Method for constructing cement soil underground continuous wall under complex geological condition

A technology of complex geological conditions and underground diaphragm walls, applied in sheet pile walls, infrastructure engineering, earth movers/shovels, etc., can solve the problems of difficult cutting, large equipment wear, slow construction progress, etc., to save cutting The effect of time, surface leveling, and reduction of construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

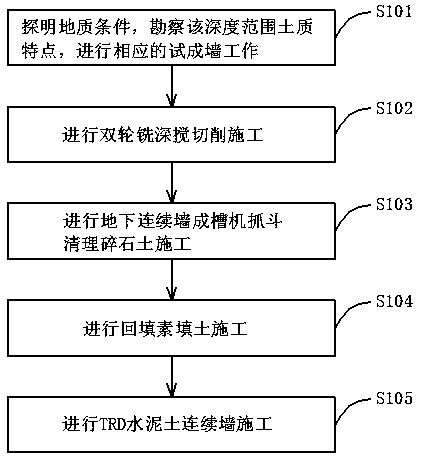

Method used

Image

Examples

Embodiment

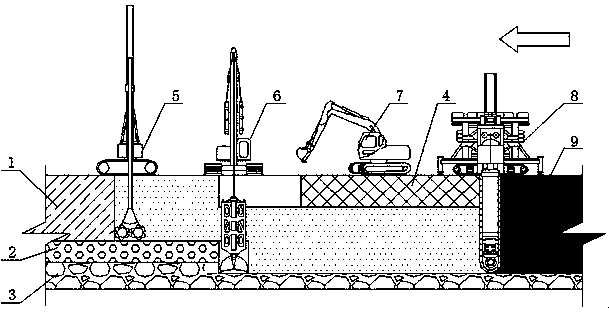

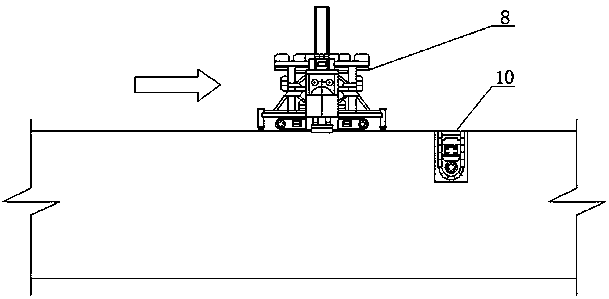

[0031] A specific application of the construction method of the diaphragm wall under cement soil under complex geological conditions of the present invention in the construction of a residential area. The residential area around the residential area has been built with a relatively high density residential area. The original construction stratum is divided into three depths from top to bottom. The first depth is mainly composed of cohesive soil, silt and sandy soil; the second depth is mainly composed of gravel soil; the third depth is mainly composed of impermeable layers 3 such as strongly weathered conglomerate and cohesive soil. The shape of the underground diaphragm wall is similar to "L", and the foundation pit adopts the support form of inserting H-shaped steel in the diaphragm wall under the cement soil with a thickness of 800mm and adding 1 to 2 rotary grouting anchor rods. The excavation depth of the foundation pit is 6.91-10.16m, the construction depth is 18.5m, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com