Free radical, moisture and UV triple curable sealant and preparation method thereof

A triple curing and sealant technology, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of high temperature, long curing time, high volatile content, etc., and achieve the effect of reducing the initiation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

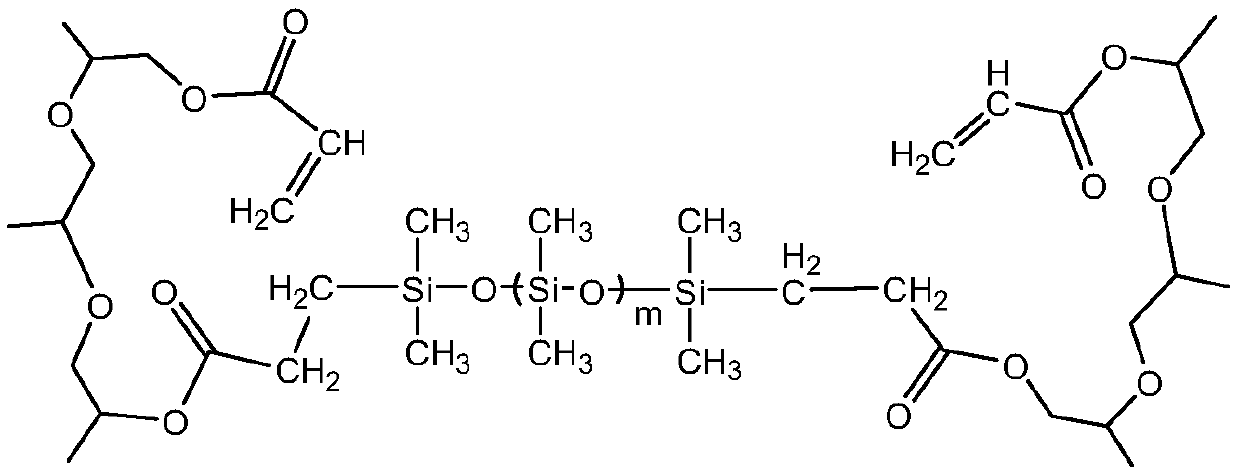

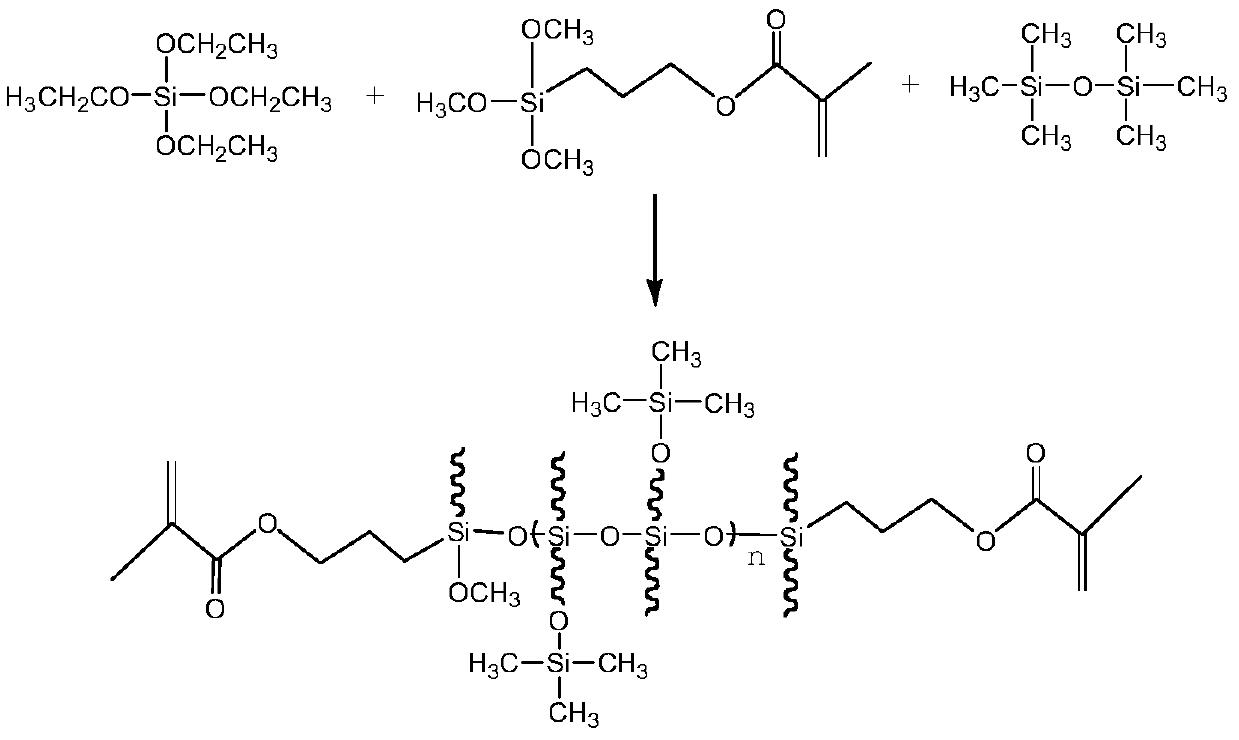

Method used

Image

Examples

Embodiment 1

[0031] Functional MQ resin, functional methyl silicone oil, vinyltrimethoxysilane, spherical hollow glass microspheres (true density 0.38~0.42g / cm 3 , particle size D90 is 40-70μm), white carbon black (specific surface area is 160-200m 2 / g of hydrophobic silica), benzoyl peroxide, dibutyltin dilaurate, 2-hydroxy-2-methyl-1-phenyl-1-acetone, black color paste according to 20:30:3: Mix in a weight ratio of 10:5:3:2:1:0.03. After vacuum defoaming, it was cured at 100°C for 0.5h. The performance of the sample is shown in Table 1, and the test method is shown in Table 1.

Embodiment 2

[0033] Functional MQ resin, functional methyl silicone oil, vinyltrimethoxysilane, spherical hollow glass microspheres (true density 0.38~0.42g / cm 3 , particle size D90 is 40-70μm), white carbon black (specific surface area is 160-200m 2 / g of hydrophobic silica), benzoyl peroxide, dibutyltin dilaurate, 2-hydroxy-2-methyl-1-phenyl-1-acetone, black color paste according to 20:30:3: Mix in a weight ratio of 10:5:3:2:1:0.03. After vacuum defoaming, first cure at 100°C for 0.5h, and then place it in room temperature and 50% humidity environment for 2h. The performance of the sample is shown in Table 1, and the test method is shown in Table 1.

Embodiment 3

[0035] Functional MQ resin, functional methyl silicone oil, vinyltrimethoxysilane, spherical hollow glass microspheres (true density 0.38~0.42g / cm 3 , particle size D90 is 40-70μm), white carbon black (specific surface area is 160-200m 2 / g of hydrophobic silica), benzoyl peroxide, dibutyltin dilaurate, 2-hydroxy-2-methyl-1-phenyl-1-acetone, black color paste according to 20:30:3: Mix in a weight ratio of 10:5:3:2:1:0.03. After vacuum defoaming, first cure at 100°C for 0.5h, and then under natural light for 2h, the performance of the sample is shown in Table 1, and the test method is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| True density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com