Modified sulfydryl-containing liquid silicone resin, non-toxic, colorless and odorless light-cured liquid silicone rubber and preparation method and application thereof

A liquid silicon and light-curing technology, which is applied in the field of non-toxic and tasteless light-curing silicone materials, can solve the problems of bad smell and high toxicity, and achieve the effects of moderate viscosity, fast curing speed and high application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

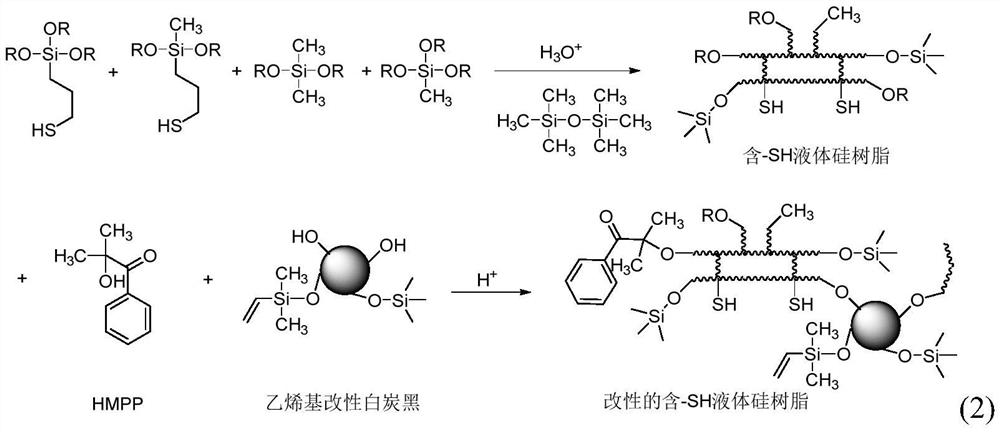

[0046] In some specific technical solutions of the present invention, a kind of preparation method of photocuring liquid silicone rubber prepolymer liquid is provided, and it comprises following preparation method:

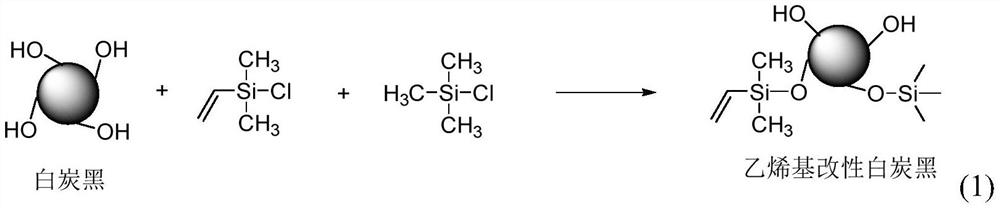

[0047] S1-1) Preparation of vinyl-modified silica

[0048]

[0049] The preparation of vinyl-modified silica is shown in formula (1).

[0050] Take white carbon black and dissolve it in a container with a solvent. After ultrasonic dispersion, add a composition of vinyl dimethyl chlorosilane and trimethyl chlorosilane under heating conditions. After the reaction is complete, dry under reduced pressure to obtain a surface covered with vinyl Modified silica powder.

[0051] Wherein, the solvent is one or more mixtures of n-hexane, cyclohexane, ethyl acetate, butyl acetate, and toluene; preferably, the solvent is n-hexane and ethyl acetate, and the mixing volume ratio is 1:1 .

[0052] Preferably, the silica is one or a mixture of fumed silica, precipitated sili...

Embodiment 1

[0075] A modified mercapto-containing liquid silicone resin and the corresponding non-toxic, colorless, and odorless light-cured liquid silicone rubber are respectively prepared by the following methods:

[0076] S1) Preparation of modified liquid silicone resin containing mercapto groups

[0077] S1-1) Preparation of vinyl-modified silica

[0078] Take 5.0g of fumed silica, 0.4g of trimethylchlorosilane and 0.1g of vinyl dimethylchlorosilane and add it to a 1:1 mixed solvent of 50g of n-hexane and ethyl acetate, ultrasonically disperse it for 10min, and at 40 °C for 4 hours, and vacuum-dried to obtain modified white carbon black powder.

[0079] S1-2) Preparation of modified mercapto-containing liquid silicone resin

[0080] Take 8g mercaptopropyltrimethoxysilane, 2g mercaptopropylmethyldimethoxysilane, 8g dimethyldimethoxysilane, 2g trimethoxysilane, 4.0g ultrapure water, 20g hexamethyldisilazane Ether (MM), 0.1 g of concentrated hydrochloric acid were stirred and reacted...

Embodiment 2

[0085] A modified mercapto-containing liquid silicone resin and the corresponding non-toxic, colorless, and odorless light-cured liquid silicone rubber are respectively prepared by the following methods:

[0086] S1) Preparation of modified mercapto-containing liquid silicone resin

[0087]S1-1) Preparation of vinyl-modified silica

[0088] Take 5.0g of fumed silica, 0.4g of trimethylchlorosilane and 0.1g of vinyl dimethylchlorosilane, and add it to a 1:1 mixed solvent of 50g of n-hexane and ethyl acetate, and ultrasonically disperse it for 10min. °C for 3 hours, and vacuum-dried to obtain modified white carbon black powder.

[0089] S1-2) Preparation of modified mercapto-containing liquid silicone resin

[0090] Take 6.0g mercaptopropyltrimethoxysilane, 4.0g mercaptopropylmethyldimethoxysilane, 5.0g dimethyldimethoxysilane, 5.0g trimethoxysilane, 5.0g ultrapure water, 30g six Methyldisiloxane (MM), 0.05g of concentrated hydrochloric acid was stirred and reacted at 40°C, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com