Solvent-free single-component polyurethane waterproof coating and preparation method thereof

A polyurethane waterproof, one-component technology, applied in the field of coatings, can solve the problems of rising coating viscosity and unfavorable construction, and achieve the effects of improving viscosity, convenient construction and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

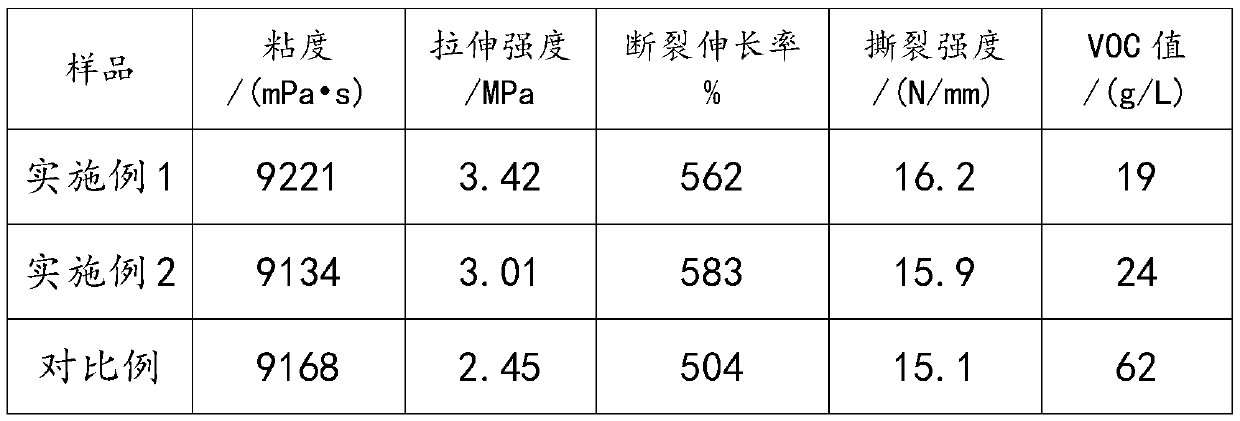

Examples

Embodiment 1

[0019] This embodiment provides a solvent-free one-component polyurethane waterproof coating, which includes the following components in parts by weight: 35 parts of mixed polyether polyols, 12 parts of diphenylmethane diisocyanate, 9 parts of hexamethylene diisocyanate, three 15 parts of glycerol acetate, 12 parts of acetyl tributyl citrate, 5 parts of 1-butyl-3-methylimidazolium dicyanamide salt, 30 parts of calcium oxide, 20 parts of titanium dioxide, 1 part of single-layer graphene , 0.5 parts of dibutyltin silicate catalyst in February;

[0020] The mixed polyether polyol is a mixture of polyether DL-2000D, polyether EP-330N and hydroxyl-terminated polybutadiene R-15M, and the mass ratio of the three is 3:2:0.8; the mixed polyether polyol The hydroxyl value of alcohol is 0.43; the molecular weight of the hydroxyl-terminated polybutadiene prepolymer is 2213Mn, and the hydroxyl value is 0.51; the dibutyltin dilaurate catalyst is the glycerol triacetate solution of dibutylti...

Embodiment 2

[0028] This embodiment provides a solvent-free one-component polyurethane waterproof coating, comprising the following composition in parts by weight: 50 parts of mixed polyether polyols, 10 parts of diphenylmethane diisocyanate, 10 parts of hexamethylene diisocyanate, three 20 parts of glycerol acetate, 15 parts of acetyl tributyl citrate, 8 parts of 1-butyl-3-methylimidazolium dicyanamide salt, 40 parts of calcium oxide, 15 parts of titanium dioxide, 2 parts of single-layer graphene , 1 part of dibutyltin silicate catalyst in February;

[0029] The mixed polyether polyol is a mixture of polyether DL-2000D, polyether EP-330N and hydroxyl-terminated polybutadiene R-15M, and the mass ratio of the three is 3:2:0.6; the mixed polyether polyol The hydroxyl value of alcohol is 0.42; The molecular weight of the hydroxyl-terminated polybutadiene prepolymer is 2213Mn, and the hydroxyl value is 0.51; The dibutyltin dilaurate catalyst is the glycerol triacetate solution of dibutyltin di...

Embodiment 3

[0032]This embodiment provides a solvent-free one-component polyurethane waterproof coating, comprising the following components in parts by weight: 40 parts of mixed polyether polyols, 12 parts of diphenylmethane diisocyanate, 8 parts of hexamethylene diisocyanate, three 18 parts of glycerol acetate, 12 parts of acetyl tributyl citrate, 5 parts of 1-butyl-3-methylimidazolium dicyanamide salt, 30 parts of calcium oxide, 20 parts of titanium dioxide, 3 parts of single-layer graphene , 0.8 parts of dibutyltin silicate catalyst in February;

[0033] The mixed polyether polyol is a mixture of polyether DL-2000D, polyether EP-330N and hydroxyl-terminated polybutadiene R-15M, and the mass ratio of the three is 3:2:1; the mixed polyether polyol The hydroxyl value of alcohol is 0.44; the molecular weight of the hydroxyl-terminated polybutadiene prepolymer is 2213Mn, and the hydroxyl value is 0.51; the dibutyltin dilaurate catalyst is the glycerol triacetate solution of dibutyltin dila...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com