Sliding sash

A push-pull fan and fan base technology, which is applied to the wing frame, the layout of the wing, windows/doors, etc., can solve the problems of increasing assembly costs, wasting assembly time, increasing production costs, etc., and achieves easy installation and disassembly, and can be processed. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

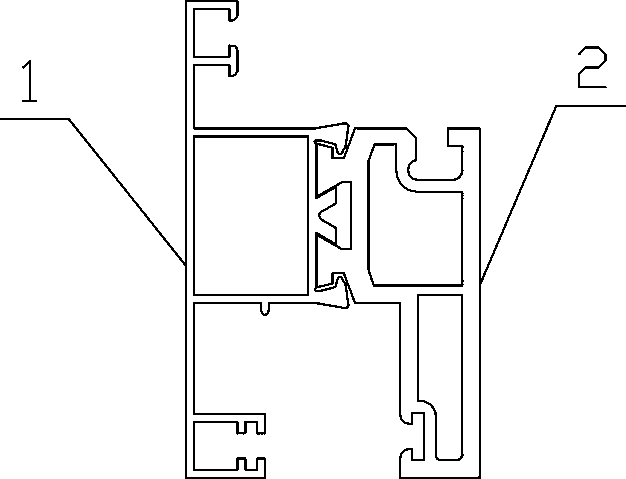

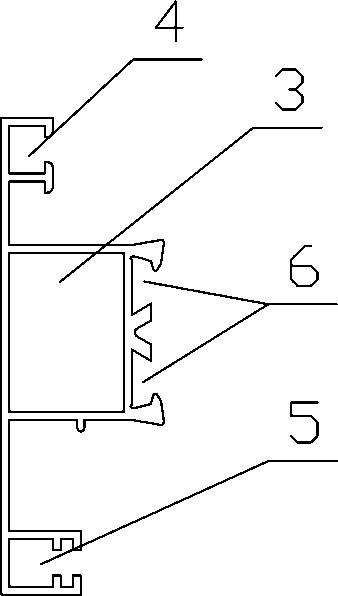

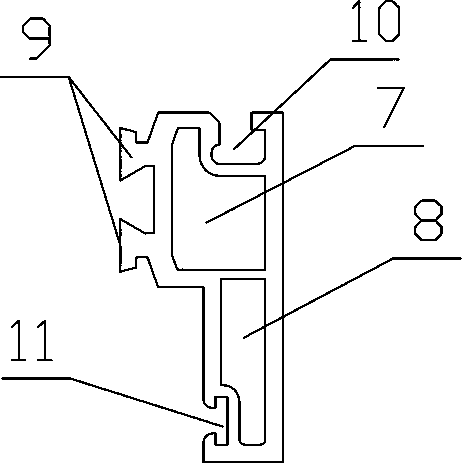

[0010] see Figure 1-3 , a push-pull fan in this embodiment, including a fan seat A1 and a fan seat B2, in particular: a rectangular cavity 3 is provided in the middle of the fan seat A1, a C-shaped opening 4 is provided at the top, and a door-shaped opening is provided at the bottom. Cavity 5, two C-shaped grooves 6 are vertically and symmetrically arranged on the right side of the rectangular cavity 3; the fan seat B2 has a vertically arranged inner cavity a7 and an inner cavity b8, and the length of the bottom side of the inner cavity a7 is Longer than the length of the top edge of the inner cavity b8, two clamp feet 9 are arranged vertically and symmetrically on the left side of the inner cavity a7, a groove 10 is provided on the upper part of the inner cavity a7, and a T is arranged at the lower left corner of the inner cavity b8. shaped groove 11.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com