtain a submicron-sized core / shell structure poly(lactide-co-ethylene glycol) with uniform particle size. lactide) (PLGA) microspheres, the particle size is about 500nm, and the encapsulation rate of bovine serum albumin is more than 30% (mass).

Embodiment 2

[0022] 1. Dissolve 30 mg of bovine serum albumin and 60 mg of carboxymethyl chitosan in 3 mL of phosphate buffer to obtain solution 1; dissolve 270 mg of PLGA and 90 mg of F127 in 9 mL of dichloromethane to obtain solution 2; Disperse 3mL of solution 1 and 9mL of solution 2 in an ice bath with a power of 30W and ultrasonically disperse for 3 minutes to form colostrum;

[0023] 2. Add 12mL of colostrum to 30mL of calcium chloride solution with a concentration of 1mg / mL, and sonicate in an ice bath with a power of 60W for 10 minutes to form double emulsion;

[0024] 3. After volatilizing the dichloromethane in the double emulsion at room temperature for 4 hours, dialyze in water for 4 hours, and freeze-dry to obtain a submicron-sized core / shell structure poly(lactide-co-ethylene glycol) with uniform particle size. Lactide) (PLGA) microspheres, the particle size is about 600nm, and the encapsulation rate of bovine serum albumin is more than 45% (mass).

Embodiment 3

[0026] 1. Dissolve 10 mg of bovine serum albumin and 50 mg of carboxymethyl chitosan in 1 mL of phosphate buffer to obtain solution 1; dissolve 90 mg of PLGA and 90 mg of F127 in 3 mL of dichloromethane to obtain solution 2; Disperse 1mL of solution 1 and 3mL of solution 2 ultrasonically in an ice bath for 3 minutes at a power of 20W to form colostrum;

[0027] 2. Add 4mL of colostrum to 12mL of calcium chloride solution with a concentration of 2mg / mL, and sonicate in an ice bath with a power of 50W for 10 minutes to form double emulsion;

[0028] 3. After volatilizing the dichloromethane in the double emulsion at room temperature for 4 hours, dialyze in water for 4 hours, and freeze-dry to obtain a submicron-sized core / shell structure poly(lactide-co-ethylene glycol) with uniform particle size. Lactide) (PLGA) microspheres, the particle size is about 600nm, and the encapsulation rate of bovine serum albumin is more than 40% (mass).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com