Method for reducing and adsorbing heavy metal chromium by immobilized microorganisms

A technology of microbial agent and immobilized pellets, applied in the field of environmental biology, can solve the problems of high operating cost, low efficiency, secondary pollution of water and soil, etc., and achieve the effect of prolonging the use time and frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

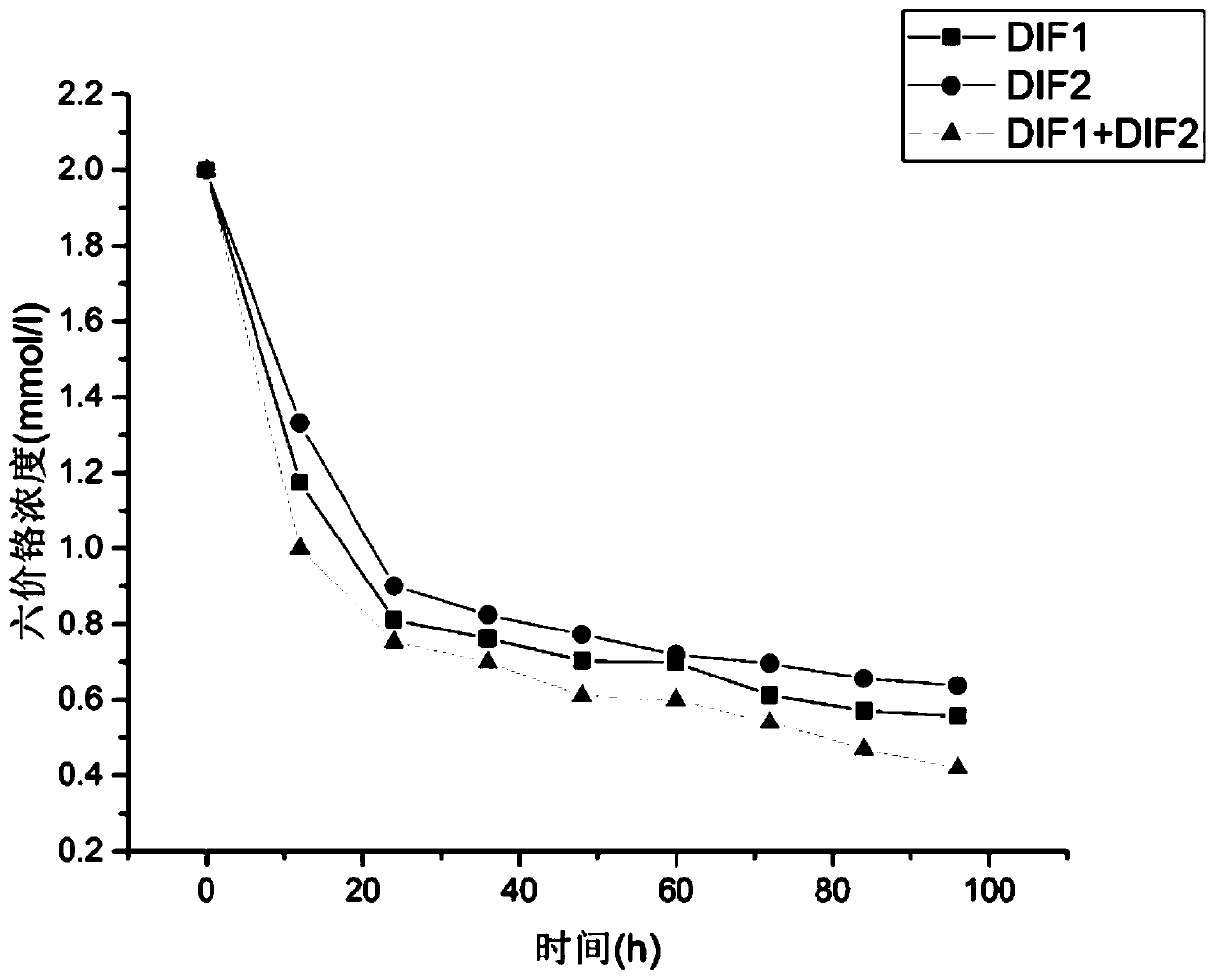

[0034] Example 1: Preparation of mixed microbial agent for reducing hexavalent chromium and chromium reduction experiment

[0035] (1) Preparation of mixed bacterial agent:

[0036] (1) Select two kinds of chromium-reducing bacteria, Bacillus cereus DIF1 and Rhodococcus rubrum DIF2, and inoculate them in LB liquid medium respectively; cultivate them for 8-12 hours at 28-30 degrees Celsius and 120 rpm, and the value of OD600 is 0.8 -1.0;

[0037] The LB medium formula is tryptone 10g / L, yeast extract 5g / L, sodium chloride 10g / L, pH7.0;

[0038] (2) choose each 10ml of two kinds of bacterial solutions to inoculate in 100ml of sterilized fresh medium, continue to cultivate for 8-12 hours under the conditions of step (1), the OD600 value reaches 1.0-1.2, and the bacterial solutions are for standby;

[0039] (2) Hexavalent chromium reduction experiment:

[0040] Verification experiment of Cr(VI) reducing ability of mixed bacterial agents: prepare LB solution, add 2mmol / L anhydro...

Embodiment 2

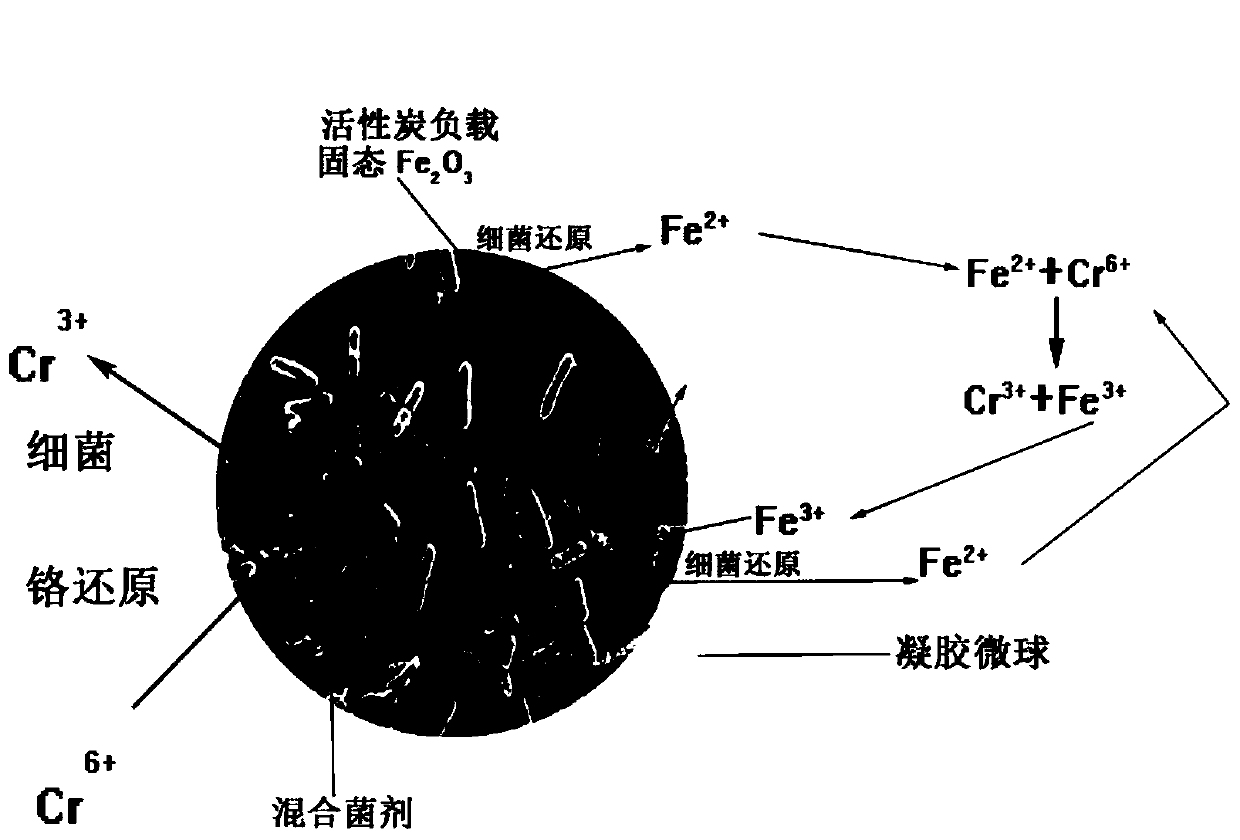

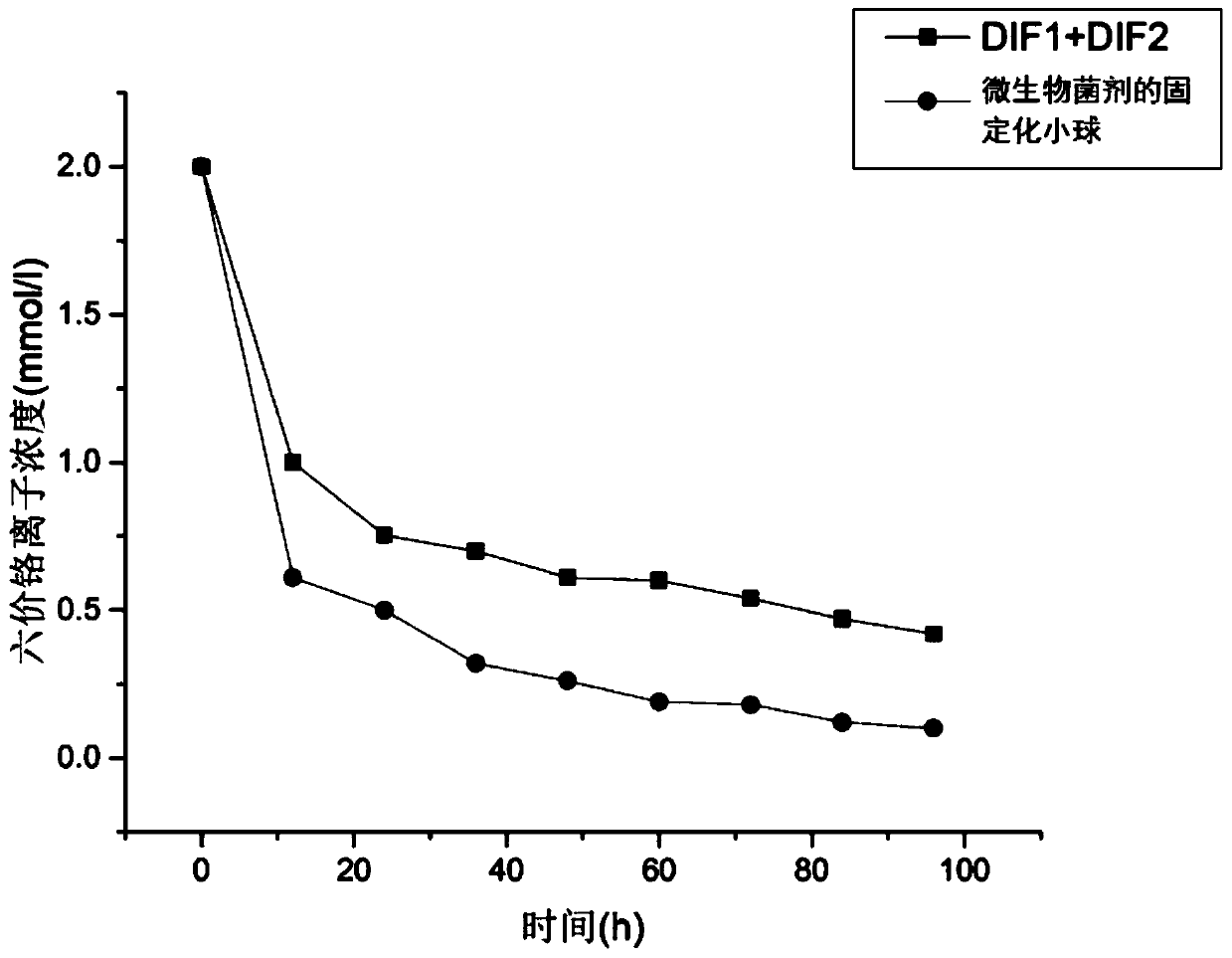

[0041] Embodiment 2: Preparation of gel microspheres and chromium reduction effect

[0042] (1) preparation of activated carbon loaded iron oxide, comprising the following steps:

[0043] (1) 40gFe(NO3) 3 9H 2 Dissolve O in 500mL of deionized water, add 2-4g of activated carbon, and stir;

[0044] (2) Add 500 mL of 1mol / L sodium hydroxide solution dropwise, stir, and when the pH of the solution is adjusted to between 7-8, stop adding sodium hydroxide dropwise;

[0045] (3) The precipitated product was centrifuged at 4000 g for 20 min, rinsed with pure water, centrifuged again, sterilized, and dried at 100 degrees Celsius for later use.

[0046] (2) Preparation of gel microspheres, comprising the following steps:

[0047] (1) Immerse the prepared activated carbon loaded with iron oxide in the bacterial agent suspension culture solution in a mass ratio of 1.8-2.5% for 8-12 hours;

[0048](2) adding alginic acid of 2-3% mass concentration and polyvinyl alcohol of 2-3% mass c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com