Steel pipe machining integrated equipment, control system and control method

A technology of control system and remote control system, which is applied in the field of steel pipe processing machinery and equipment, can solve the problems of low steel pipe processing efficiency, achieve the effects of solving low processing efficiency, improving processing efficiency, and improving the degree of equipment digitization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

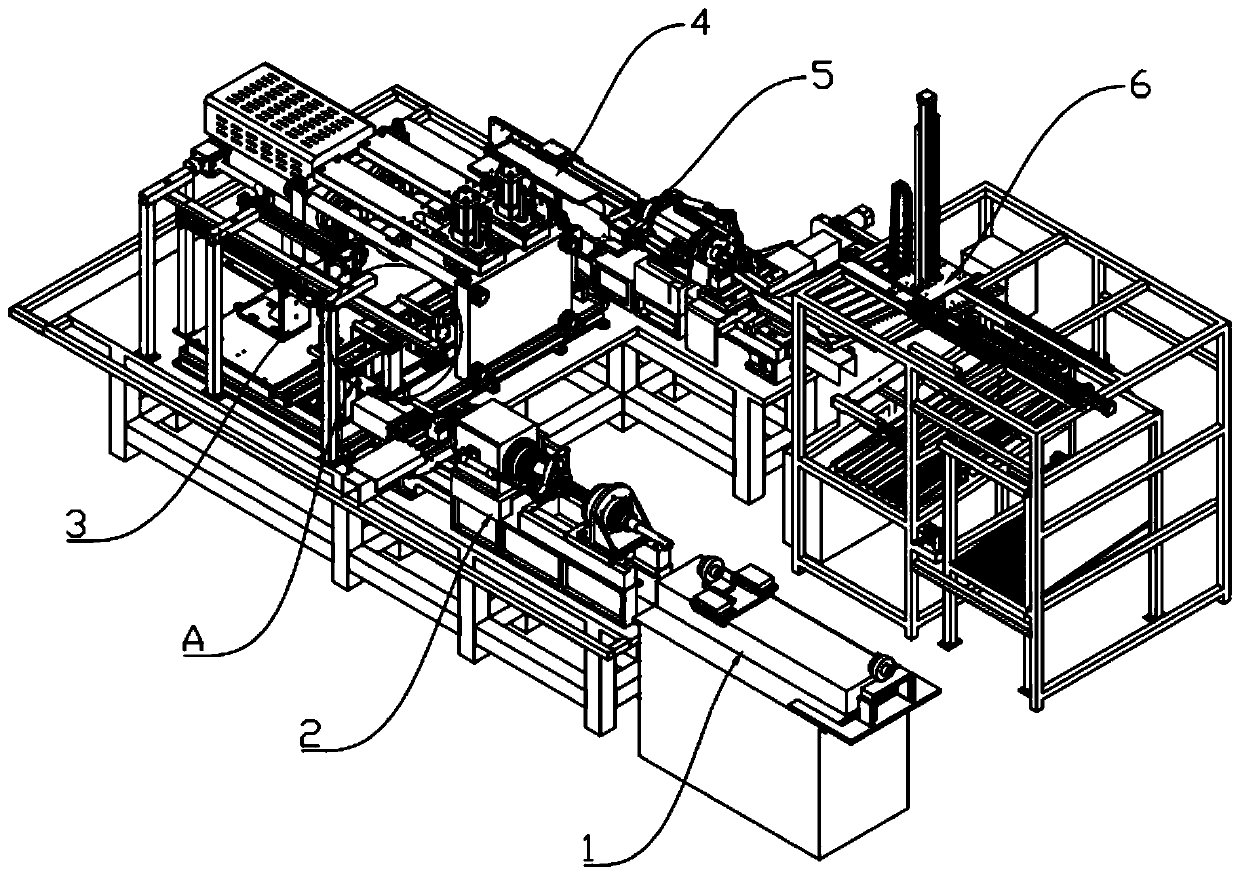

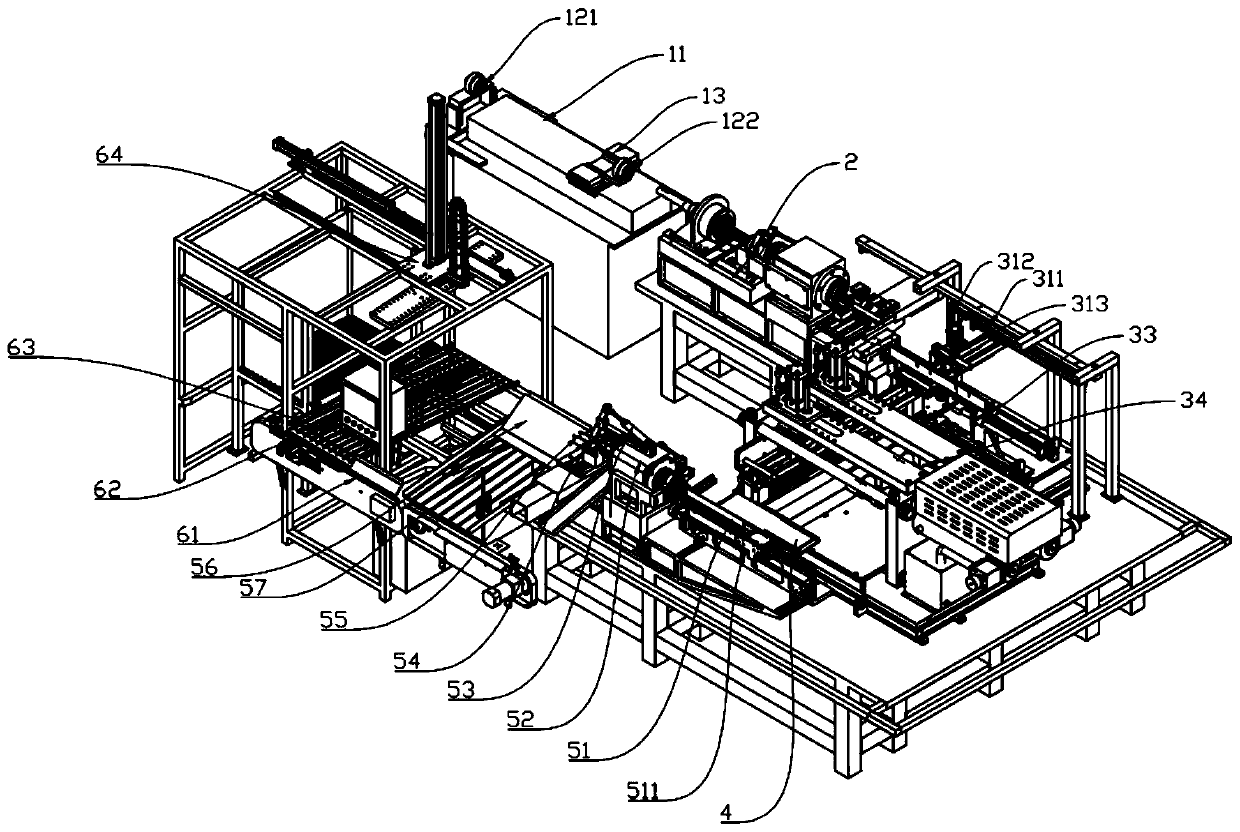

[0044] see figure 1 , the embodiment of the present invention provides an integrated equipment for processing steel pipes, including a workbench, on which a cutting device 2, a stamping device 3, and an outer circle processing device 5 are sequentially installed; and one end of the cutting device 2 is placed There is a feeding device 1, and an automatic picking device 6 is placed at one end of the outer circle processing device 5. The steel pipe is transferred from the feeding device 1 to the cutting device 2 for cutting and inner hole processing, and then clamped to the stamping device 3 for stamping, and then sent to the outer circle processing device 5 for outer circle processing, and finally sent to the automatic picking device 6 pairs The steel pipes are arranged in sequence and loaded into the feeding car. The direction from the feeding device 1 to the automatic picking device 6 is the direction of transmission of the steel pipes.

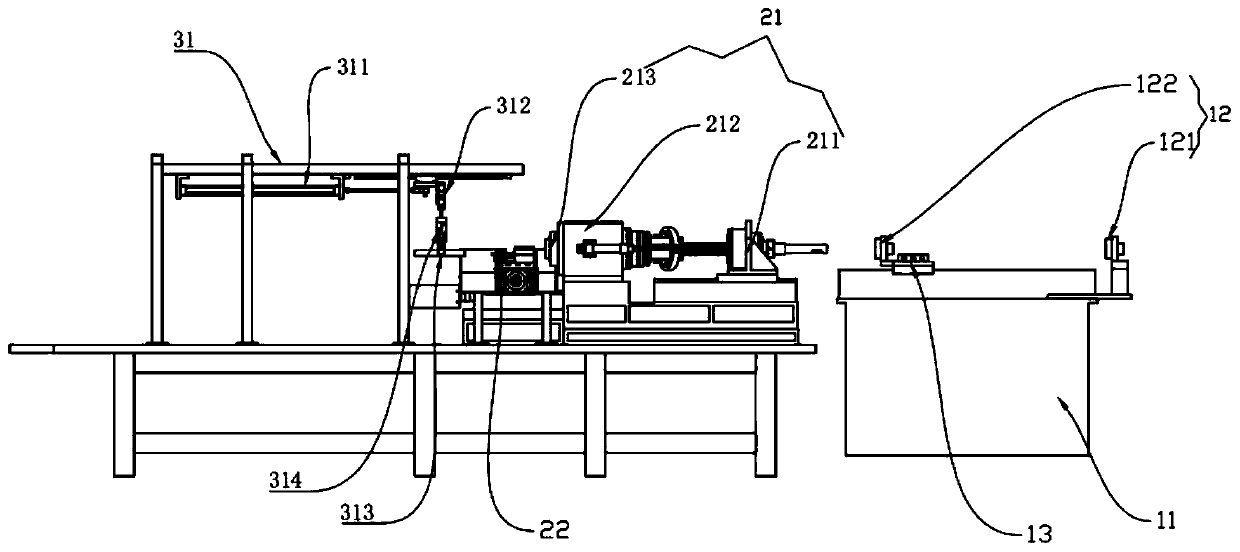

[0045] see figure 2 , the feeding d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com